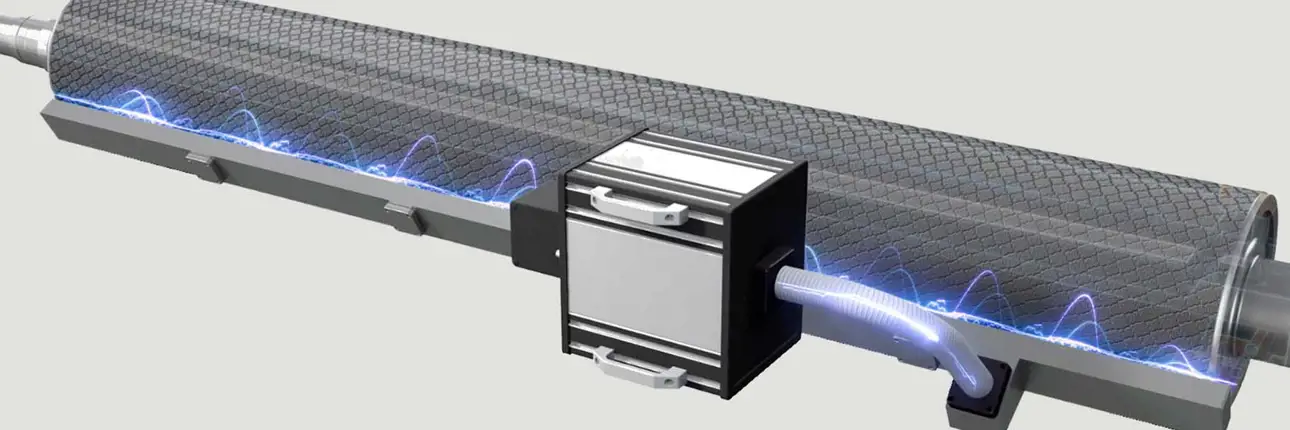

Valmet Warm-up Contactless

The world’s first system to use electromagnetic induction heating for embossing

Warm-up Contactless system is the world’s first to use electromagnetic induction heating for embossing in tissue, eliminating the need for traditional oil or water-based heating. With more than 40 units sold worldwide (Europe, Latin America and Asia), this breakthrough approach simplifies system integration and makes embossing more efficient and sustainable by reducing energy consumption by nearly 60%.

Traditional heating systems

Traditional heating systems adopting piping with either hot oil or pressurized water are more complex to install, more expensive to maintain, and more capital intensive, particularly with existing machinery as the embossing rolls must be replaced. Also, the risks associated to fire-related events for oil-based systems and high-pressure leakages for water-based systems may represent a limitation as far as safety enforcement is concerned.

Electromagnetic induction heating

Thanks to the adoption of electromagnetic induction, our patent-pending Warm-up Contactless system heats the embossing rolls from outside with no need of any physical contact with the rolls themselves, making this solution reliable a without complexity.

Warm-up Contactless Double

Warm-up Contactless is available also in the version Double for double embossed or laminated products.

Capex friendly

Our Warm-up Contactless is a plug-in system and can be retrofitted on all OEM’s embossing units already in use, without having to replace the existing rolls, which helps keep CAPEX under control.

Profitable

Reducing usage of paper for a volume increase up to 20%, our Warm-up Contactless allows for significant cost reduction of the finished products. Also, it requires virtually no maintenance compared to traditional heating systems, which results in lower OPEX.

Simple

Traditional systems adopting a heating liquid add a high degree of complexity to the line and the whole plant due to the need of dedicated areas to host piping and power heater units. Our Warm-up Contactless system is easy and quick to install with short downtime, and it doesn’t require any modification to the exisiting embossing unit.

Safe

Our Warm-up Contactless has been designed to enhance operators’ safety and eliminates any risk associated to heated oil catching fire and pressurized water leakages.

Efficient

Due to the heating principle adopted, our Warm-up Contactless shortens heating time and reduces by up to 60% the energy needed to bring the embossing rolls to the desired temperature with limited thermal dispersion - the heat is localized directly on the engraving tips and it doesn’t have to flow from the inner part of the roll - thus increasing OEE.

Flexible

Our Warm-up Contactless allows quicker changeover times – there is no need to flush the heating liquid, disconnect piping from the embossing rolls and reconnect it. This results in a wider manufacturing flexibility in terms of product mix.

Warm-up Next process

Discover Warm-up Next process: Outstanding results on finished products without using a drop of water

Read More