Circular-based waste management plan at Valmet

We are committed to protecting the health, safety and environment (HSE) of our people, partners, suppliers, business contacts and customers, as well as the communities where we operate. We strive in all our operations towards efficient use of resources and to minimize waste and prevent pollution. We aim at maximizing the use of renewable and recycled raw materials in our technology offering by closing cycles in production processes, cascading the use of production side streams and reducing waste.

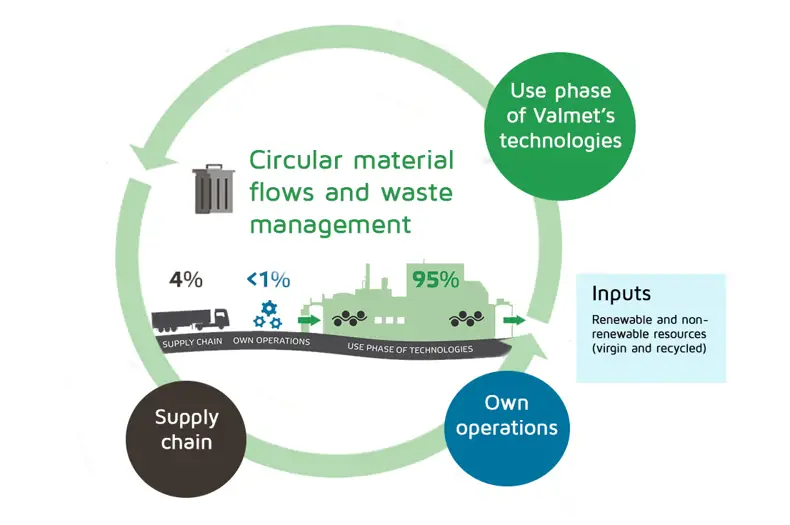

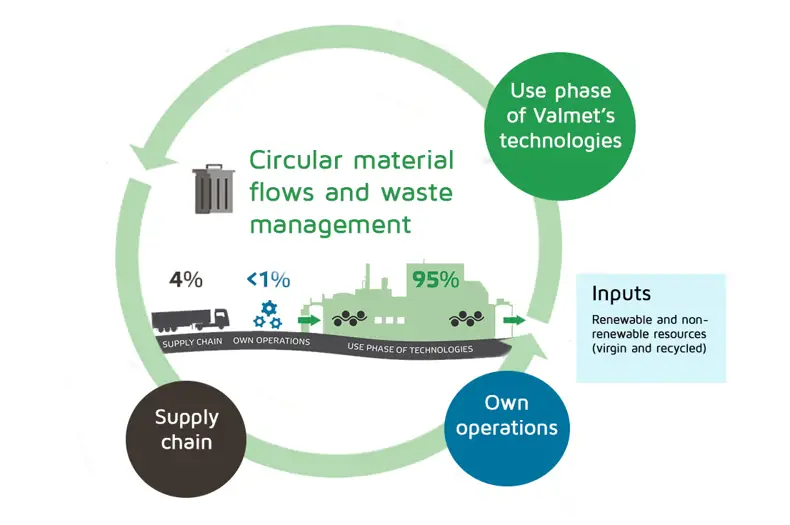

Waste flow in Valmet’s value chain

Around 95 percent of the environmental impacts of Valmet’s entire value chain, including waste impacts, occur when Valmet’s solutions are used for production on customer sites, and when our solutions reach their end of life. We design and develop all our technologies to support circular material flows and minimize waste amounts. Valmet’s process technologies, automation and services enable the circular economy for our customers.

About four percent of our environmental impact is from the supply chain, and Valmet has a systematic process for engaging with key suppliers to adopt circularity measures, identify opportunities for waste prevention and improve their waste management practices.

The remaining one percent of our environmental impact, including waste, is from our own operations.

On this image

-

1 Circular material flows and waste management

-

2 Use phase of Valmet's technologies

-

3 Supply chain

-

4 Own operations

-

5 Inputs

Circular material flows and waste management

- Resource-efficient processes

- Utilizing side streams

- Extending technology lifetime by repairing, rebuilding and converting

- Reusing, recycling and recovering waste materials

- Responsible disposal of waste through landfill and incineration

Use phase of Valmet's technologies

- Production

- Distribution

- Consumption

- End-of-life

Supply chain

- Production

- Distribution

- Site installation

Own operations

- Production units

- Service centers

- Technology centers

- Offices

- Site services

Inputs

- Metals

- Minerals

- Chemicals

- Gases

- Polymers

- Electronics

- Components

- Cardboard

- Wood

- Plastic

- Other supplies

- Energy

- Water

Effective waste management in own operations

Effective waste management is essential for minimizing environmental impacts, conserving resources, and ensuring public health by mitigating pollution and enhancing circularity.

Valmet’s procedure for waste management in its own operations aims at:

- Understanding the local operations, how waste is generated and which kind of waste streams there are

- Reducing waste

- Improving waste handling and recycling

- Improving circularity actions to reuse waste

- Compliance with environmental laws and regulations

- Meeting set targets for diversion of waste from disposal (directing waste to reuse or recycling)

- Ensuring operational control of waste (both non-hazardous and hazardous waste)

- Protecting the health and safety of employees, partners and surrounding community

Waste management is a fundamental requirement for all Valmet production locations. All locations within Valmet’s environmental reporting scope, including foundries, production facilities (manufacturing, assembly, service), technology centers, pilot plants, laboratories, supply centers , as well as offices in these locations, must implement effective waste management practices.

Location specific waste management plans

Each Valmet production location is required to define and implement a comprehensive waste management plan that outlines the methods for handling, reducing, and disposing of waste responsibly. Local employees and other workers shall be trained on the plan and their roles and responsibilities in it.

All Valmet locations must implement circular waste management practices that incorporate these global principles in local plans and operations:

- Maintain valid environmental permissions and compliance with limits for waste from operations.

- Implement waste reduction targets and actions.

- Implement the waste hierarchy.

- Map waste flows.

- Correctly categorize waste.

- Handle waste safely and sort into containers.

- Store temporary waste responsibly.

- Ensure regular waste collection.

- Use only authorized waste service suppliers.

- Monitor and report waste amounts and progress on targets.

- Be prepared for emergencies

- Report and investigate HSE events for continuous improvement.

- Train and raise awareness.

We invest continuously in process efficiency improvements, such as 3D printing, to prevent waste at its source, and we implement the waste management hierarchy in all facilities with a focus on eliminating landfill waste and reducing hazardous waste amounts. All our operations work to increase waste recycling and reuse.

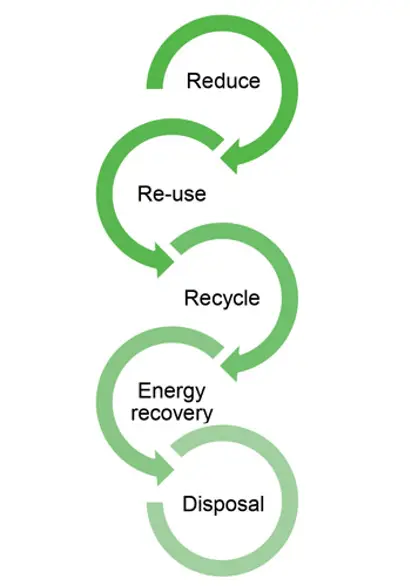

The waste hierarchy

Waste management practices shall follow the principles of the waste hierarchy, and Valmet production locations shall implement a structured approach implementing these principles.

The waste hierarchy is a structured approach to minimizing waste sent to disposal

-

Reduce - Continuous efforts to eliminate and reduce waste in the product design phase and through manufacturing process optimization. Focus also on increasing the use of non-hazardous materials and substances.

-

Re-use - Re-purposing materials and by-products for reuse within the production process or rehoming items for other uses to extend their lifecycle

-

Recycle - Collect and process waste materials into a new product to reintroduce into the production cycle, or for use in other industries, through recycling methods.

-

Energy recovery - Convert non-recyclable waste materials into usable energy such as electricity or heat, for example by anaerobic digestion or incineration with energy recovery.

-

Disposal - When all other options are exhausted, dispose of waste by landfill or incineration without energy recovery and in compliance with local regulations.

Targets and reporting on waste

To manage and improve environmental efficiency in our own operations, we have had an environmental program in place since 2009, with ambitious targets for reducing energy, water, and waste. In 2022, we updated the targets and baselines of the program to 2030.

Valmet’s target is to increase waste diverted from disposal by 75% by 2030 (2019 baseline).

Valmet measures and reports publicly waste generated, waste diverted from disposal and waste directed to disposal according to GRI standards. Valmet publicly reports % of waste diverted from disposal on valmet.com.

Multi-site certification to ISO 14001:2015

Valmet implements a multi-site global management system that is certified to the ISO 14001:2015 standard and covering majority of locations, including all foundries, production units, laboratory and pilot facilities, as well as most service workshops and supply centers, and each year we certify more locations. Currently 77% of employees work in a ISO 14001 certified location. During internal and external audits local waste management is continuously evaluated to secure implementation of global principles, local compliance and progress toward global targets.