EPC projects require more than just the availability of great products

There is a lot more at play in EPC projects than just the technological solutions we have to offer. Our strength lies in fact that both the EPCs and the end customers know they can trust the valves and the people with expertise behind them. We asked Oscar Bronsveld, the Director of Global Project Sales for Valmet’s flow control offering to tell us what a successful project requires from a partner like us.

What helps make us an attractive partner for an EPC with a major project in the pipeline?

It’s so much easier to partner with someone you know you can trust, isn’t it? Our field-proven technologies already serve plants and facilities in the wide range of our core industries from refining and chemicals to mining, pulp, paper and renewable energy to name just a few. While this type of proof of performance speaks to EPCs and end customers alike, it is often the added value that we as a company, and as people, bring to the table that makes us more attractive. It has a lot to do with chemistry as well.

Of course, at the core of what we deliver to projects is the valves technologies from our full portfolio of automated on-off and control valves. Our portfolio also allows us to offer distributed control systems (DCS) and safety systems in several industry segments. This holistic approach means that our offering can provide total coverage for all these project needs. From there it is much easier to build a strong working relationship where trust is extended to both the equipment and the people involved.

You speak of Valmet as a partner rather than just a vendor. How do you see the difference?

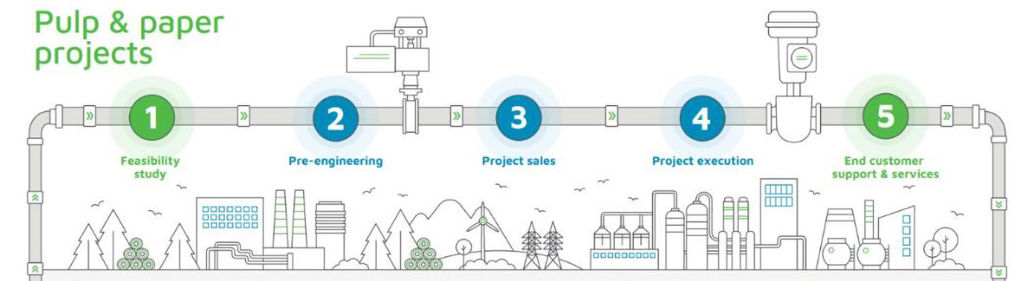

Great question. All major projects are a collaborative effort. What we want to be is a real trusted partner that also shares the goals and consequential responsibilities involved. By being easy to connect with and easy to work with, we can provide support on all levels and during all project phases. We are typically involved from the early stages of the project like feasibility and FEED till the very end when we delivery our products, and our role often also extends past the delivery, installation, and commissioning phases. There is no project without issues and challenges. In these cases it comes down to the partnership and trust where in each situation we work closely with the EPC / stakeholders to come to adequate solutions which allow the project to continue in the most optimal way. We are there when you need us. That’s the definition of a partner.

Does catering to EPC customers and large singular projects require special attention?

If you want to do it well, then in my opinion yes. At Valmet we have recognized the importance of project business, which is why we have a dedicated project organization in place. As an EPC customer you get to enjoy a single point of contact that takes on project responsibilities in the Sales as well as Execution phase. Each project has its own Valmet dedicated organization to serve & support the customer globally and locally at each location where the EPC, Package Unit Supplier and End User sites are located. At the same time, you know that there is a strong quotation team with technical, commercial and legal expertise working on your project, remotely-international or at the local Valmet offices nearest to the EPC and/or in-house at the EPC / Customer premises, whatever works best in each case. The members of our execution team also typically show up at the EPC locations with many years of experience in similar global customer projects.

Why is experience so important when we are in a vendor role in a project?

Our knowledge and experience with complex projects means that in addition to the available products we offer, we provide the selection and planning expertise that ensures that the end customer’s plant gets the best possible benefits from the valve technologies installed. Our approach is consultative and collaborative. We are committed to always trying to put ourselves in the shoes of the end customer.

Does this mean that the customer isn’t always right?

Well, the ultimate aim of the EPC is the same as ours; to deliver the best possible functioning plant as economical as possible to the end customer that has made the investment. For us this also means that we actively offer the solutions that we know can deliver the optimum performance, even challenging the customer courteously if we feel it serves a purpose.

Our strategy and approach to projects looks at the project requirements, planning, applications and the product specifications. In these types of projects what the customer wants to achieve is almost always a bigger driver than what they want to have installed. The technology as such is simply a means to the desired performance. And we understand both.

What type of projects are currently on Valmet’s radar? Where can we deliver the most value?

We are dedicated to grow and develop within our core industry focus, but in addition to that we are always on the lookout for new projects to show our full capabilities. Our approach is most suitable for those that want to scale up their processes, like the hydrogen production sector. For example, for the electrolysis process we offer not only valves, but also distributed control systems (DCS) and gas chromatography solutions. The decades of combined project expertise give us a wealth of experience that helps us anticipate issues from technical standpoint to internal policies and beyond.

We are committed problem-solvers and solution providers that work towards positive results in every case. We are not simply a product vendor, but a partner that also helps identify any arising issues and the reasons behind them, solving them as a part of the process. We are a reliable end-to-end trusted partner for any project.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe