Valmet’s flow control business driving customers’ business forward in the DACH area

The energy transition, digitalization, and growing competitive pressure are challenging plant operators. Now more than ever, solutions are being sought for a changing world. Valmet offers companies in the pulp, paper and cardboard, mining and metals, and chemical industries, refineries, and the energy sector the right flow control technologies and services for this development. Valmet supports them in adapting to the rapid changes in the market. The aim is “to advance our customers’ business with our market-leading expertise, products, and services,” explains Raimar Hellwig, Director & Service DACH, Valmet Flow Control business line.

The needs of companies in the various process industries are constantly evolving. “We help our customers improve their process performance and environmental efficiency and ensure a safe flow of materials,” explains Hellwig. With its specially designed flow control and automation solutions, Valmet is close to its customers, working with its team to improve their performance every day.

Better yield and profitability

For example, as a sustainable and efficient solution for industrial processes, Valmet has developed the Neles NDX™ 2.0 intelligent valve controller , which is suitable for both linear and rotary valves. The next-generation intelligent valve controller has a modular design that is easy to install, operate, maintain, and customize for specific requirements. It is designed to work with all valves and actuators – regardless of manufacturer and valve size. It is also compatible with the most common automation systems and is suitable for all operating environments.

The enormous performance of the control system and the high accuracy of Neles NDX™ 2.0 have a major impact on the quality of the process and the result. “The main benefit of accuracy is the better efficiency and profitability of the process due to reduced process differences. But just as with improving energy efficiency, improved accuracy also brings environmental benefits,” explains Nikolaj Brandt, Sales Manager DACH, Valve automation, Valmet Flow Control business line.

The intelligent Neles NDX valve controller offers numerous diagnostic functions and enables extremely low air consumption.

Fast response to changes

Another reason Neles NDX™ 2.0 scores highly in terms of sustainability is that the pneumatic relay of the positioner has been redesigned to consume around 80 to 90 percent less air than conventional positioners. “Thanks to the lower air consumption, the Neles NDX 2.0 enables significant energy savings and reduces CO₂ emissions throughout its lifecycle,” continues Brandt. This reduces the company’s carbon footprint. An important aspect for Valmet is that sustainability is at the center of its business strategy and operations.

In addition, the improved control performance of Neles NDX 2.0 with its process output helps significantly reduce process rejects. The intelligent valve controller not only enables consistent performance in long-running processes but also reacts quickly to changes in the process due to planned grade changes or other intended process adjustments. In addition to improved environmental performance, Neles NDX 2.0 also enables long-term financial benefits. “We see the Neles NDX 2.0 as a trailblazer for a more sustainable future – for all process industries,” emphasizes Brandt.

Merger leads to a perfect fit

The merger with Valmet about two years ago, when Neles became Valmet’s Flow Control business line, has proved an immediate success. A perfect match: Valmet develops and supplies process technologies, services, and automation solutions worldwide, which is complemented by flow control solutions from the former Neles. Valmet’s flow control business has more than 65 years’ experience and expertise in designing and manufacturing flow control solutions for various process industries. The extensive flow control portfolio consists of industry-leading valves, valve automation solutions, pumps, and related services under the renowned Neles™ and Neles Easyflow™, and renowned valves from the Jamesbury™ and Flowrox™ product brands. In addition valve communication and control products from Stonel™, and Valvcon™ product brands complete the portfolio. The company is becoming a one-stop shop for flow control solutions – a development that also has a positive effect on the flow control area of the DACH sector.

“We have the same customers in many areas. But we now supply them with a unique combination of competitive and reliable process technologies, services, and automation solutions globally. The offering is complemented by flow control solutions. Naturally, this results in synergy effects,” explains Hellwig. “This gives our customers a more comprehensive offering, as well as a more stable basis and security. We complement hardware with software, digitalization, and process optimization, as well as proactive and intelligent systems.”

The positive development in the DACH region can also be seen in Valmet’s investment in the expansion and extension of capacities in the service area in Leuna and Langenfeld. “We have also expanded our sales team to strengthen the organization. At the same time, we have new sales partners and distributors in all key regions who are making a positive and individual contribution to our established Valmet sales,” says Hellwig.

The metal-seated Neles™ XH ball valve has been designed to provide benefits over its entire lifecycle, not just during its active service life.

Valve automation also independent of the manufacturer

The Valmet valve automation center is strategically located in Germany. Regardless of the manufacturer or type of valve, the company offers high-quality actuators and automation components “with extremely short delivery times throughout Europe.” The automation center is designed to serve customers faster with Lean manufacturing and FAT testing capabilities.

For many valve OEMs and skid manufacturers, it is a challenge to find a valve automation solution for compatible approved products with a short delivery time – which makes the case for Valmet. “Our modular offering means that if project specifications change, we can react quickly to reconfigure the customer’s order and keep their project on schedule,” says Hellwig. Highly qualified engineers have the expertise to turn any customer specification into the best possible solution. “We focus on efficiency, quality, and reliability. We have taken these points into account by developing an intelligent modular range of technical actuator systems and predefined instrumentation.”

