Machine Diagnostics for board and paper machines

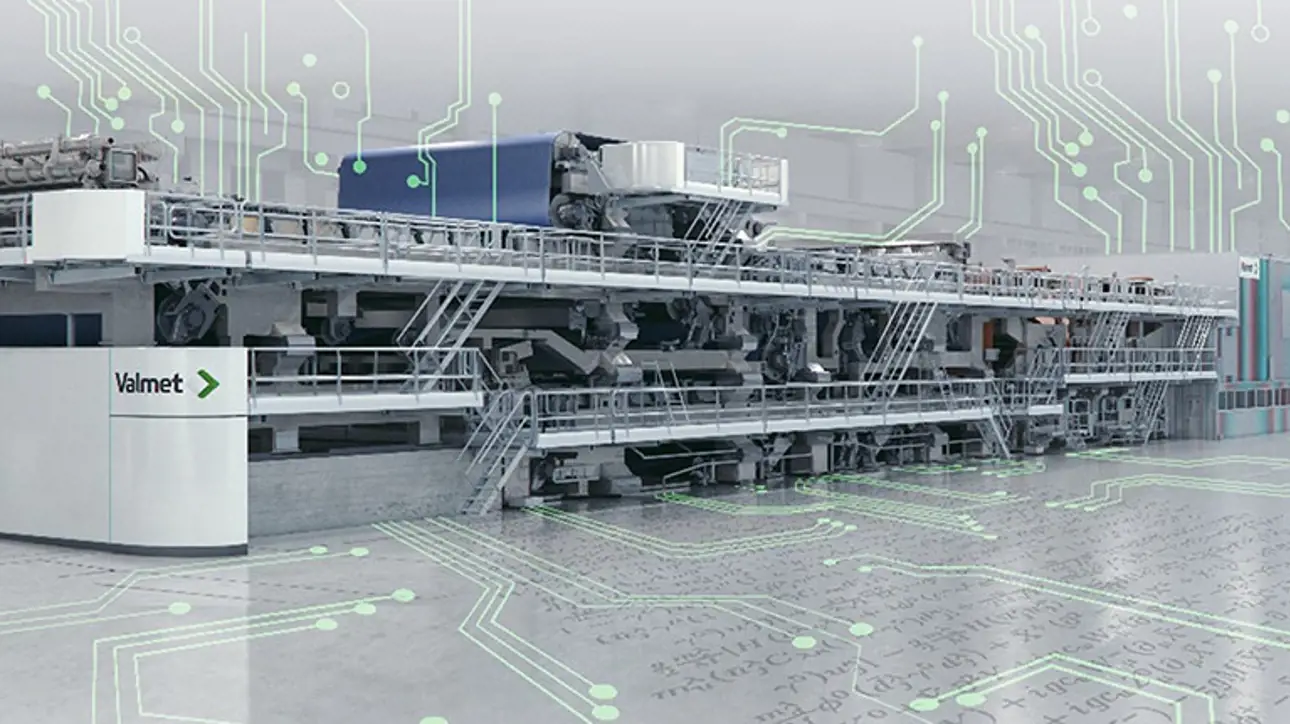

Monitoring and optimizing machine line performance with data

Valmet Machine Diagnostics give detailed insights into your entire board and paper machine line performance, with reliability agreement we collaborate to reach zero unplanned stops and improve service and maintenance predictability.

Improved service and maintenance predictability

Fewer unplanned stops

Improved performance

Data-driven service and maintenance predictability

Machine Diagnostics is a comprehensive tool for following the machine line´s performance in real time. We see immediately if any indicator gets out of the predefined range and we can suggest corrective actions to the machine operators. It means trouble-free and stable performance of the machine, less breaks and easier maintenance.

