Workshop services for stock preparation

Maximize operational efficiency through advanced reconditioning solutions

Valmet’s modular maintenance solutions for stock preparation equipment offer board- and papermakers clear options that can be mixed and matched to create the exact combination of services you need. These solutions consist of maintenance, reconditioning and upgrade services for equipment efficiency and usability, fiber quality, energy-efficiency, sustainability and work safety.

Secured equipment efficiency

Improved quality

Minimize unplanned shutdowns

Reduced carbon footprint

Your trusted OEM Partner for stock preparation equipment

Valmet is the preferred OEM partner for workshop services for stock preparation equipment. With workshop service modular maintenance solutions, you can achieve the optimal level of service required for the trouble-free running of your production. Valmet offers modular maintenance solutions for refining, pulping and screening areas.

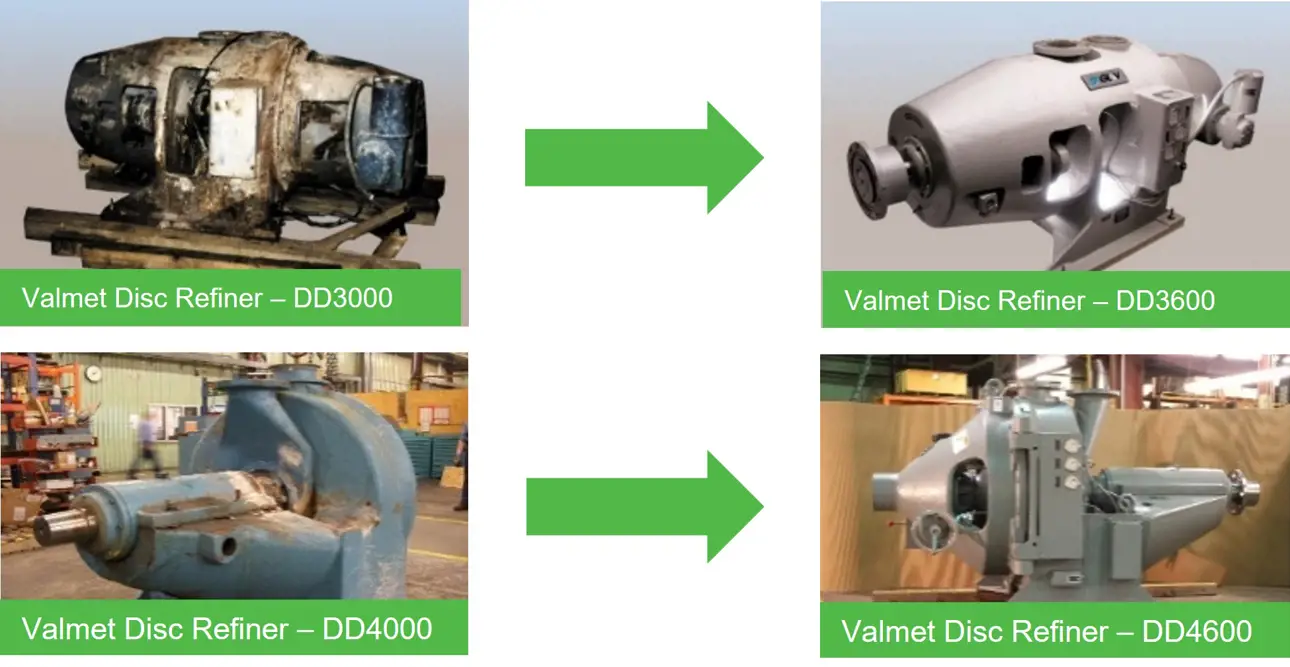

In 2019, Valmet acquired legacy manufacturers GL&V and J&L Fiber services, which joined the technology leaders in three separate areas of refining: disk refiner technology; conical refiner technology; and low-consistency refiner segment technology.