Short delivery times throughout Europe

When customers place an order, Valmet has a wide range of high-quality parts from its globally recognized product brands that are ready to assemble and to configure the required solutions. “The short delivery times throughout Europe make us a desirable alternative to competing solutions,” says Hellwig. The modular design, based on decades of experience in valve and actuator technology, “ensures a seamless connection between our actuators and the customer’s valves.”

As Valmet stocks a large number of parts and components centrally in Europe, solutions can be put together for the customer to order. “This also gives us the ability to perform rigorous torque testing at our factory before shipping the order overland from a relatively short distance for fast and accurate delivery.” With the large number of parts and components stocked on site at the factory in Germany, “we can offer a variety of unique combinations of valve actuator configurations.”

Everything fits at Valmet: The factory layout in Germany is optimized, and the logistics concept is also progressive. When it comes to transportation, the company makes sure that small parts are shipped in large quantities wherever possible, and that heavy assemblies are delivered via short routes within Europe to minimize the environmental impact as much as possible. There is no question that sustainability is a high priority for Valmet – in addition to the precise configuration of valves.

Digital tools for optimized processes

Digital tools are an important means of optimizing processes. They enable the collection and utilization of precise data. “The right digital tools can help significantly reduce the required planning and design time while ensuring a process that runs with the best possible valves for the task at hand,” explains Hellwig. Based on real-time data, this results in more stable flow characteristics of the process medium, which in turn leads to process efficiency and consistently predictable production quality.

And optimized data content helps improve the economic performance of maintenance work in plants. “The quality and availability of the data leads directly to savings in time and money for spare parts and maintenance.” Accurate process control data enables the effective planning of predictive maintenance, which also reduces the risk of valve failures and costly unplanned downtime. At Valmet, the customer’s own data and the valve data of each delivered project are organized and stored in the installed base database for future reference.

The Valmet customer portal is a digital platform. The portal offers prioritized service recommendations, live maintenance recommendations, and quick and easy spare parts ordering. Users can access the documentation of the Valmet products and the installed components, which helps reduce unnecessary stock levels, plan efficient shutdowns, or even shorten start-up times for new systems.

First address for renewable energies

Valmet’s flow solutions are highly regarded in the conventional industrial market. Thanks to its proven expertise in handling industrial gases such as hydrogen, oxygen, and related gases, Valmet’s Flow Control business line is a first port of call for valves in the emerging renewable energies market . With a comprehensive range of products, Valmet offers the solution required in each case. Segment, butterfly, and ball designs – to name just a few examples – cover practically all valve requirements in the energy transition, such as use in hydrogen, oxygen, e-fuels, or carbon dioxide plants. They can withstand temperatures of up to 700 °C. The valves in the Flow Control business line have proven themselves in both atmospheric pressure and pressurized electrolyzers and “offer outstanding control accuracy, safety, and reliability,” emphasizes Wolfgang Müller, Head of Renewable Energy & Industry Gases, Continental Europe, Valmet Flow Control business line.

Hydrogen, which plays an important role in the energy transition, has been used in the process industry for decades. The company’s renowned valves have proven their worth here – experience that pays off for customers, exemplified by the selection of materials to prevent the well-known hydrogen embrittlement. If the customer lacks experience, Valmet can use its knowledge of materials technology to the customer’s advantage to propose the best possible valve solution. The Valmet team can advise on the selection of suitable valves.

