Innovative solutions and proven technology

HONEYCOMB ROLLS for web processing

The versatile HONEYCOMB® ROLL can handle a wide variety of webs, from wet and dry paper webs to plain and coated permeable membranes to delicate, highly permeable nonwovens, to textiles and heavy carpet.

FLEXIBILITY

Each custom-built Honeycomb Roll can be designed to suit your specific application.

INNOVATION

Uniform application of vacuum to the entire surface of the web and permits

“on the fly” adjustment to the vacuum width.

PERFORMANCE

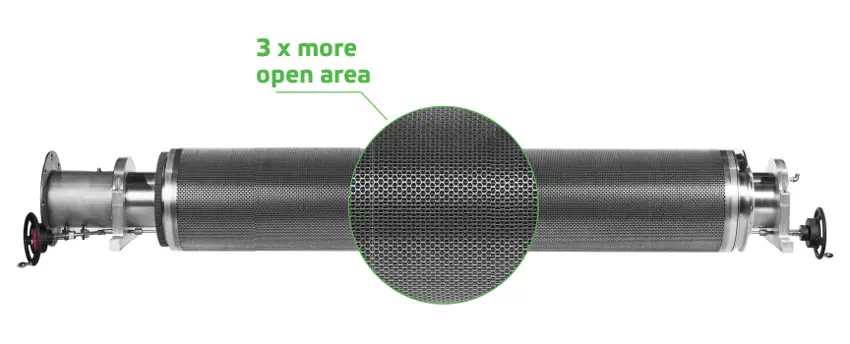

The patented, structurally rigid Honeycomb stainless steel cell gives each

roll up to 3 times more open area than conventional drilled shells.

Multiple solutions for handling continuous webs

The revolutionary design of the HONEYCOMB® ROLL creates structurally rigid cells that deliver up to 3 times more open area than conventionally drilled steel shells. Honeycomb Rolls achieve open areas of up to 96% through the roll shell. This maximizes uniform airflow throughout the web and lower energy usage.

Inspired by nature

Original inspiration for the design of Valmet’s HONEYCOMB ROLL came from the hexagonal brilliance of the honeybee's comb. This elegantly simple structure provides the mathematically optimum proportion of open air to structural integrity not only in nature, but in the manufacturing world as well.

Adjustable for accurate bonding temperature

You can adjust dwell time, temperature and through air speed to achieve maximum productivity. Unsurpassed temperature uniformity of +/-1º C (+/- 2º F) assures optimal performance from your web product, because you achieve accurate bonding temperature at each fiber junction. This allows you to improve the strength-to-basis weight ratio and take full advantage of costlier multi-component fibers.

Maximize airflow for lower energy usage

The revolutionary design of the HONEYCOMB ROLL creates structurally rigid cells that deliver up to 3 times more open area than conventionally drilled steel shells. HONEYCOMB ROLLS achieve open areas of up to 96% through the roll shell. This maximizes uniform airflow throughout the web and lower energy usage.

Processing uniformity translates into product quality

With diameters ranging from 12 inches (0.3 M) to 16 feet (4.9 M), our custom designed shell construction meets the most demanding process requirements. The benefit of using our technology is to ensure your product is processed with unfluctuating through air velocities and temperatures.

Versatility allows for variety

Besides optimum strength to open-area ratios, the other indisputable advantage of HONEYCOMB ROLL technology is versatility. It is the heart of Valmet's Thru-Air systems for drying, curing and thermobonding. We apply HONEYCOMB ROLL technology to a variety of web handling situations and the solutions they require.

-

Vacuum Tension Rolls

-

Vacuum Transfer Rolls

-

Vacuum water extraction rolls

-

Cooling Rolls

-

Forming Rolls

-

Washing Rolls

-

Porosity Measuring Rolls

-

Hydroentanglement Rolls

-

Moisturizing Rolls

Stay updated with our newsletter

Interested in learning more about our nonwovens activities, new products and industry updates? Subscribe to our newsletter today!

Subscribe