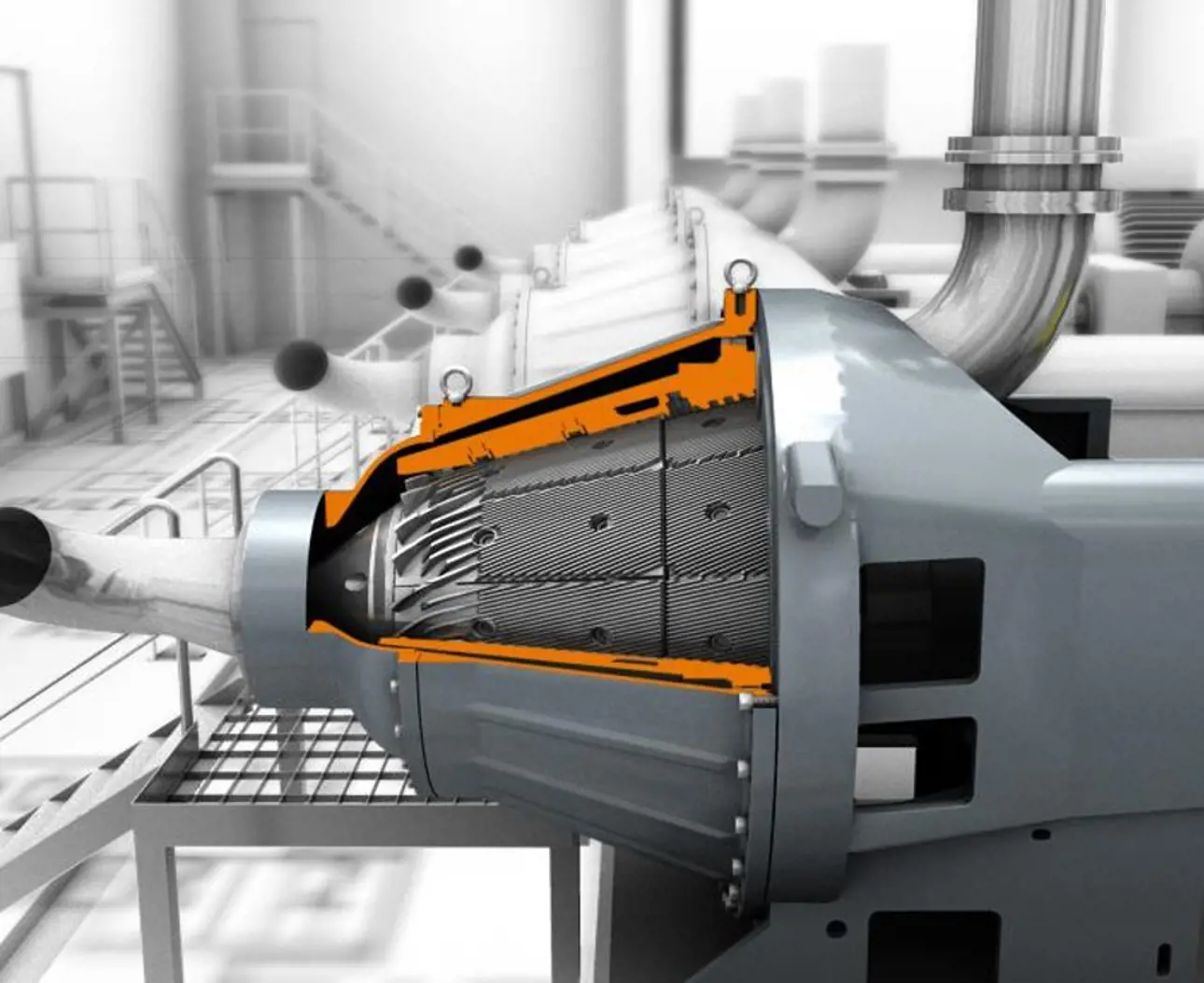

PWPW S.A. achieves 50% energy savings with Valmet Conical Refiner Conflo technology

Mar 24, 2025

PWPW S.A. (Polish Security Printing Works) has successfully upgraded its refining line with Valmet’s Conical Refiner Conflo units, achieving a 50% reduction in energy consumption.

