Delivering reliability down the line

Oil and natural gas pipelines crisscross North America; in the US alone, approximately 150 000 km of gathering and trunklines span the ...

Insights ● ArticleFilters

Delivering reliability down the line

Oil and natural gas pipelines crisscross North America; in the US alone, approximately 150 000 km of gathering and trunklines span the ...

Insights ● Article

Common hydraulic valves – cartridge counterbalance valves

Counterbalance valves prevent oil from leaving a cylinder that is holding a load. Without them, loads would move uncontrollably if oil pressure is lost.

Insights ● Article

Flowrox valves control sludge flow in a wastewater plant without problems

Flowrox pinch valves PV 500 E01 are successfully controlling the sludge flow in a Polish wastewater plant. Twenty electrically actuated valves were delivered in 2011 to Poland through Danish engineering company Krüger A/S and local Valmet Flow Control channel partner.

Insights ● Customer story

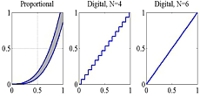

Digital hydraulic concept reduces cost and increases reliability

By using digital hydraulics, fragile and expensive proportional valves are replaced with multiple inexpensive and robust on/off valves. The results include higher reliability, lower energy usage, more accuracy in machine movements, fewer shutdowns, less lost production and lower initial investment and spare parts carrying cost.

Insights ● Article

Ready for the challenge: Valves enhance fluidised-bed polymerization

The global olefins market is expected to grow by about 4% or more in the next several years. The packaging and automobile industries are ...

Insights ● Article

Outstanding performance and zero maintenance with reliable Flowrox pinch valves

Reliable Flowrox™ high performance PVE pinch valves proved to be a perfect solution for a power generation water treatment plant located in Mpumalanga, South Africa. Six years after the installation of PVE pinch valves in power generation plant no maintenance has been required.

Insights ● Customer story

Are you in control of your polymer production?

For efficient and safe plastics production, a polymerization unit relies on numerous control and on-off valves. It’s vital to know you can count on those valves to do their job at all times. The selection of the right valve for each step requires careful consideration. And every detail matters when it comes to running a reliable, profitable plant.

Insights ● Blog post

Service is a key benefit of the product itself

Neles butterfly valves are a trusted part of many industrial processes the world over. There are currently more than a quarter of a million butterfly valves installed around the globe. And this number only includes the valves in our installed base database. In addition to the products themselves our service expertise is often a key reason behind many clients selecting our butterfly valves.

Insights ● Blog post

Reading fluids circuit diagrams - hydraulic & pneumatic symbols

Reading hydraulic and pneumatic circuit diagrams and being able to make sense out of them is a valuable skill for mill personnel. The first article in this series presents fluid control elements.

Insights ● Article

Intelligent solenoid valves: slash time and costs with knowledge

When a refinery in South America was approaching its scheduled three-year maintenance shutdown, it decided to take advantage of the information provided from its intelligent solenoid valves. Earlier, the refinery had decided to install these valves on every emergency shutdown (ESD) valve to identify degradation by using partial stroke testing (PST) for these critical valves.

Insights ● Blog post