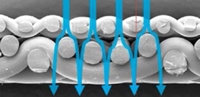

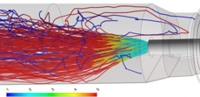

Polarized forming fabrics may revolutionize water removal

The polarized structure allows controlled initial drainage in the paper-making process, improving retention and helping keep the machine clean. The good runnability and cleanliness reduce breaks, increasing production capacity and saving through reduced use of chemicals.

Insights ● Article