Neles™ Neldisc™ triple eccentric butterfly valves: The ultimate solution for control and shut-off applications

Versatility and reliability in one package

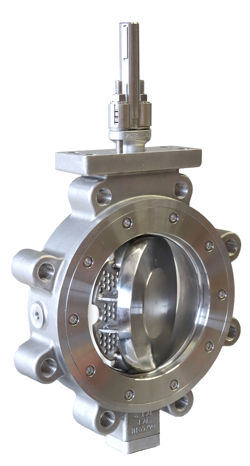

Neles Neldisc triple eccentric butterfly valves are designed for customer success. These valves excel in both control and tight shut-off applications, offering customers’ processes the perfect balance of control and tight shut-off capabilities. Their design ensures an extended operational lifespan, making them a reliable choice for control service. Available in three different body types (wafer, lug, and double flange), these butterfly valves offer adaptability to diverse environments enabling an ideal fit to customers’ application. Furthermore, a wide range of materials and seat combinations are available, covering a broad spectrum of applications and ensuring long-lasting performance with minimal maintenance. Since there is no contact between the seat and the disc in the open or intermediate positions, the most common wear points are eliminated, enabling high operational life for the butterfly valve in control service.

The triple focus: Control performance, low emissions, and Long-lasting tightness

In addition to Neles Neldisc butterfly valve’s reliability and extended operational lifespan, control performance, low fugitive emissions, and seat tightness can be considered the most important features of control valves. Control performance encompasses attributes such as repeatable performance, fine control capability and accuracy, linearity, and low friction. Low or zero fugitive emissions have become a standard requirement for butterfly valves across various applications. Seat tightness is needed to serve both on-off and control cases with the same valve type, and, for example, allow occasional tight shutoffs in the control lines.

Enhancing control valve performance

The inherent design of Neles Neldisc triple eccentric butterfly valves results in minimal mechanical friction, ensuring smooth control with superior characteristics. Moreover, essential features for control valves include fire-safe construction, wide control range, capability for cavitation and noise reduction, good serviceability, and high flow capacity. Precise controllability is achieved through a smoothly rising installed characteristic curve, accommodating very small openings as well as near-full flow capacity positions. For example, Neles™ Q-Disc™ flow balancing trim features extreme flow balancing for control service. This design also provides market-leading noise reduction. It minimizes cavitation and vibrations, leading to a longer cycle lifetime of the butterfly valve in control service.

Whole service solution with Valmet Flow Control - Maximizing value with total cost of ownership

Valmet Flow Control provides one-stop flow control solutions for the best and most reliable customer experience and optimized flow control solution selection. The whole valve with topwork assembly is provided by Valmet. Linkages to connect the valve and the actuator are designed for the whole assembly and are guaranteed to work by testing all assemblies. Intelligent positioners enable the live monitoring of valve performance and better-targeted maintenance planning with detailed diagnostics maximizing customers’ process efficiency and reliability. When maintenance is needed, the spare parts can be replaced without major disassembly, and basic maintenance work is possible on-site.

Valmet Flow Control provides customers with the most effective total cost of ownership, offering overall support from optimized solution finding to purchasing, through low energy consumption to the highest possible process efficiency, and even after years, to service and upgrading.

Read more on the topic

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe