Global tissue industry study

Industry leaders across 22 countries share their view on tissue making in a global market study conducted by Tietoevry, together with Fisher International, I-Plan, and Valmet.

Insights ● ArticleFilters

Global tissue industry study

Industry leaders across 22 countries share their view on tissue making in a global market study conducted by Tietoevry, together with Fisher International, I-Plan, and Valmet.

Insights ● Article

Scaling up for the future

APP is investing in a huge new paper manufacturing complex with the world’s highest production capacity, in Rudong, China. The mill aims to realize the benefits of scale by taking advantage of digitalization, future-oriented design and energy-efficient technology.

Insights ● Article

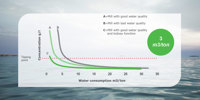

Case: What is a feasible low level of freshwater consumption?

Each mill’s water process is unique and many parameters must be considered. In this case we compare three similar mills but with different prerequisites from a water perspective.

Insights ● Article

Why Papel San Francisco continues to invest in the Valmet Advantage ViscoNip press

When Papel San Francisco last visited Valmet in Sweden we took the opportunity to ask them what role the Advantage ViscoNip press plays for their production.

Insights ● Article

Valmet changes the game in tissue

Valmet now offers the market’s widest portfolio for the entire tissue value chain, combining cutting edge technologies, services and a dynamic, technology-driven approach to tissue converting, packaging and folding equipment.

Insights ● ArticleDiscover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

On the occasion of the 2024 Valmet Tissue Innovation Days, Valmet unveils Valmet MTC Wizard, its latest cutting-edge technological advancement for Multifold products.

Insights ● Article

Power Plant Efficiency: Generating savings with flue gas condensate

The flue gas condensing is well utilized at the moment in Scandinavia with hundreds of existing condensing scrubbers. However, besides recovering heat, it’s possible to recover flue gas condensate with feasible payback-time.

Insights ● Article

Maxing fuel power to boost production

By guiding operators, the Valmet Fuel Power Maximization application enables Tampereen Sähkölaitos to unleash hidden production potential caused by varying fuel power at the Naistenlahti combined heat and power plant in Tampere, Finland.

Insights ● Article

At the core of the circular economy

Valmet’s waste-to-energy boiler (WtE) delivery to Thang Long Energy Environment Joint Stock Company will support the transition to sustainable energy and a green economy in Vietnam.

Insights ● Article

Leading the way toward carbon neutrality

Since the start-up of the Naistenlahti 3 plant, Tampereen Energia has more than halved CO2 emissions from its total energy production. The new plant is also unique since it pilots partial bed combustion, which is now available for the CFB boilers to boost flexibility in their production structure.

Insights ● Article