Valmet HC Ozone Bleaching

The environmental restrictions of the 1990s have led to the elimination of elemental chlorine and today’s trend is towards a totally effluent-free (TEF) bleaching process. Effective delignification prior to the pulp bleaching stages minimizes the amount of toxic effluent from bleaching. To meet those requirements, Valmet introduced new delignification and bleaching technologies. A good example of such is the Valmet HC Ozone Bleaching delignification process.

Valmet HC Ozone Bleaching combines savings with environmental responsibility

TheValmet HC Ozone Bleaching process developed by Valmet marks a clear milestone in the development of environmentally sound bleaching methods. It allows combining high brightness and strength with cost efficiency. In fiber processing, HC Ozone Bleaching represents a modern and intelligent way, in which caring for the environment is compatible with quality and production goals.

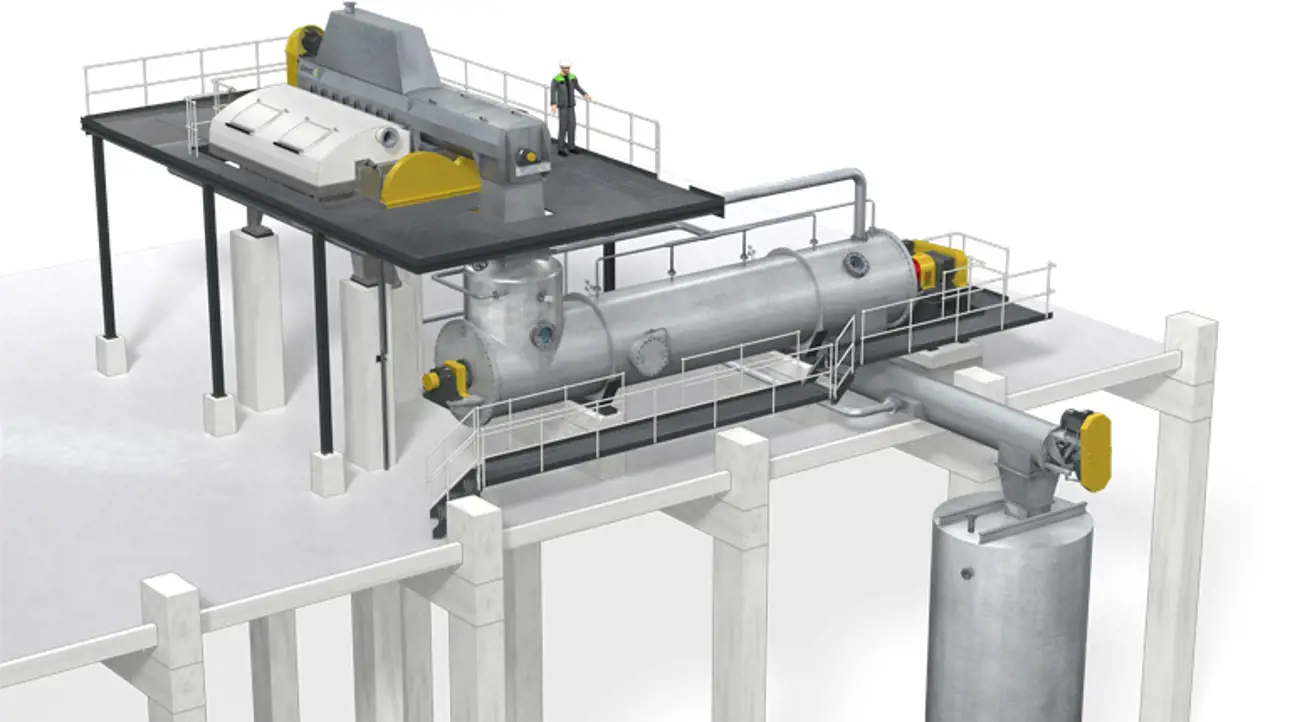

Other ozone bleaching processes on the market operate with medium-consistency pulp. In these systems, the high content of water prevents the effective use of ozone. Valmet HC Ozone Bleaching works with a high consistency of up to 40 percent. In the ozone reactor, the virtually dry fibers whirl around like flakes in a snowstorm allowing the ozone/oxygen mixture to effectively react with the fibers.

Another benefit is that the high-consistency system means that the concentration of ozone used can be low, which means lower investment costs in ozone production.

Reduces effluent discharges

Valmet HC Ozone Bleaching enables you to build a more closed system with lower effluent discharge. The system can be closed without mixing acid and alkaline washing filtrates that could lead to troublesome precipitation. Although ozone bleaching is an acidic process, there is no need for washing before alkali is added due to the high-pulp consistency.

When using ozone in mill operations, the safety aspect is of the utmost importance. The HC Ozone process has been designed in such a way that the reactor works at a slight underpressure and thus ensures that no gas can escape to the ambient air.

In today’s bleaching technology, Valmet HC Ozone Bleaching represents by far the most intelligent way to combine high brightness with care for the environment.

The first HC-ozone delignification process was brought into operation in 1992 at the Union Camp Franklin mill in the USA. Since then corresponding systems have been installed for many other customers worldwide.

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us