The critical first step when producing tissue

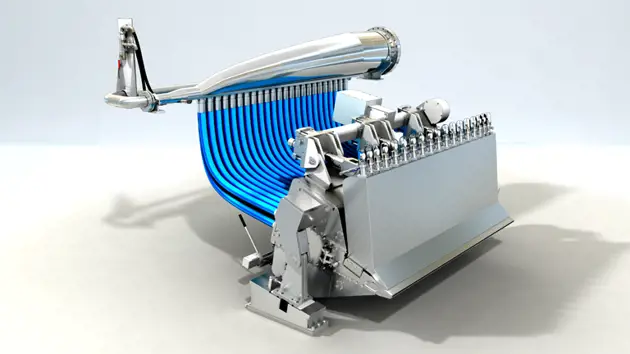

OptiFlo II TIS Headbox

Tissue making starts in the headbox. One of the most critical components on a tissue machine is the headbox. A properly functioning headbox enhances tissue makers’ ability to produce various tissue grades at the desired level of quality. The Opti-Flo® Headbox is available in different designs to suit your tissue machine.

Excellent Formation

Low energy consumption

Robust design with low maintenance cost

Even basis weight profiles

Designed for quality and productivity

The OptiFlo II TIS headbox is standard on all Valmet Advantage DCT, NTT, QRT, eTAD and ThruAir (TAD) tissue machines. A number of different models are available, each corresponding to customers’ requirements for machine widths and speeds. Each model of the OptiFlo II TIS headbox provides tissue makers with the same outstanding end-product properties. The compact and flexible design of the OptiFlo II TIS headbox makes cost-effective upgrading and rebuilding of existing tissue machines a real possibility. The OptiFlo II TIS headbox ensures the stable tissue making performance necessary for efficient tissue production.

Formation and basis weight profiles

OptiFlo II TIS headboxes are designed for optimal formation. They also show excellent layering, profiling and jet setting capabilities. In order to achieve this, we have focused on the behavior and physics of the flow of fiber in a suspension. In particular the de-flocculation and re-flocculation processes. An optimized turbulence generator and a nozzle geometry in the area before the slice creates a highly de-flocculated and uniform fiber suspension into the wire gap to enable the best possible formation.

Valmet OptiFlo II TIS solutions

| OptiFlo II TIS 1300 | OptiFlo II TIS 1800 | OptiFlo II TIS 2200 | |

| Design speed: | 1300 m/min | 1800 m/min | 2200 m/min |

| Concepts: | Advantage DCT | Advantage DCT, NTT, QRT, eTAD and ThruAir (TAD) & replacement | Advantage DCT, NTT, QRT, eTAD and ThruAir (TAD) & replacement |

| Layers: | 1 | 1-3 | 1-3 |

Low energy consumption and low production costs

An OptiFlo II TIS headbox can lower your levels of energy consumption, without sacrificing good formation and CD basis weight profiles. The design provides less floc build-ups, higher fiber concentration and in the end energy savings due to reduced flow through the headbox. This means decreased pumping energy, one of the most electric energy consuming items in the tissue mill.

Uniform formation, CD basis weight and moisture profiles, in other words, optimum uniformity of the essential properties in the tissue making process, positively impact machine runnability, efficient use of fibers, water and steam consumption and maintenance requirements. Uniformity throughout the tissue making process increases tissue makers’ possibility of hitting their production and quality targets without overcompensating for variation. Tensile efficiency saves refining energy.

OptiFlo II TIS headboxes give tissue makers the option of

high consistencies into the headbox to reduce energy

A full-scale Technology Center for pilot testing

At Valmet Technology Center we can offer the opportunity to experiment and develop tissue products and processes without having to put your own production on hold. Follow the activities in the trials on site or remotely through live streaming cameras. Pilot trials are very cost-efficient compared to expensive tests in tissue maker's own production. Naturally we work under strict confidentiality.

Book your pilot trial