Wash press services for its whole lifetime

Maximal reliability and efficiency meet sustainability over wash press lifecycle

As a pulp producer, you understand the critical role of your wash press in optimizing dewatering, washing, and bleaching. Valmet’s wash press services ensure reliability, energy and cost efficiency, and enhanced production throughout the equipment's life cycle. With reliable spare parts, tailored repair solutions, troubleshooting, and process studies, Valmet combines top-tier competence with sustainability and safety.

Thanks to our long experience, we know all wash presses by heart and can offer services or technology updates that best fit the customer’s needs – regardless of the brand or the age of their wash press,” explains Murilo Vali, Global Product Manager at Valmet.

Want to talk to our experts

If you wish to get more information about wash press services and solutions, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you.

Contact usMaximal reliability and efficiency throughout your process lifecycle

- Ensure fast start-up curve and establish efficient maintenance practices for young wash presses (-2 to 5 years).

- Maintaining high productivity level for mature wash presses (5 to 20 years).

- Upgrade the competitiveness or modernize to market needs.

Real life examples from achievements with Valmet wash press services

Valmet wash press services offer a comprehensive solution for the entire lifetime of your equipment, ensuring reliable production and low, predictable operating costs. Our services focus on reducing environmental impact and supporting sustainable production practices, while providing safe and easy machine operation and usability. With stress-free maintenance and the ability to adapt to changing market needs, Valmet wash press services aim to deliver optimal performance and reliability.

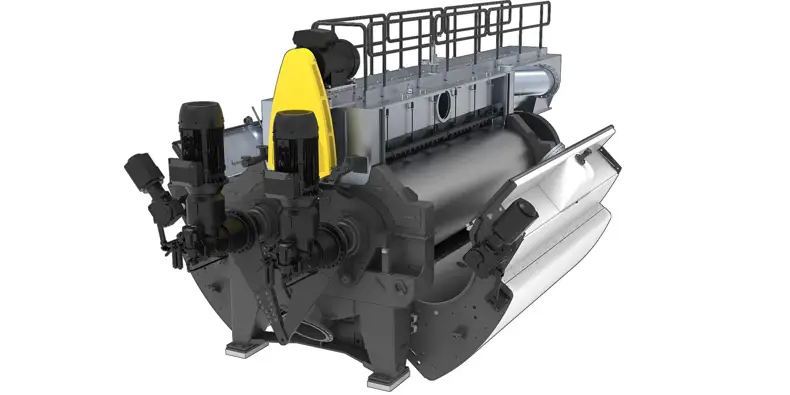

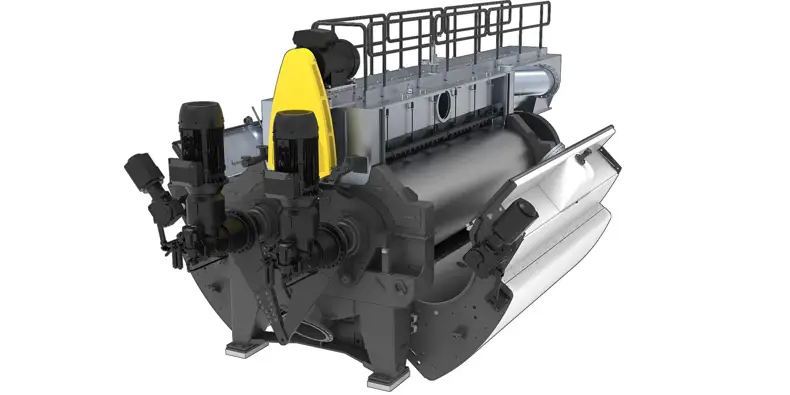

Explore our TwinRoll Press services offering

On this image

-

1 Spare Part Service Kit TRP

-

2 Performance Monitoring for TwinRoll presses

-

3 TwinRoll Press Overhaul

-

4 TwinRoll reconditioning

-

5 TwinRoll Press Vat Temperature Monitoring

-

6 TwinRoll Press Inspection

-

7 Valmet TwinRoll Press Roll

-

8 Valmet Oil Monitoring for fiber processing equipment