Bleaching of dissolving pulp

Valmet’s modern bleach plant design for PHK (prehydrolysis kraft) dissolving pulps are focused on pulp quality, efficiency and environmental friendliness.

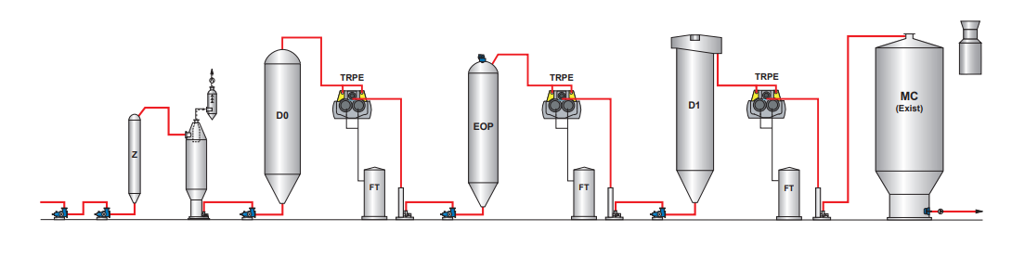

State-of-the-art bleach plant concepts for dissolving pulps are based on short ECF light bleaching sequences with an ozone stage early in the sequence. A typical dissolving pulp bleaching sequence, ZD0(EOP)D, is shown in the flowsheet below.

Valmet can also provide you with cutting-edge solutions in the field of ozone bleaching. The main reason to choose ozone bleaching when making dissolving pulp is to control the viscosity. Ozone makes it easier to control and optimize the process.

Valmet’s dissolving bleach plant design is based on the following key success design factors:

Chemical mixing

Efficient chemical mixing minimizes the consumption of bleaching chemicals and achieves efficient utilization of chemicals in each bleaching stage.

Gas mixing (of oxygen and ozone into the pulp) is specially demanding. Valmet has now launched a new generation of gas mixers for ozone and oxygen with performances exceeding all existing gas mixers on the market. Valmet’s latest generation of mixers offers an unrivalled technical solution that optimizes the input of energy and chemicals while maintaining the fiber quality.

Bleaching reactor design

Optimal reactor design is another key success factor for efficient and environmentally friendly bleaching. The aim is to accomplish a stable and homogenous plug flow of the pulp with the required retention time for each individual bleaching stage.

Barrier washing

Design principle

The main purpose of washing in the bleach plant is to provide a barrier between the different conditions in the different bleaching stages. This minimizes chemical, water, and steam consumption, as well as effluent volumes.

Stability and efficiency

The key design parameter for bleach plant washers is to control a high and stable discharge pulp consistency out from each washer. This is essential for achieving optimum conditions for the bleaching process. Excellent discharge consistency control from the barrier wash press ahead of a bleaching stage, guarantees a high and stable pulp consistency entering the chemical mixer and reactor of the bleaching stage. Barrier wash press operation will also lower chemical consumption due to an efficient barrier separation (minimum carry-over) between different bleaching stages operating with different chemicals and at different pH levels.

Sustainability

Barrier washing technology contributes to environmental sustainability since no fresh water is needed in the bleach plant and the effluent flows are lower than for other types of washing technology. Another advantage is that steam consumption can be close to zero for Valmet bleach plants.

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us