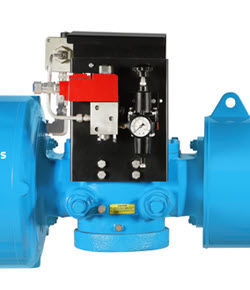

On-premises actuator configuration to your specifications

Whether you are automating your butterfly valve, ball valve, globe valve or gate valve, our modular actuator design creates a new level of flexibility. Because we stock a wide variety of parts and components centrally in Europe, we can assemble your solutions to order. This also gives us the opportunity to carry out rigorous torque bench testing at our facility before sending out your order for fast and accurate ground delivery from relatively nearby.

Thanks to the sheer number of parts and components we stock locally at the plant in Germany, the unique combinations of valve actuator configurations we can offer is exponential. With our range of actuator frames, spring modules and cylinders we can meet a huge variety of design, sizing, and torque/pressure considerations. We can meet just about any specifications your industrial end customer may have in mind with the offering we carry locally.

Unexpected last-minute changes in specs are not at all unheard of when it comes to industrial valve assemblies. The modular design and large stock of parts and components also means that we respond quickly to late changes and new specifications to ensure a timely delivery.

We always take sustainability seriously

The optimized plant layout in Germany and the advanced logistics design are not only there to make the customers’ lives easier. We look at sustainability and environmental impact as an important consideration for everything we do. We take care of deliveries and transportation by shipping small parts in bulk and providing a short trip for heavy assemblies within Europe, minimizing the environmental effects of shipping and deliveries as much as possible.

Securing a successful and sustainable future is a core part of Valmet’s values and way of doing business. In addition to looking for the smartest and least impactful transportation solutions, our production and assembly processes are also always under scrutiny. Sustainability is built in into the way our products are manufactured as well as how they perform as a part of your process.

Focus on your valve business

So, if you are an OEM or skid manufacturer in Europe on the lookout for a valve automation partner, remember that Valmet is able to engineer multiple instrumentation configurations according to customer specification and can deliver high quality with the shortest possible lead times. It is worth your time to look into our engineered valve automation solutions that are stocked, assembled, tested and shipped out of a convenient location. Leveraging our qualified experts and our decades of accumulated experience to deliver the precise configuration for your valve means you can proceed with confidence with Valmet as your partner while you remain focused on your core valve business.