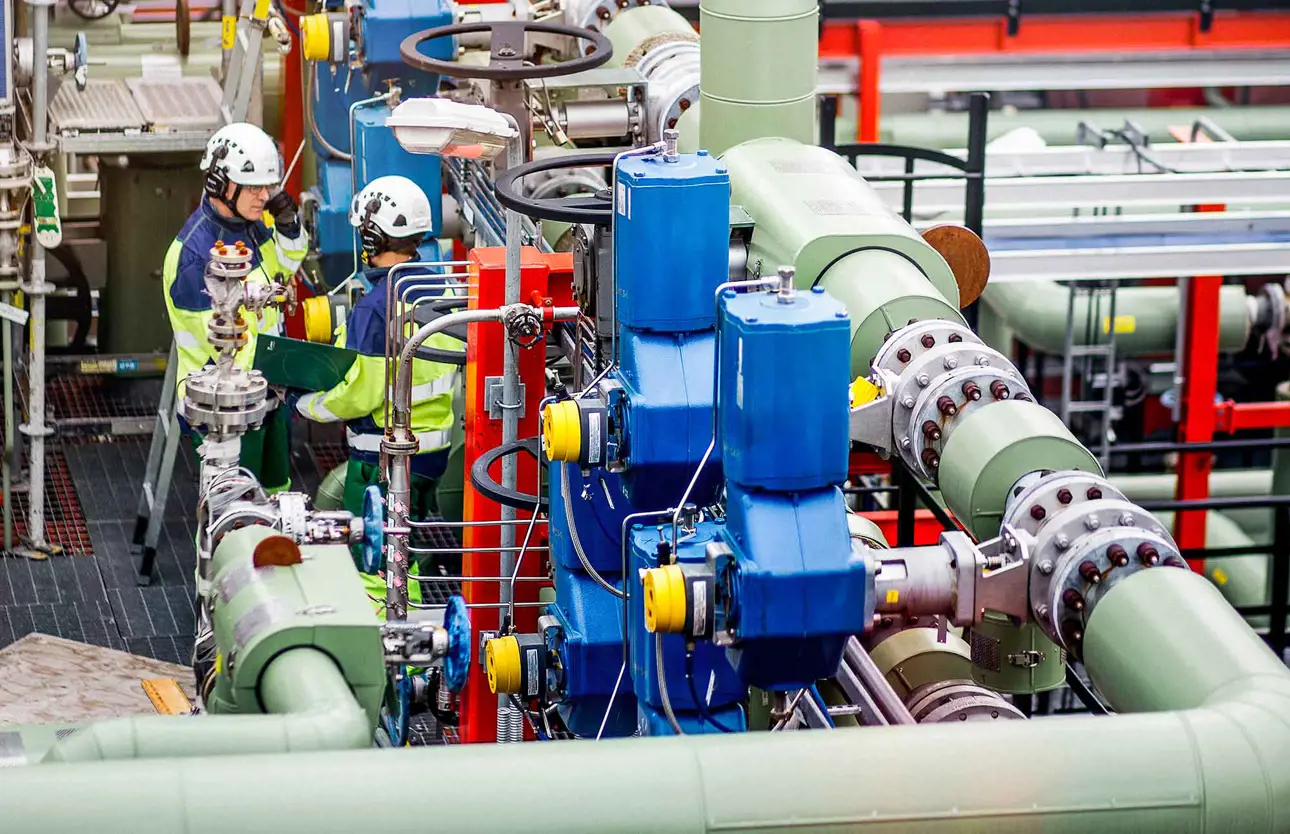

Valmet’s proven flow control solutions offer reliability for the energy transition.

Safe and effective choice for the hydrogen sector

Valmet’s flow control solutions can be found in numerous applications in the Power-to-X sector – in H₂ applications, this ranges from green electrolysis to hydrogen processes with carbon capture. Valmet’s components are used in applications ranging from the production of green hydrogen to transportation and utilization. Our decades of experience and development in the industrial sector offer a wide range of tried and tested valves for the transformation to green technology. This is because the components are optimized for the requirements of energy conversion technologies such as electrolysis, absorption, and adsorption, as well as the further use of hydrogen, oxygen, and carbon dioxide for the production of eFuels, ammonia, or methanol.

“Customers can therefore be confident that our valves are a safe and effective choice for their hydrogen applications and their processes,” emphasizes Müller. As a reliable long-term business partner, Valmet wants to create added value for its customers’ energy transition. And here as well, the commitment of Valmet’s experts does not end with the delivery of the valve but extends over its entire service life.

With a comprehensive portfolio, Valmet has the right “flow control solution” for the vast majority of applications.

The goal is completely CO₂-neutral production

Valmet is striving to enable its customers to achieve completely CO₂-neutral production by 2030. But Valmet also sets strict standards for itself in its climate program. CO₂ emissions are to be reduced by 80 percent in the company’s own subsidiaries by 2030 and by 20 percent in the supply chain. The aim is to use as few new materials as possible and to use existing material flows for longer, minimizing waste. According to Hellwig, this can be achieved by reducing the initial need for raw materials, circulating materials longer in the process, recycling the materials used, and extending the life of production facilities through well-planned maintenance.

Valmet also actively replaces fossil fuels with renewable energy sources, purchases CO₂-free electricity and district heating, and implements energy efficiency improvements in its facilities such as the modernization of LED lighting.

Valmet therefore has high and important goals: The company wants to provide the right technology to help mitigate climate change and global warming in the transition to a carbon-neutral economy. A very worthwhile goal – for the benefit of customers, the environment, and Valmet itself.

Valmet’s flow solutions and services are in demand for numerous projects worldwide.

Text by Michael Vehreschild, KCI Publishing. The article was originally published in Armaturen Welt, September 2024 issue as ‘Im Spotlight: Valmet bietet efficiente und nachhaltige Lösungen – Das Geschäft der Kunden voranbringen’

Services for valves and pumps

Reliability is at the core of every successful process plant’s operations. It leads to higher availability, safety – and profitability. By taking a proactive approach, you can stay ahead and gain deeper understanding of your plant and equipment. Valmet helps to transform plant data into valuable information. These insights enable you making the best decisions on which valve or pump to monitor, what to repair, and what to replace.

DiscoverRead more about Flow control services