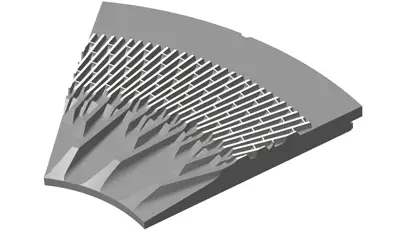

Refiner segments for medium consistency refining in pulp mills

Low-energy refining solutions for improved pulp quality and optimized refiner operations

A shorter retention time in a digester is required to obtain a higher yield in chemical pulping. This causes undissolved bundles of fibers, knots and shives which can be solved with our innovative refiner segments. With the tailored solutions, you no longer need to make sacrifices when selecting segments for your refiner. Save valuable energy, elevate refiner availability, boost production rates, extend your refiner segments' lifetime, and improve pulp quality.

Energy savings

Improved availability

Enhanced production rate

Long lifetime

Custom-made refiner segments

In the field of refining, we are continuously developing new refiner segment technologies to improve customers’ competitiveness. We offer an effective refiner segment design toolbox with patented features, experienced refiner specialists, and the most effective research and development support. Our philosophy is that every refiner is unique and needs custom-designed refiner segments.

Optimize fiber line efficiency with reduced SEC per ton - enhance production, availability, and lifetime

- Reduced SEC per Produced ton. As a supplier of refiner segments to all refiners and applications, we have the capability to optimize the fiber line for achieving even greater yield or optimized utilization of refiner's energy input. Our cutting-edge techniques enable us to process partially digested chips, thereby reducing the carbon footprint per ton of production.

- Enhanced production rate. Our innovative concept offers struggling fiber lines the opportunity to increase refiner effectiveness, thereby ensuring profitability and meeting production targets. Unlike other designs, our Refiner Segment solutions successfully overcome the challenge of simultaneously achieving high-quality output and increased production rate.

- Improved availability. Valmet Refiner Segments assist mill personnel in reducing anxiety and hassle associated with refiners by enhancing operational stability, allowing them to focus their efforts elsewhere. Our Refiner Segments provide certainty to the Fiberline and ensure overall satisfaction with the refiners.

-

Extended lifetime. Our Refiner Segments assist Chemical Pulp mills in minimizing production losses and increasing refiner availability, thereby reducing the number of stoppage days. Unlike traditional techniques, our latest feature addresses the issue of short segment lifespan by delivering enhanced utility and functionality to each refiner, effectively solving the problem.

Energy savings at a chemical pulp mill in Sweden with innovative Valmet Refiner Segments

13%

reduction in CO2 emissions

Energy savings of

150 kW

Valmet offers the widest selection of refiners and refiner segments, incorporating state-of-the-art innovations to minimize energy consumption. Let's explore how our Swedish customer achieved enhanced performance in chemical pulp production and medium consistency refining.

The term "no load" is used to describe the behavior of motors or other rotating systems under idealized conditions, where there is no external resistance. In this case, the idealized conditions refer to medium consistency (MC) of 10-15% fibers.

The implementation of optimized effective refining zone enabled our customer to achieve significant energy savings of 150 kW per refiner without affecting the production rate.

Furthermore, this resulted in a remarkable 13% reduction in CO2 emissions, contributing to a greener and more sustainable operation.

Want to know more?

Contact us to discuss more about refiners and refiner segments

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usStart the discussion about refiner segments