Valmet Sam Operational Solution provides operators with valuable virtual assistance

Precision and accuracy are imperative in toilet tissue converting.

To help manage production and operational efficiencies, complex equipment is used, including toilet tissue roll packaging machines. Manual monitoring requirements can be numerous and keeping up with the adjustments can be difficult, especially for less experienced operators. Critical points along the production line are then vulnerable to error, including in fold and packaging operations.

How can overall equipment effectiveness (OEE), product quality, and waste reduction be managed consistently and perfectly given the need and reliance on human intervention and varying degrees of operator skill?

That’s a question Valmet set out to answer with Sam Operational Solution.

Sam helps operators minimize risk, improve outcomes

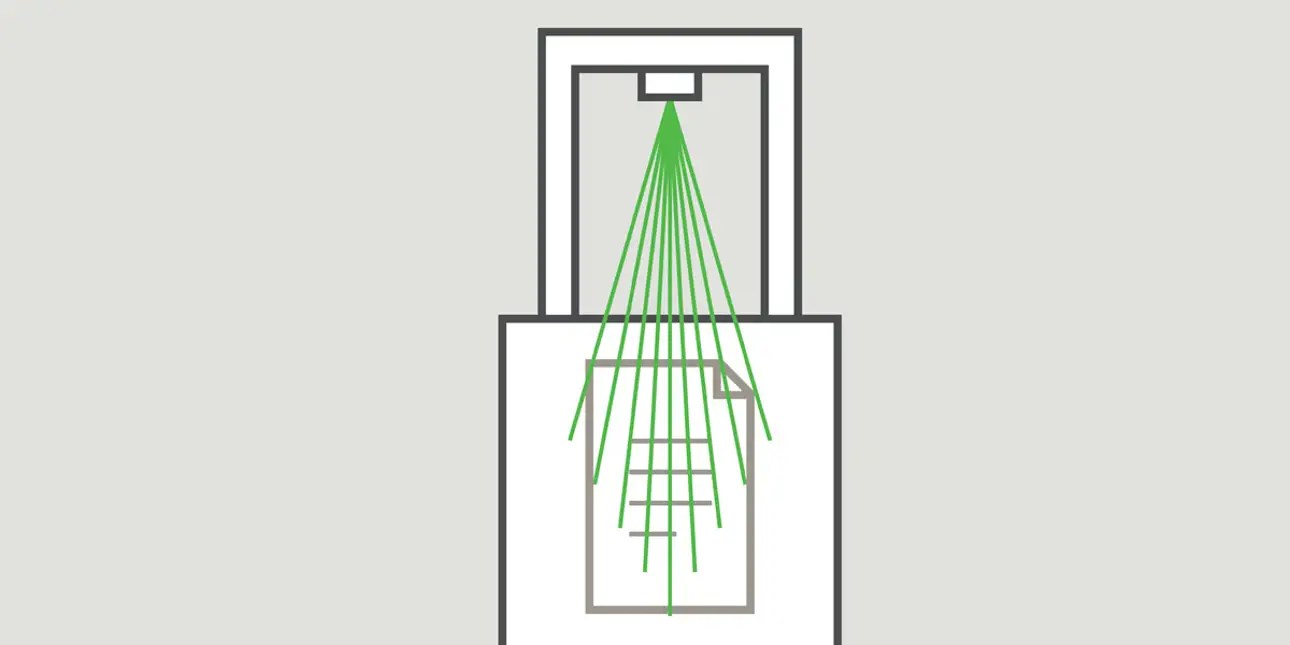

Sam is built around sophisticated sensor technology that constantly measures and monitors raw materials, finished products, and equipment performance at predetermined points where deviations likely occur.

Acting like a virtual production supervisor, Sam works alongside operators. Machine adjustments based on operator HMI input keep production parameters on track and operators safe.

Sam gives operators peace of mind because of the many benefits the technology offers. To better understand what that means, let’s look specifically at fold and packaging operations, and the alignment of Sam and toilet tissue packaging machines.

Fold: MTC Sam

- MTC Sam cut automatically checks the cutting standard, keeping the quality of each log constant sheet by sheet to detect any possible issue, without requiring line shutdown or manual pulls of sample check logs from the production line. Visual checks introduce the risk of bad cutting between logs and missed cutting between single sheets due to worn blades.

MTC Sam cut helps operators that can check the status of the blades of the rotating roll and to find if present a defective blade directly from HMI and control the blade set-up while machines are running. This means increased efficiency acting in advance by replacing or adjusting the blades performance decreases and machine downtime are prevented or avoided.

- MTC Sam reel automatically reads the main characteristics from the technical label of the parent reel and suggests the most appropriate settings for the machine, such as adjustment/control of operating data as pressure dancer rolls/load cells, percentage of paper draft on the folding head and consistency of some data of the machine recipe.

MTC Sam reel helps operators to adjust parameters increasing the machine’s efficiency. In “active” technology mode Artificial Intelligence interfaces send the information to the production line and automatically adapts the operating parameters via dedicated software.

- MTC Sam vacuum automatically manages the best amount of vacuum according to the characteristics of the paper based on the speed of the folding head and the depression set point (bar) required.

Feedback sensors also monitor inverter speed, filter clogging degree, and any issues that may arise. In the “active” version, the automatic adaption of the vacuum pump and operating parameters are set according to paper type and permeability, and process parameters. Operators have the option of using the HMI for manual settings as well.

MTC Sam vacuum helps operators balance vacuum without the guesswork, and be proactive in addressing issues, including cleaning — thereby keeping the line running efficiently and safely.

Packaging: Casmatic Sam

- Casmatic Sam cut automatically monitors packaging film perforation quality in wrapper machines. By continuously checking the interference between perforation blades, the technology is able to detect incorrect perforation in advance — avoiding jams and production downtime.

- Casmatic Sam cut helps operators identify and correct perforation issues without manually adjusting blades or having to enter the wrapper. Operator safety is enhanced, as is consistent OEE.

- Casmatic Sam pack automatically monitors primary packaging quality and handles defective packs. The HD cameras scan each side of the pack and a neural network trained by a deep learning algorithm detects any visible defect for any pack format. The non-conforming packs are then ejected.

Casmatic Sam pack helps operators leverage data to identify and pull defective packs, rather than relying on limited human capabilities. Accurate, reliable and easy to set up, the technology minimizes risk of human error and eliminates the possibility of non-compliant products getting to market.

Each Sam system measures different things at designated points on the production line, but the collective goal is the same: monitoring precision, accuracy, and quality throughout the tissue converting and packaging process. As such, these Valmet innovations act as virtual production supervisors that empower operators to do their jobs better, faster, and safer than ever before.