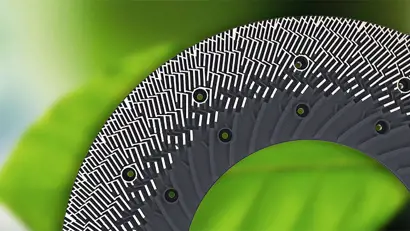

Refiner segments for MDF and fiberboard applications

Defibrate wood chips into the best possible fiber quality cost efficiently

We offer a wide range of refiner segments to optimize your plant’s performance, making the most out of the least. Our refiner segment technologies ensure the lowest possible overall costs and our approach is always individually tailored for each production line. The refiner and defibrator segment experts are continuously cooperating with our customers within for example MDF, Wet Hardboard, Doorskin, Wood fiber insulation, Molded fiber and Soil enrichment applications. They are committed to optimizing each refiner and defibrator process which often results in new refiner segment technology. Let us be your co-driver for success

Reduced energy consumption

Improved operational stability

Increased availability

Improved fiber quality

Custom-made refiner segments and experienced application experts

In the field of refining and defibration, we are continuously developing new refiner segment technology to improve customers’ competitiveness.

“We offer our customers an extensive contact network with high-skilled specialists, an effective refiner segment design toolbox with patented features and the most effective research and development support. Our philosophy is that every refiner and defibrator is unique and needs custom-designed segments.”

-Thommy Lindblom, Global Technology Manager

Solutions for your needs

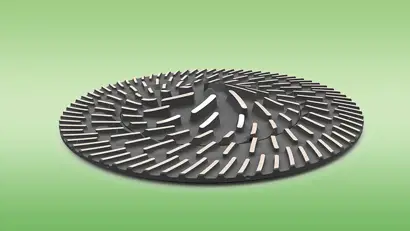

Refiner Segments - SE

Tailored multi-section solution ensuring steam and pressure balance management.

Read more here about Refiner Segments SE

Refiner Segments – Equalization lock

Patented transition feature for flow equalization and reduced steam interruption.

Read more about Refiner Segments – Equalization lock.

Refiner Segments – Uniform feed

Center part- and inlet feature for uniform chip feed both over geometry and time without steam flow disturbance.

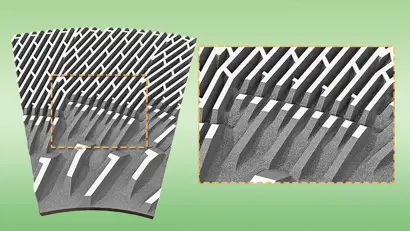

Refiner Segments - Attack bar

Inclined bars for sharper leading edges and cleaner grooves as well as energy saving over segment lifetime.

Read more about Refiner Segments - Attack bar.

Examples of other Refiner Segment features in our portfolio:

| Refiner Segments – Pitch clean | Allows steam to be evacuated from the disc gap with minimum conflict with wood flow and effectively prevent pitch build-up in the grooves. |

| Refiner Segments – Turbine | Optimized defibration through computer flow modeling. |

| Refiner Segments – Safe ventilation | Efficient steam evacuation without losing the load stability provided by the pressure peak while minimizing channeling wear of dams. |

| Refiner Segments - Vacuum flow | New generation of dams lifting the flow with minimum restriction and turbulence. |

| Refiner Segments - Vapor surf | Center part- and inlet feature for wood-steam lamination to avoid flow conflicts in chip feeding. |

| Refiner Segments - Venturi | Chip treatment through custom flow dynamics for disc gap stability. |

Refiner Segments alloys

All our segments are available in a wide range of alloys applicable for any need. Our current alloy portfolio includes more than 50 individual alloys with possibilities to customize heat- and surface treatments.

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usRelated articles

Related pages