Valmet IQ solves an eternal corrugator warping issue

Mar 26, 2024

Stable sheet quality, less waste as well as better productivity and sustainability are the benefits that Dunapack Rodina has achieved with the intelligent Valmet IQ Warp Control system. By automatically controlling IQ Moisturizer and preheater wrap arms, the system ensures sheet flatness 24/7, even at the edges.

With Valmet’s IQ Moisturizer system, we now have full potential to fight against the warp challenges we experienced in the past but could not control, such as S-warp and edge warp. The system is very flexible. Compared with other solutions on the market, Valmet’s system has huge advantages that are beneficial for our quality,” says Ivo Basmadzhiev, Quality Specialist at Dunapack Rodina.

For more than 60 years, Dunapack Packaging Plovdiv’s Rodina plant has been a leading producer of corrugated board and packaging in Bulgaria. It is known for its high-quality products that are mainly made of recycled paper. Its customers include leading Bulgarian and international export-oriented brand companies.

“We always aim to meet the requirements of our customers by developing our existing products further and innovating new ones,” Basmadzhiev points out.

With growing market demands, the company strives to maintain a consistently high level of its equipment and implement new technologies. “Our company’s investment policy is entirely aimed at improving the quality of our production and services. This includes renewing our production through high-quality machines from leading industry manufacturers, automation and introducing new technologies. At the same time, we want to be a role model in ensuring that our business activities contribute to a better world, a cleaner environment and a sustainable future,” he goes on.

Warp challenges caused too much waste

To boost its corrugation process, Dunapack Rodina was looking for a state-of-the-art quality control solution. The target was to eliminate the existing challenges with warping, improve quality, decrease waste and increase the productivity of both internal customers within our company and external customers.

“Our journey with Valmet started two years before we actually executed the project. A reference visit and Valmet’s system development fully convinced us of the functionality of the IQ Quality Control System for corrugators,” Basmadzhiev recalls.

In 2022, Valmet supplied a Valmet IQ Warp control system for a corrugator to Dunapack Rodina. The delivery included a Valmet IQ Moisturizer, which is the industry’s most advanced moisturizing system, and an intelligent Valmet IQ Warp Control, which automatically controls the moisturizer and preheater wrap arms to ensure sheet flatness, even on the edges.

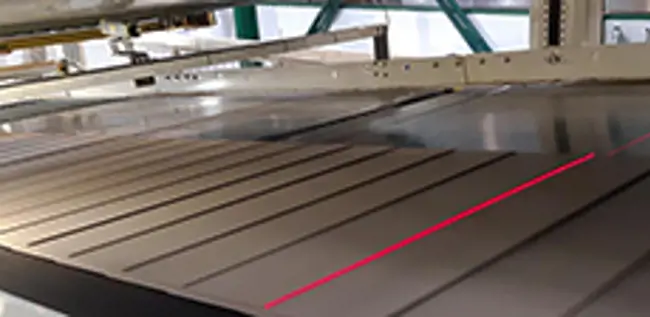

picture: Valmet IQ Moisturizer delivers warp-free production

Sophisticated quality controls are becoming more and more important. Boxes are now being made of lighter-weight board, production speeds are increasing, and production batches are smaller, resulting in more grade changes for a corrugator. The Valmet IQ Quality Control System now complements the existing temperature-based process control system. It eliminates the warp issues caused by moisture imbalances and CD profile challenges that have been impossible to correct without it.

According to Basmadzhiev, installation and startup were smooth. Both parties were well prepared, showed a professional attitude and shared the same goals. “We were like partners, not like a customer and a supplier. This actually made the project successful.”

Better quality, less waste, higher sustainability

Now after running the corrugator with the new quality control system for some time, the mill is happy with its performance – and the results gained. The investment targets set by the mill have been achieved: better quality, less waste and higher productivity for internal and external customers.

Picture: corrugated board with perfect flatness

Thanks to better moisture control and sheet quality, there has been a clear drop in waste. Basmadzhiev adds:

Waste is something that we always want to decrease. At the same time, increasing the performance of the converting machines is also very important.

He goes on to mention more benefits: “Now, sustainable production and raw material savings are more important than ever. Traceability is increasing in importance as well. With the IQ system, we can easily track the production performance of different board grades and even predict the behavior of papers involved in the combinations. This actually gives us a chance to optimize our portfolio.”

Text: Marjaana Lehtinen