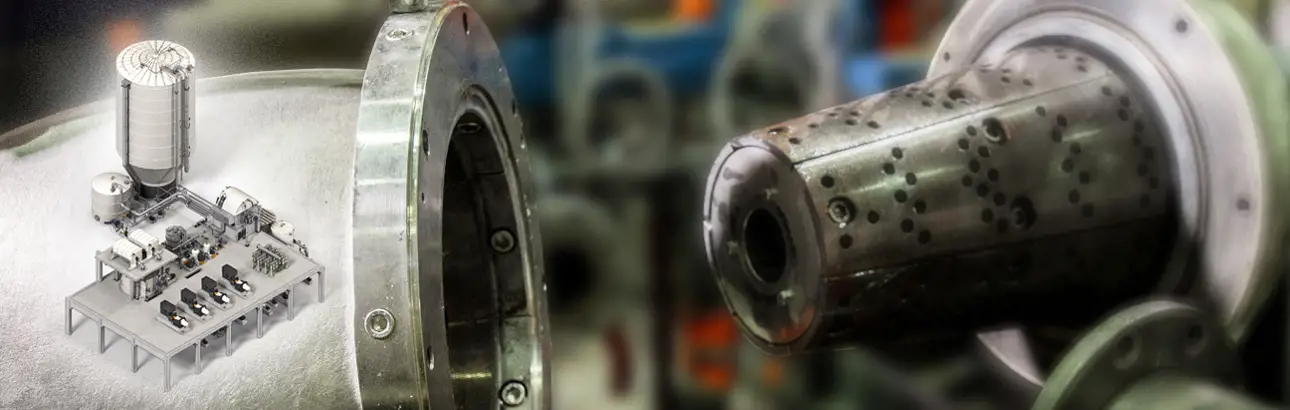

Workshop services for LC refining and deflaking – Valmet Conical Refiner – Conflo and Valmet Conical Refiner - Pro

