Flow control for construction

Reliability and process performance

Cement is by nature extremely abrasive substance which affects all parts of the manufacturing process. Reliable flow control for cement handling is crucial. Valmet's abrasive-resistant Flowrox™ slurry pumps, control and shut-off valves are therefore ideal for cement industry. Proven performance of Flowrox™ valves and pumps have shown in more than 5,500 delivered products which boost the process performance in several hundred cement plants.

Reliability

Proven performance

Robustness

Common challenges in cement handling

The performance of any reliable process depends on its components. What can first seem like an affordable flow control equipment, can quickly turn into big maintenance costs and downtime. The importance of the right selection is even more apparent when it comes to very abrasive mediums such as cement powder, slurries and grinding aid chemicals.

Cement is typically abrasive and difficult to handle even at low process pressure. Abrasive particles and high velocity causes short service intervals and operational issues, especially common for conventional flow control equipment. This inevitably leads to unwanted costs and downtime.

Reliable flow control equipment for abrasive slurry handling

In the long run, it is essential for flow control equipment to be reliable and to have a low total cost of ownership throughout lifetime. This does not only reduce spare part consumption, but also significantly reduces maintenance costs and downtime. Our Flowrox heavy duty pumps and valves are built to last in harsh process conditions found in cement processes. The robust products are designed to withstand high wear caused by abrasive mediums containing particles and powders. Wearing is effectively limited to the elastomer sleeve or hose found inside pinch valves and hose pumps.

Our heavy-duty flow control products are found in various dry and wet cement processes:

- Pneumatic conveying

- Silo feed/ discharge

- Storage tanks

- Process pipelines

- Pump isolation

- Bagging

- Grinding aid dosing

- Chemical dosing duties

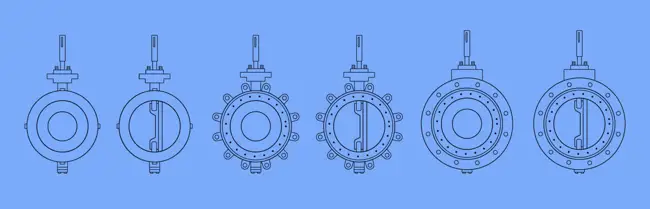

Valmet's flow control offering for cement handling