Avoid unplanned stops

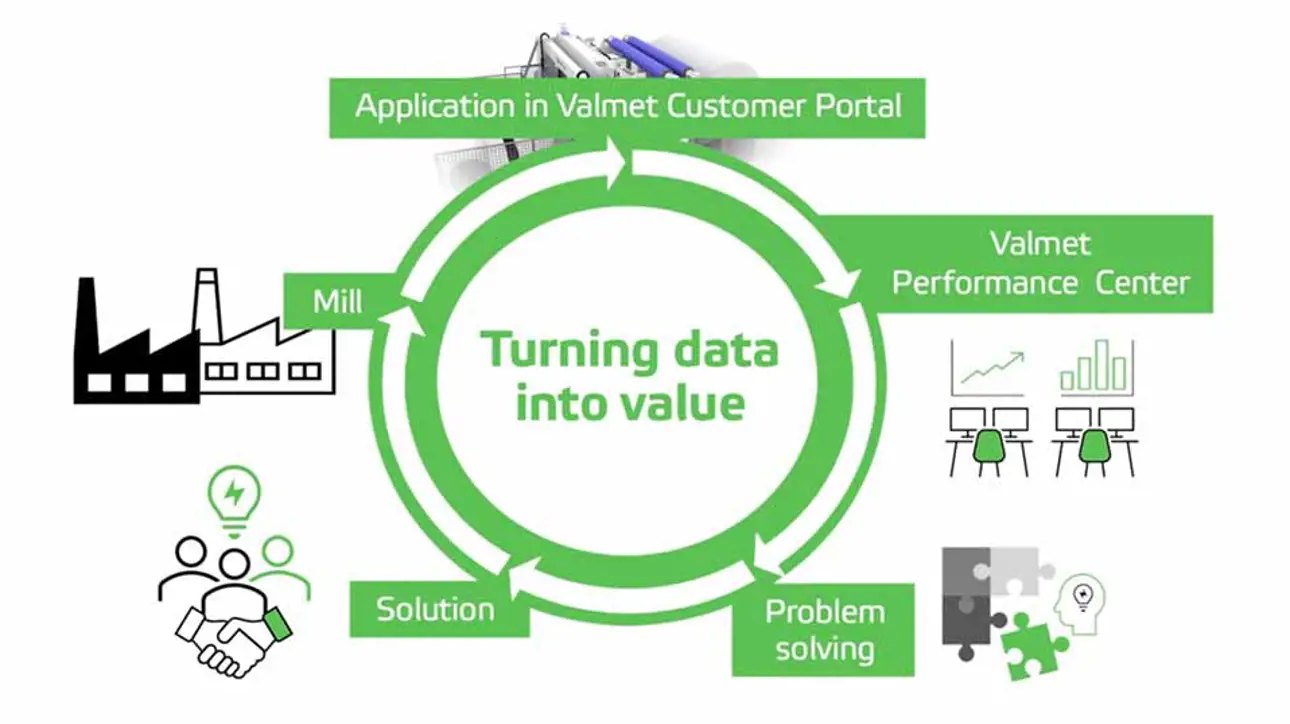

With the help of the machine diagnostics application, you can avoid unplanned shutdowns and production losses and track both small machinery failures and larger, critical ones. Greenpac Mill in USA did just this!

Read how Greenpac Mill turned data into value

Improve performance with data

By tracking the conditions of the machine in real time the machine diagnostics bring the right insights and advice at the right time, from the field to the operators and to the managers alike. When doing this the existing machine’s production potential and performance can be optimized.

Questions?

Our experts are here for you and ready to discuss your challenges. Answer a few questions and we will contact you shortly.

Contact us

Get dedicated support & service

Machine Diagnostics is remotely connected to our Valmet Performance Center. Our support specialists continually keep track of your machine performance and react to any issues immediately. They study each case and get back to you with proposed solutions, so you can take immediate action and never skip a beat in production.

Are you ready to succeed with us?

Contact us to start the discussion about machine reliability agreements

Valmet may process personal data of its current and potential customers and suppliers. This processing is described in the Customer and Supplier Privacy Notice.