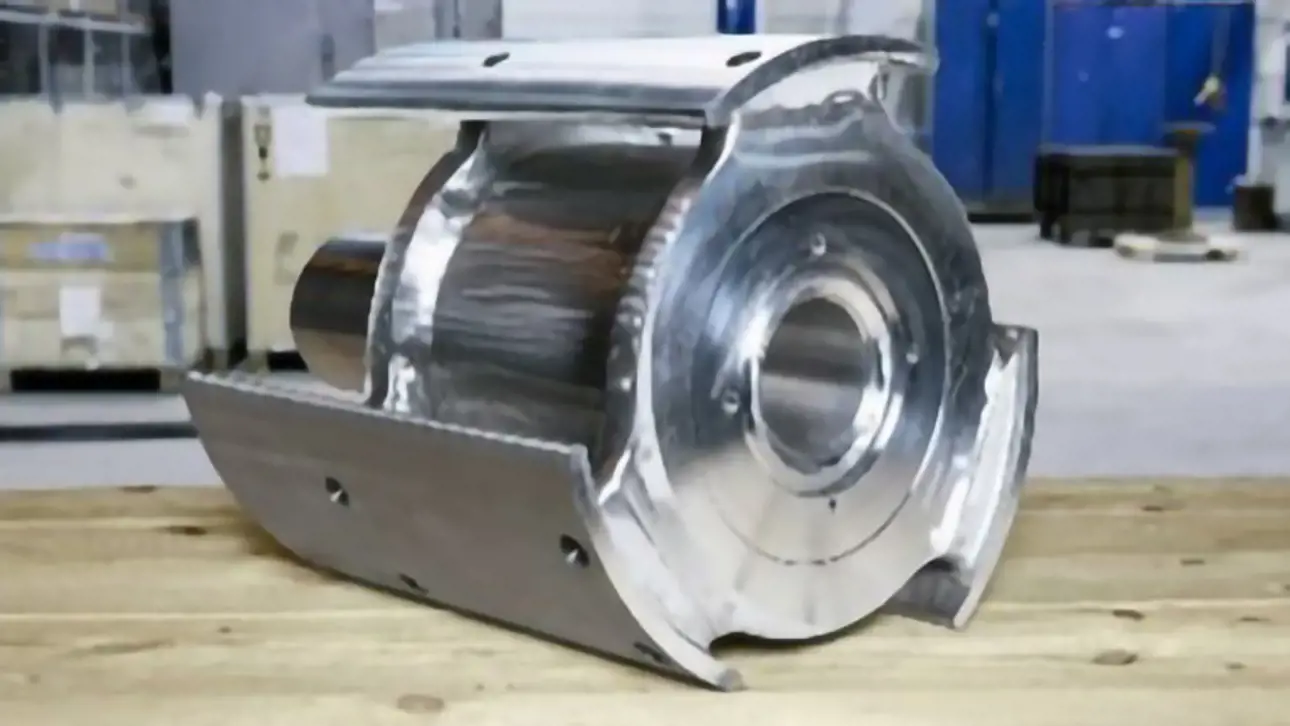

Valmet offers a wide range of reconditioning for low-consistency (LC) conical refiners, as well as refiner auxiliaries. Valmet Conical Refiner reconditioning consists of a basic maintenance scope and possible additional services. This basic scope includes a series of activities to return a refiner to full performance. If all the refiner’s main parts are not repairable, extra services are needed to replace or recondition worn components.

Refiner reconditioning keeps the machine running smoothly as good as new. Utilizing the latest improvements makes improved performance possible. Upgrades such as improved components or remote control and monitoring systems offer maximized reliability and possibilities of process improvements.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

