Explore the Valmet Advantage ViscoNip Press

With a unique ability to adapt the Valmet Advantage ViscoNip press is the new standard for wet pressing technology.

TissueFilters

Explore the Valmet Advantage ViscoNip Press

With a unique ability to adapt the Valmet Advantage ViscoNip press is the new standard for wet pressing technology.

Tissue

IntelliReel

The precisely repeatable, efficient, and safe winding process

Tissue

IntelliPress

Maximize the amount of water removed from the tissue sheet while optimizing machine efficiency and product quality.

Tissue

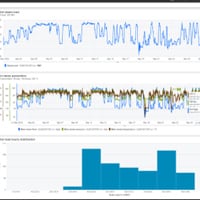

Plant Performance Monitoring

Valmet Plant Performance Monitoring is a set of dashboards that provide an overview of the performance and key parameters of your process. It can be customized to provide real-time data to the plant performance the way you need.

Energy

Pulp to Paper Optimizer

Valmet Pulp to Paper Optimizer is designed to control the properties of the paper by automatically stabilizing and optimizing the process variables to the most cost-effective level while maintaining the agreed quality.

Board and paper

Advanced process controls (APC) for Board and Paper

Maximizing process performance is a critical success factor as it directly increases profitability by increasing production capacity, lowering end product quality variations, and reducing operational costs.

Board and paper

Invest in the Valmet Advantage QRT technology for sustainable tissue production

Explore a unique technology to customers who are looking to produce high quality products, or in a cost-efficient way wish to enter new market segments. But without compromising on their sustainability promises.

Tissue

Energy R&D

Valmet's Energy R&D Center located in Tampere, Finland, focuses on fluidized bed boilers, pyrolysis, and environmental systems. Through the unique pilot facility, and its extensive experience and knowledge covering the whole energy production process, Valmet can support its customers to successfully meet the increasing demands of today and tomorrow.

Energy

Valmet ESP

Valmet Electrostatic Precipitator is a cost and energy efficient solution for removing dust particles from flue gases.

Energy

Bag House Filter

With tightening emission regulations, effective removal of dust particles and other pollutants from flue gases is a must for today’s power plants and industrial sector.

Energy