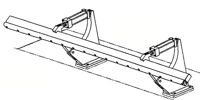

Safety when lifting, operating and servicing felt rolls

When lifting, operating and servicing the rolls, obey the OEM and mill safety instructions regarding lifting points, nips, lifting instruments and guards in order to maximize occupational safety.

Insights ● Article