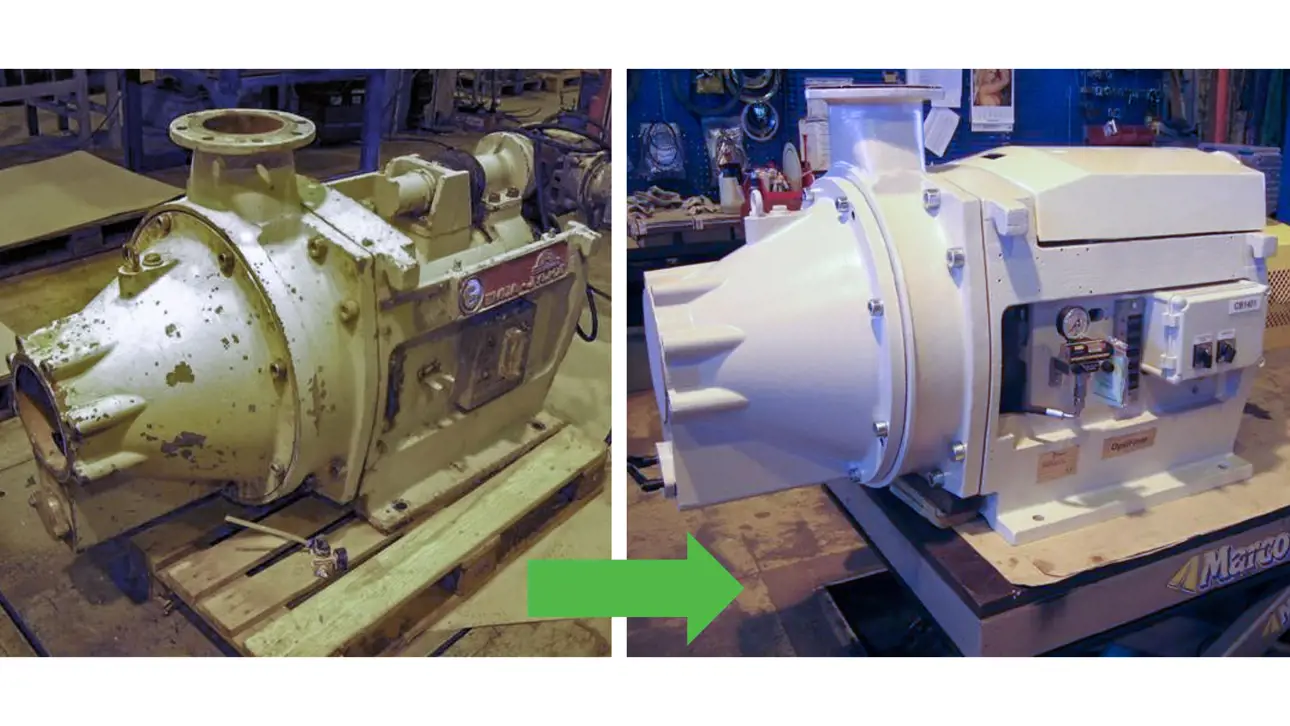

CONTACT USWorkshop services for LC refining and deflaking – Valmet Disk Refiner - DD

Valmet offers a wide range of reconditioning for low-consistency (LC) disk refiners, as well as refiner auxiliaries. Valmet Disk Refiner Reconditioning consists of a basic maintenance scope and possible additional services. This basic scope includes a series of activities to return the disk refiner to full performance. If all the refiner’s main parts are not repairable, additional services are needed to replace or recondition worn components.

Refiner reconditioning keeps the machine running smoothly as good as new. Valmet Disk Refiner Upgrade covers selectable upgrades that can help you with equipment efficiency and usability, fiber quality, energy efficiency, sustainability, and work safety.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

