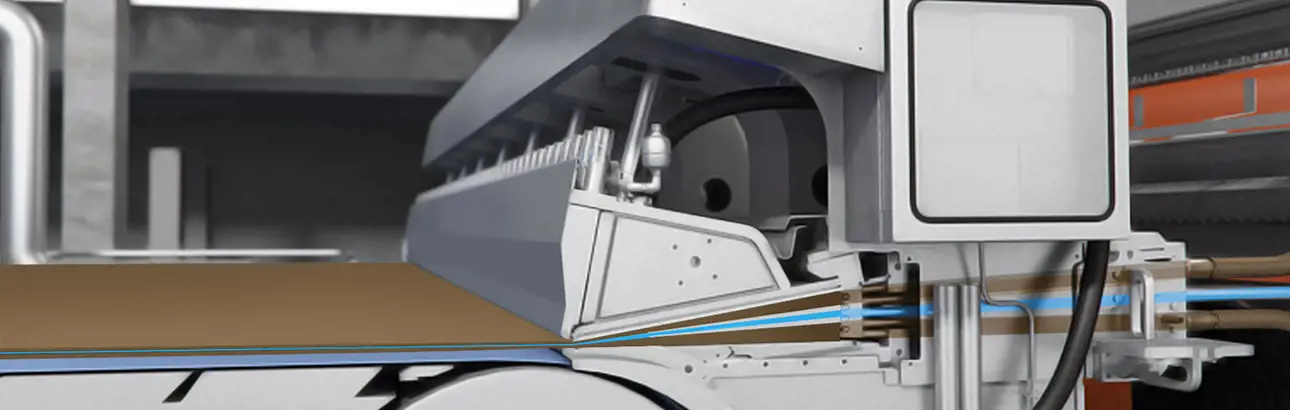

Layering headbox solutions for efficient lightweight board making

Date: December 18th, 1pm EDT, 45 minutes + Q&A

Description

During this insider session, our Valmet experts will review the fundamentals of layering headbox solutions. You will learn:

- What is a layering headbox? What does it consist of and how does it work?

- How is it different from the traditional two or three headbox concept?

- What features are unique to layering headbox solutions?

- When is a layering headbox the right solution for you?

Don’t miss out on this opportunity to gain valuable insights into the latest advancements in headbox solutions and how they can address challenges in containerboard production!

Can't make the live session? Don't worry, once you register we will send you a full high quality recording of the insider session that you can review at any time.

[NOTE: This session will be in the English language. This event is only offered to pulp, paper, board and tissue producers, P&P industry consultants and university faculty and students. Use your company or university domain email address when registering. Products and services mentioned in this presentation may not be available in all regions.]

VALMET PRESENTERS

|

|

Daniel Boren Daniel has experience in paper mills ranging from process engineer to process manager. Daniel currently works with paper machine process optimization and performance audits in Valmet. During his tenure in the paper industry, he has held positions as Process Engineer, Project Engineer/Manager, and Quality Manager. He has worked in mills for International Paper, Sonoco, and Georgia Pacific. He holds Bachelor degrees in Paper Science Engineering and Chemical Engineering from the North Carolina State University, a Bachelor’s degree in Paper Machine Technology from JAMK University of Applied Science, and a Master’s degree in Operations Management and Data Analytics from the University of Alabama.

|

|

|

Maarit Lahtinen After earning a Licentiate of Philosophy degree in organic chemistry from the University of Jyväskylä in 2000, with additional studies in paper making chemistry, Maarit has built a distinguished career in the fields of chemical engineering and board and papermaking technologies.

For 15 years, Maarit served as a Senior Scientist in the Research and Development Department at CP Kelco (currentely known as Nouryon) in Finland, where she contributed significantly to various R&D projects, in specific for example on the research and development of CMC for paints & coatings, and other industrial applications. In 2016, Maarit transitioned to Valmet Technologies in Jyväskylä, taking on the role of Senior Development Engineer in the Headbox product group. In her current position, Maarit is responsible for developing and testing novel innovative technologies and managing R&D projects related to headboxes used in paper and board production. Her work is driven by a passion for addressing customer needs and overcoming the challenges inherent in developing new technologies. |

We listened to all of the great feedback we received on enhancing our program and will now be offering Certificates of Attendance. In order to receive a Certificate, you must attend the session up until the Q&A portion.

You won't want to miss this - the Valmet Technology User Group!

Valmet Technologies Users Group is proud to present a newly expanded conference program that now includes comprehensive sessions on Wet End and Finishing processes, in addition to our traditional focus on Shoe Press and Winders technologies. This enhancement reflects our commitment to covering the entire spectrum of paper production and providing a holistic

learning and networking platform for our customers.