Small decisions, big significance

Industrial gas processes are known to have high requirements on absolute gas production plant availability. Maximal availability is ...

Insights ● Article

Small decisions, big significance

Industrial gas processes are known to have high requirements on absolute gas production plant availability. Maximal availability is ...

Insights ● Article

Neles Easyflow™ resilient seated butterfly valve, series JA

Neles Easyflow JA series concentric disc resilient seated butterfly valves are suitable for a wide range of applications in manual or automated on/off through throttling control services. Although compact and lightweight, the JA series is designed to be rugged, reliable, and to comply with a variety of global industry standards.

Flow control

Valve Performance Monitoring service maximizes plant reliability at Mercer Stendal

Almost one year ago, a Valve Performance Monitoring (VPM) service agreement was signed with Mercer Stendal’s pulp mill in Germany. This 5-year (VPM) agreement covers monitoring of the most critical 500 valves, 24/7 online valve monitoring and the delivery of four expert diagnostics reports per year. Discover the customer story.

Insights ● ArticleDownload Neles Easyflow™ installation, maintenance and operating instructions

Flow control solutions including intelligent control valves and automated on-off valves, ESD valves, pumps, software, and related equipment, accessories and services.

Flow control

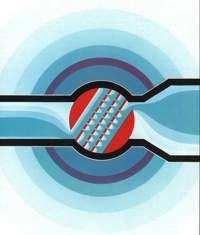

History of the Neles Q-Trim technology

One of our best-known flow control brands, Q-BALL™, has its roots in 1978 when a French “valve expert” Roger Bey presented his low noise and anti-cavitation solution developed for the ball valve to Antti Nelimarkka, the founder of Neles company (now Valmet's flow control business line). Q-BALL was the very first brand in famous Q-Trim™ technology aiming to reduce noise in control valves.

Insights ● Blog post

Machine producing unique fully recyclable barrier board is up and running in Kotka

Did you know that thanks to a Finnish innovation you can drink your coffee from a disposable cup that doesn’t have a plastic coating on its inner surface? And, after finishing your coffee, you can toss the cup into the paper recycling.

Insights ● Customer story

Metsä Group’s bioproduct mill’s process flows under control with Valmet's optimized valve solutions and services

The world’s first next-generation bioproduct mill, started up on schedule and within budget on August 15, 2017 in Äänekoski, is the biggest investment in Finnish forest industry history. Neles was selected as the main supplier of valve solutions, and the new mill has some 3,000 valves with auxiliary devices ensuring operational processes, production reliability and environmental efficiency.

Insights ● Customer story

Neles Easyflow™ one stop solution for French bioethanol producer

The French Sales team, working in close alignment with the end-user, ensured the successful delivery of Neles Easyflow solutions to a bioethanol plant in France.

Insights ● Article

OTC Brasil 2025

OTC Brasil is one of the largest global initiatives aimed at the offshore segment. Organized by the Brazilian Institute of Oil and Gas (IBP) and the Offshore Technology Conference (OTC), the event will be held from October 28 to 30, 2025, at Expomag, in Rio de Janeiro. Valmet will be present at the event presenting its solutions in valves and valve actuomation for critical applications.

Events

Neles™ butterfly valve, series L1 and L2

Neles Neldisc series L1 and L2 triple eccentric disc valves operate both in control and shut-off applications, with close to equal percentage characteristics and superior tightness.

Flow control