Advantage™ ViscoNip® Press Services

Ensure best pressing conditions for optimum capacity and product quality

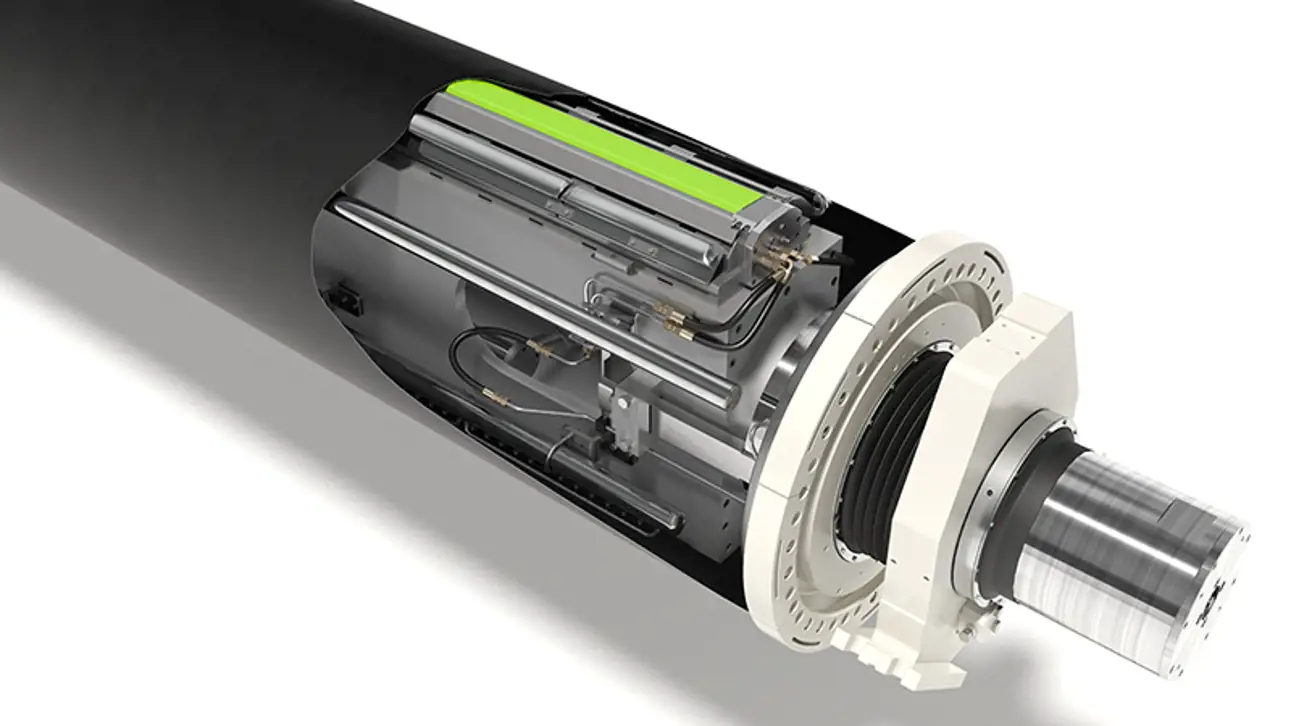

It is the new standard for wet pressing technology. A flexible liquid filled press body gives the Advantage™ ViscoNip® press the unique ability to adapt to the Yankee dryer shell. You can lower the environmental footprint in your tissue production by saving fiber, energy and reducing CO2. The amount of water removed in press section correlates directly with needed drying energy in the drying section. In comparison to a normal suction press roll it can consume up to 15% less energy and a 35% reduction in gas consumption.

Maintain the lowest possible energy consumption

Ensure best pressing conditions for optimum capacity and product quality

Access to continuous developments

Avoid unplanned shutdowns

Increase uptime and ensure cost-effective production

With a long term Advantage™ ViscoNip® press service program you can increase uptime and ensure cost-effective production. The service program includes all necessary actions to maintain your equipment in the best possible condition.

It ensures that all functions are kept fully operational. Our Advantage™ ViscoNip® service include:

- Inspection

- Recommended replacements

- Operator’s training for the most effcient implementation

Support from shutdown to production restart

During the service we will support you from shutdown to restart of the proudction. A field services expert will supervise staff of roll removal and installation, carry out complete roll service, have belt installation training with mill maintenance staff, alignment of the belt for optimal performance and stay and support you during start up.

The scope of the service actions is:

- Belt change every 9–12 months

- Pressure element exchange based on condition

- Complete hydraulic system condition test after two years, then every 4th year

- Complete overhaul every 4th year

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact usHigh speed and trouble-free running

Valmet Black Belt R shoe press belt is especially designed for tissue machines. The belt has been developed in cooperation with the Advantage™ ViscoNip® technology to perform with the highest speeds and loads on tissue machines. It survives for a long time in harsh conditions and keeps water removal at a high level.

Webinar: Preventive maintenance plan

Learn about the preventive maintenance plan Valmet has developed since starting up the first shoe press roll about 30 years ago.

Register to see a pre-recorded webinar