Spare parts for Flowrox™ valves

Your reliable partner

We manufacture and deliver high-quality spare parts for all Flowrox™ valves. Genuine parts ensure that they are certified and specifically suited for your process.

Main spare parts for valves are rubber sleeves. Elastic sleeve is the core of the Flowrox valve. It is the only part in contact with the process medium. Maintenance is easy as sleeve change requires no special tools. Technologically advanced Flowrox rubber sleeves guarantee high wear and corrosion resistance, a trouble-free operation, and extended lifetime. Our sleeves are 100% tight. Standard Flowrox PV, PVE and PVG sleeves are equipped with opening tags to ensure full valve opening in all process conditions.

- Fast delivery and availability 24/7 for contract customers

- Various material choices according to end-use applications

- High quality

Sleeve: robust heart of the pinch valve

Technologically advanced Flowrox sleeves guarantee high wear resistance, corrosion resistance, a trouble-free operation, and extended lifetime. Our sleeves are 100% tight.

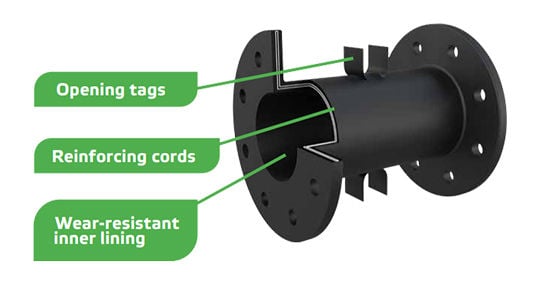

Flowrox rubber sleeves are handmade layer by layer in a quality process covered by ISO 9001:2015 and ISO 14001:2015. Sleeve has a reinforced construction, making them the pressure retaining part of the valve. Standard Flowrox PV, PVE and PVG sleeves are equipped with opening tags to ensure full valve opening in all process conditions.

Several sleeve design options including a conical sleeve for control valves and a vacuum sleeve for negative pressure applications are available. Maintenance is easy as sleeve change requires no special tools.

Read more about how to select the sleeve for a pinch valve?

The standard sleeve design consists of three sets of layers: the inner layer, the reinforcement layer and the outer layer.

Special sleeve design options include:

- Conical sleeve for control valves

- Suction (vacuum) sleeve for negative pressure applications

- Sensomate sleeve detecting and signalling critical wear

- Polyurethane lined sleeve with improved protection against wear in abrasive control applications

- FDA requirements fulfilling food quality rubbers with white inner lining

- Elastic and soft NR sleeve for very abrasive control applications

To cover a wide range of applications, several rubber qualities are available:

Standard sleeve options

- SBRT = Styrene butadiene Flowrox blend

- EPDM = Ethylene propylene rubber

Other sleeve options

- CR = Chloroprene rubber

- CSM = Clorosulphonated polyethylene rubber

- EPDMB = Ethylene propylene rubber Flowrox blend

- HNBR = Hydrogenated nitrile rubber

- IIR = Butyl rubber

- NBR = Nitrile rubber

- NBRF = Nitrile rubber, food quality (white inner lining)

- NR = Natural rubber

- NRF = Natural rubber, food quality (white inner lining)

- SBRT/PU = Styrene butadiene with polyurethane inner lining

Read more about Flowrox pinch valve sleeve type codes.

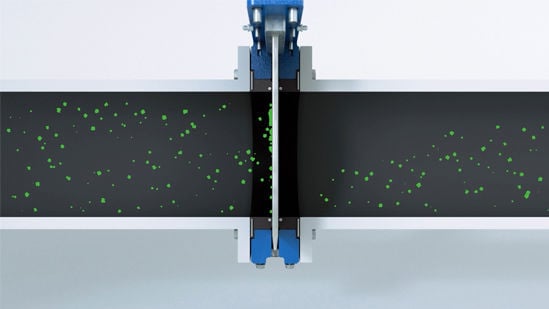

Sleeves for knife gate valves

The sleeve is a moulded part with a reinforcement steel ring integrated near the sealing area. The flange of the sleeve is reinforced with a load distribution ring to ensure even compression.

Ring sleeve material alternatives:

- NR = Natural rubber

- EPDM = Ethylene propylene rubber

- NBR = Nitrile rubber

Elastomer sleeves on both sides of the gate provide a tight shut off.

Related valve products