Faced with the dual challenge of increasing refining capacity and minimizing energy consumption, PWPW S.A., one of the most modern security printing companies in Europe, embarked on a comprehensive upgrade of its refining line. When selecting a technology supplier, PWPW sought a partner with extensive experience in the paper industry and proven, highly rated solutions. Valmet was chosen for its advanced Conical Refiner Conflo technology and its flexibility in refining process. Additionally, Valmet’s ability to integrate five refiners within a limited space and its strong industry references made it the ideal choice for this project.

This project has significantly improved our refining process and energy efficiency. Thanks to Valmet’s technology and expertise, we are well-prepared for the next phase of development.

Improved paper machine runnability and quality stability

The primary objectives of the upgrade were to increase refining capacity and significantly reduce energy consumption. With the new Valmet refiners, PWPW achieved a 50% reduction in energy use while doubling the capacity of the refining line. This major improvement aligns with the company’s long-term goals for operational efficiency and sustainability.

Thanks to the increased efficiency of the refining line, the paper machine now benefits from a sufficiently large pulp buffer, allowing it to operate at maximum capacity. The stability and homogeneity of the refined pulp have improved, leading to more consistent paper quality and enhanced production reliability.

Refiner fillings designed also for cotton fibers

With a production process that requires the use of different types of fiber raw materials, the selection of correct types of fillings is crucial. In this field, cotton fiber deserves special attention due to its long fiber length. Accurately designed refiner fillings ensure consistent fiber shortening efficiency, achieve the required freeness levels, and maintain overall performance. Valmet specialists played a key role in this area, bringing expertise from over 200 Valmet Conical Refiner Conflo units delivered worldwide for cotton refining. With their support, PWPW selected fillings that optimize cotton refining while ensuring stability in refining performance across all fiber types.

“Valmet’s expertise was invaluable in selecting correct refiner fillings to handle our diverse fiber mix, especially cotton, which requires special treatment,” says Michał Kotynia, Tests Leader FAT/SAT from PWPW. “The current configuration is delivering the expected results, and we see further potential for optimization. I look forward to continuing our collaboration with Valmet´s Markku Partanen, Global Product Manager, Refiner segments and his team in developing this process even further.”

Michał Kotynia, Tests Leader FAT/SAT from PWPW

Seamless implementation and expert support

Despite a tight schedule, the project was completed on time and integrated seamlessly into PWPW’s broader modernization plan. Throughout the start-up phase, cooperation between PWPW´s experts and Valmet´s specialists ensured smooth commissioning and optimal performance.

“PWPW´s expertise and dedication in driving innovation made this project one we were very pleased to contribute to. Customer´s leadership and commitment to excellence have been key to our shared success, and we value the strong partnership we have built,” says Jukka Rantanen, project manager from Valmet.

All individuals and companies involved in the project (approx. 150 people in total), including domestic contractors, cooperated very effectively under the management of PWPW S.A. As a result, the project was completed precisely according to the planned schedule, with "to-the-day" accuracy.

“This achievement was made possible by the professionalism and dedication of specialists from various fields, including construction, electrics, automation, and IT systems, who contributed to this multidisciplinary project. Additionally, given the complexities of sea transport, parts delivery, and overall logistics, the project presented significant challenges. Nonetheless, the outcome achieved by the project team is undoubtedly outstanding," says Michał Kraszewski-Cąkała, Senior Project Manager at PWPW S.A., responsible for overseeing the entire project.

Michał Kraszewski-Cąkała, Senior Project Manager at PWPW S.A.

Laying the foundation for future modernization

With the new refining line’s capacity now exceeding the paper machine’s current capacity, PWPW is well-positioned for future modernization efforts. The project not only delivered immediate benefits but also created opportunities for further advancements in refining technology and process optimization.

"Cooperation with Valmet was professional and efficient at every stage of the project," says Kraszewski-Cąkała. “Special thanks to commissioning engineer Markku Karvonen and project manager Jukka Rantanen for their expertise and commitment."

“This project has significantly improved our refining process and energy efficiency. Thanks to Valmet’s technology and expertise, we are well-prepared for the next phase of development,” Kotynia concludes.

Read more about Valmet´s refiner technologies