Valve controller energy saving calculator

Estimate your energy savings based on the type of valve controller

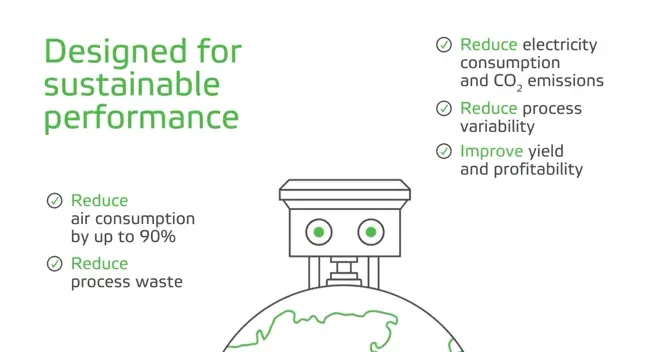

The thousands of valves that control and safeguard today’s process plant operations consume a sizeable amount of compressed air, an essential industrial utility provided by motor-driven compressed air systems that are themselves large consumers of electricity and sources of indirect CO₂ emissions. For plants relying on equipment that has been in operation for well over 10 years, planning targeted at valve positioner upgrades as part of a comprehensive lifecycle and digitalization plan can generate six-figure annual energy savings and reduce the company’s carbon footprint. In certain countries, local government subsidies may even encourage investments that aim to reduce industrial sector carbon emissions.

Valmet’s next generation Neles NDX™ intelligent valve controller consumes approximately

80 to 90 % less air than conventional controllers, making it an ideal solution to help your plant reach its environmental targets. Designed with high pneumatic capacity and high reliability and durability, the Neles NDX intelligent valve controller is a versatile solution for all actuator sizes and both linear or rotary action, suitable for all operating environments and interoperable with the most common automation and asset management systems.

To help you quantify these energy savings, we are now sharing the calculator tool featured on this webpage.

This tool uses conservative indicative values that you can replace with your plant’s own positioner quantities, the precise cost of compressed air and the average CO₂ emissions per kWh consumed.

Valve controller energy saving calculator

Estimate your energy savings based on the type of valve controllerThe air consumption of Neles NE700 positioner is about the same as for Neles ND9000. Neles NP700 positioner can be replaced with Neles NDX if the control system is changed from pneumatic control to mA control.

Valmet does not collect or store the information fed into this tool, which is intended solely for your own use.

For more information on Neles NDX intelligent valve controller, please fill in the form below:

Discover more