Why should I choose a hose pump for pumping high solids concentration slurries?

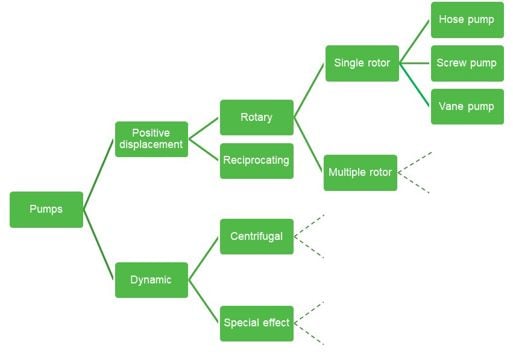

Pumps are a daily part of our lives. Various industries are said to use 10–20 percent of their total energy consumption in pumping. The task of pumps is to add energy to the fluid to make it flow, and this can be fed/added by various pump operation principles. The most common pump type is a centrifugal pump, where the impeller’s rotational kinetic energy is converted to the hydrodynamic energy of the fluid. With the hose pumps the energy is added by positive displacement effect. Hose pumps are used to pump a variety of fluids, including minerals processing slurries, while the operation principle also brings some additional advantages. We asked our pump expert Juha Häkkinen to give some tips on pump selection.

There are basically three main reasons to select hose pumps, also commonly known as peristaltic pumps. The first is the simple, and thus reliable, operation principle, which brings several advantages. The second is the hose pump’s capability of pumping high solids concentration slurries and high viscous pastes. The third is that the hose pump’s maintenance is both inexpensive and easy and fast.

Simple and reliable operation principle brings several advantages.

Flowrox™ hose pumps are positive displacement, single rolling rotor pumps, where the rubber hose is the only part that comes into contact with the medium.

Example of pump classification

The hose pumps operation principle is simple – the rolling rotor moves along the rubber hose, forcing the medium to go forward (the same peristalsis phenomenon also takes place in the human bodies in the esophagus or intestine, which is why it is called a peristaltic pump).

Operation principle of Flowrox hose pump

The operation principle brings multiple advantages. 1) Such a “pushing the medium onward” principle is very gentle to the pumped medium without any shearing, mixing or other stresses. 2) The pump’s hose has an exact volume, which is moved onward to rotation after rotation. This feature makes it accurate in dosing tasks. 3) After the compression point, the reinforced hose returns to a round shape, creating a suction effect, which means Flowrox hose pumps can be used in suction tasks without a risk of cavitation. 4) It is also worth mentioning that hose pumps don’t require any seals or seal water, running dry doesn’t harm hose pumps, and the Flowrox hose pumps can pump in both directions.

For Flowrox hose pumps, several hose materials are available for various pumped mediums: Natural Rubber (NR) for abrasive mining applications; Ethylene Propylene (EPDM) for chemicals; and Nitrile Butadiene (NBR) for oils, fats and hydrocarbons. Food-grade hoses are also available (NBRF).

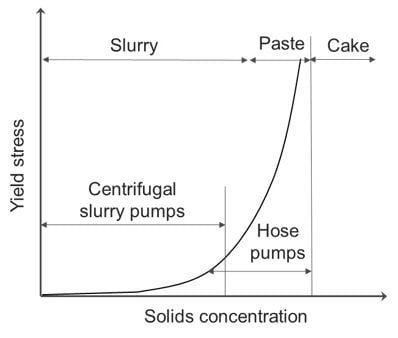

Pumping of high solids concentration slurries

In minerals processing, the actual task is to move the solid particles. For centuries, this has been done by mixing the solid particles with water and then moving the slurry by pumping. This is typically done with centrifugal slurry pumps. With higher solids concentrations (applications like high-density thickening, paste backfill, filter feed, etc.), centrifugal slurry pumps meet their operational limits, when hose pumps keep running to very high solids concentration slurries (up-to 80%w/w) and dense pastes.

Hose pumps are an excellent choice for pumping high solids concentration slurries

As mentioned above, when pumping slurries the water is acting only as carrier fluid. On the other hand, in the mining sector, water is becoming an increasingly scarce commodity. If the slurry’s solids mass concentration is increased from 35%w/w to 55%w/w, the water reduction will be 30 percent. Additionally, there will also be pump energy savings, as the same amount of solids will be pumped at a lower volumetric flowrate (less water).

Low total cost of ownership – fast maintenance.

All pump types, especially slurry pumps, require maintenance. The parts in contact with the slurry are typically replaceable wear parts. With centrifugal pumps, such parts are seals, impellers and body linings. With the hose pump, the rubber hose is the only part in contact with the medium. A spare hose is a relatively low-cost consumable spare part that can be changed on site in approximately an hour, without a need for special tools or special skills.

When selecting pumps, it is very useful to consider their lifecycle cost—not only the initial costs (perhaps only 10–20 percent in slurry pumping) but also maintenance costs, including maintenance hours and energy consumption costs. We can already provide such information about Flowrox hose pumps in the feasibility study stage.

Flowrox LPP-T transfer pumps are ideal for pumping various slurries and dosing a wide range of abrasive, corrosive, viscous or crystallizing media

Juha Häkkinen

Senior Manager, OEMs and

Slurry Flow Control,

Mining and Metals Industry

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about related products and services