High-Premium tissue quality with less environmental impact

Advantage QRT Technology

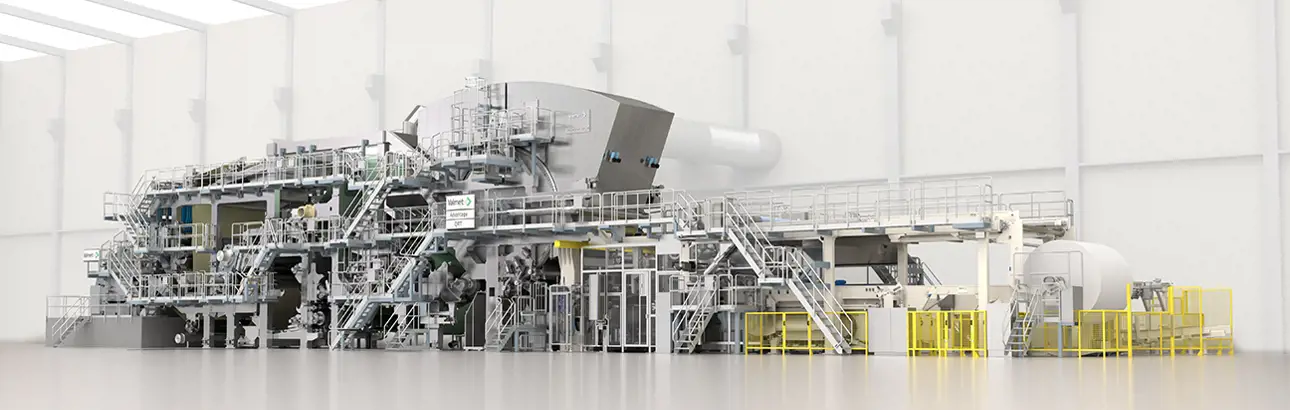

Valmet's Advantage™ QRT® technology, available world-wide meets the increasing market demands of products with high bulk, water absorption and softness. It also provides an easy and flexible production with a sustainable process and the lowest energy consumption in the world of structured tissue.

FLEXIBILITY

Unlimited possibilities for product variations

Fast change from fine and no rush to structured tissue

QUALITY

Close to TAD paper quality

Sustainable for all markets globally

SAVINGS

Significant fiber savings at half of the energy

Best cost-benefit and efficiency

A unique technology to meet the market demand

The demand for products with high absorption, bulk and softness combined with a sustainable process and low energy consumption is an increasing market trend. Valmet is therefore proud to offer a unique technology, the Advantage QRT, to customers who are looking to produce high quality products, or in a cost-efficient way wish to enter new market segments. But without compromising on their sustainability promises.

Developing products through pilot trials

The Advantage QRT process is available for pilot trials at the Valmet Tissue Technology Center. We are offering the possibility to either visit us in Karlstad, Sweden or do the pilot trial remotely. Follow the activities in the trials through live streaming cameras broadcasted on a secured web page and take part of data without delay in common software tools. We provide a creative environment for developing and testing new products, improve product quality and machine performance.

Get in touchAchieving high bulk and absorbency

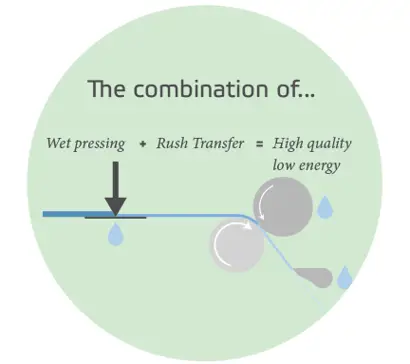

The receipt to reach the highest bulk and absorbency is normally to avoid pressing and blow hot air through the web. With the Advantage QRT technology it is possible to achieve high-premium quality utilizing pressing in combination with Rush Transfer. This means significantly lower energy consumption compared to other structured tissue processes.

The texture or structure is already done in the tissue machine at high speeds. The result will be a paper dryness up to 50% in the drying section to provide a much lower energy consumption than actual Through-Air Drying machines.

The hybrid concept can generate much higher caliper than the conventional Dry Crepe machines by using the Rush Transfer technique.

A dialogue with data to improve the performance

Valmet Industrial Internet offering covers an extensive range of solutions and applications for tissue mills in order to optimize the full scope of the production. The data driven applications and services support you throughout all the phases of the tissue machine’s lifecycle.

As a start we normally explore the potential of utilizing data through a data discovery process. Then we can evaluate what applications within production capacity, quality, energy efficiency and reliability, are beneficial for your operation. Further, our expertise is easily available for you through the Valmet Performance Centers (VPC). Our specialists have a deep understanding of machinery, processes and automation and with connections and tools, we can offer the needed remote support and guidance without delay from our 8 centers around the worlds.

Explore our VII guidebooks

What is the Industrial Internet? What do you need to know about it? And how can you make it work for you? We have prepared guidebooks to open up the most important elements of the Industrial Internet and to explain why and how data can benefit your business.

Get your guideQuestions and answers about the Valmet Advantage QRT technology

Q: What is unique with the Valmet Advantage QRT technology?

A: The Valmet Advantage QRT technology may offer advantages in improved bulk, softness, and absorbency of tissue products. The machine has an increased production efficiency, and reduced energy consumption compared to traditional methods. Valmet’s own technology utilizes a higher linear load SymBelt press to reach the sustainability claims and still provide high paper quality.

Q: Can the QRT technology produce similar products as through air drying machines?

A: By using the QRT technology tissue makers can approach the TAD product quality, but by using less energy in the production process. Around 45% less energy is used due to the amount of water that is being pressed out with the SymBelt press, resulting in water being recycled back, saving at least 40% more water compared to through air drying technique.

Q: How is the Valmet Advantage QRT technology different from conventional tissue manufacturing processes?

A: Valmet Advantage QRT technology represents a significant advancement in tissue manufacturing, offering improved product quality, efficiency, and sustainability compared to conventional processes. It adds a unique high linear load shoe press before the fabric crepe step that molds the paper into structured fabric to create high bulk and stretch, quality and different patterns.

Q: What are the benefits with Valmet’s Advantage QRT technology in terms of water, fiber and energy usage?

A: QRT enables high-quality products with less fiber consumption which can lead to cost savings and reduced environmental impact. The technology allows for lower overall water consumption per case of product due to the unique SymBelt press and Rush Transfer. Because of this, less energy is used in the drying process when comparing end-products with same geometry and much less fibers.