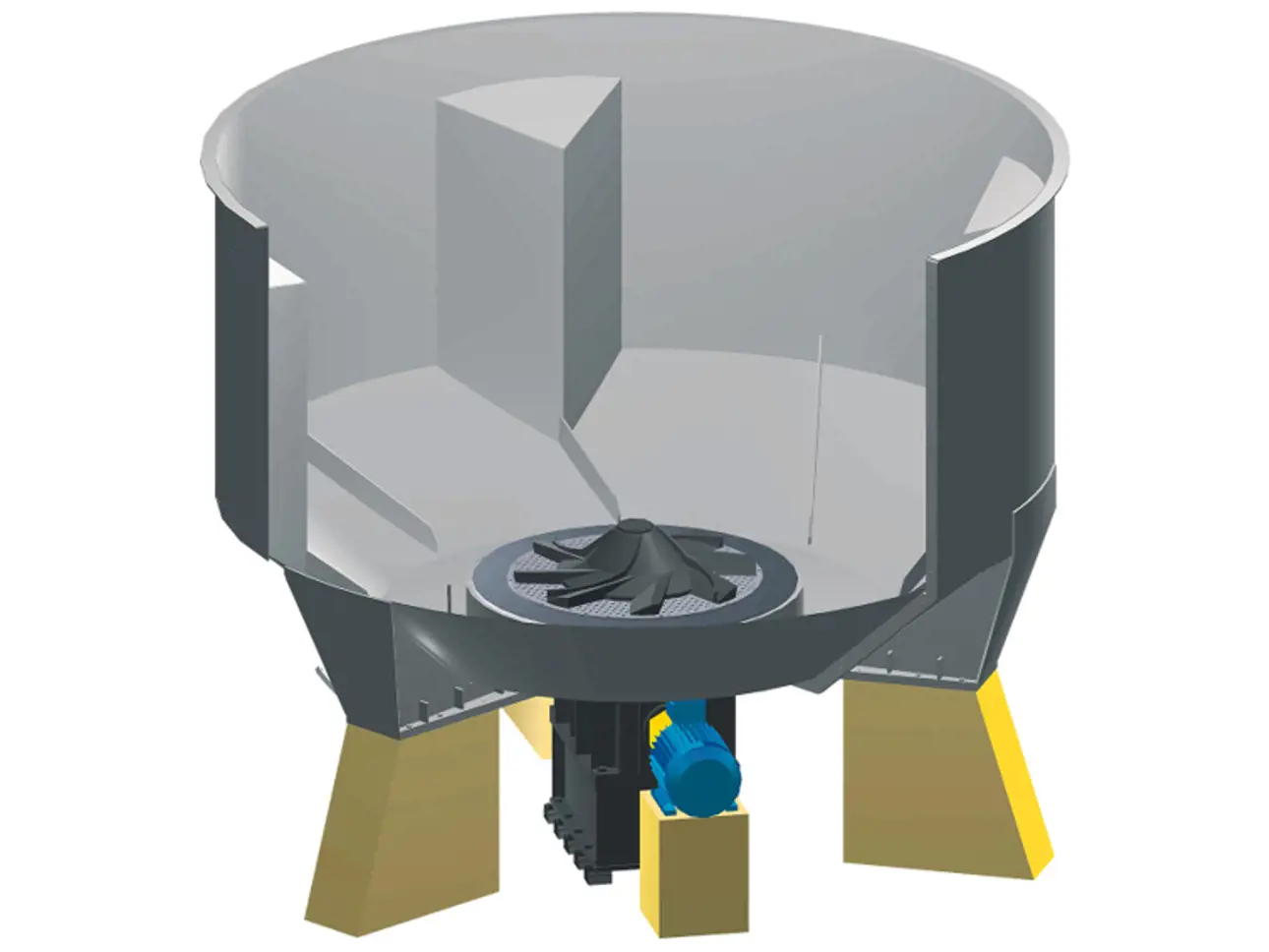

CONTACT USWorkshop services for pulping

Valmet’s bale pulpers and under-the-machine pulpers represent the most advanced pulping technology that meets the highest requirements to ensure reliable production with the optimal performance and cost-effective availability needed in stock preparation production.

Pulper rotor units, bearing units and rotors need periodic reconditioning, and for guaranteed pulper availability, spare units are needed. Valmet offers a full range of workshop services for pulpers: reconditioning services; pulper and rotor upgrades; and exchange unit services.

Questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

CONTACT USWorkshop services for screening

Screening is essential for cleanliness, fiber quality and fiber loss. Valmet’s screening for coarse, fractionation, fine and machine screening responds to all these challenges in stock preparation production.

Workshop services offer vital maintenance solutions for the screening. Complete screen overhauls with the latest upgrades guarantee the optimal screening performance. Standard bearing unit reconditioning or exchange units are the basis for maintaining the screens. Rotors are reconditioned with standard foils or upgraded ones, depending on the target of the workshop services scope.

Valmet Oil Monitoring for stock preparation equipment

Most bearing failures occur due to insufficient lubrication. Insufficient lubrication typically arises from missing or contaminated lubricant.

The traditional indications of bearing failure are increased vibration and temperature. These can be considered lagging indicators because failures have already progressed when they arise.

Valmet offers intelligent solutions for oil monitoring. Using oil quality as the leading indicator supports a predictive maintenance approach.

Benefits:

- Early warning of oil contamination or degradation

- Avoid expensive bearing failures and unplanned shutdowns

- Detect leakages in the lubrication system

- Warning signal about misoperation

- Remote services from Valmet (optional)

Read more about oil monitoring for fiber processing equipment.

Exchange unit agreement – a powerful risk management tool

Finding a balance between risk and costs in the spare equipment inventory can be difficult. Valmet’s Exchange Unit Agreement is an alternate solution that eliminates the need to purchase your own spare equipment. The agreement ensures dedicated equipment in perfect condition is always available to the customer. Agreements are established based on each customer’s needs. Agreements are powerful risk management tools, with known annual costs.

A lighter exchange unit service is available for multiple equipment and assemblies – for example, for bearing units, adjusting assemblies or complete refiners.

Read more about Valmet Refiner Exchange Service.

Read more about Valmet Exchange Agreement.

Close to you through workshop service centers around the world

Our global network of workshop service centers is available in over 14 locations around the world. In addition, there are Valmet process industry professionals in over 120 locations worldwide, and Valmet’s network of experts is available remotely with a quick response time. To reap the best benefits from these experts, you can make them part of your team through service agreements.

Related pages

Want to talk to our experts?

Please answer the below questions first. One of our experts will be pleased to contact you.