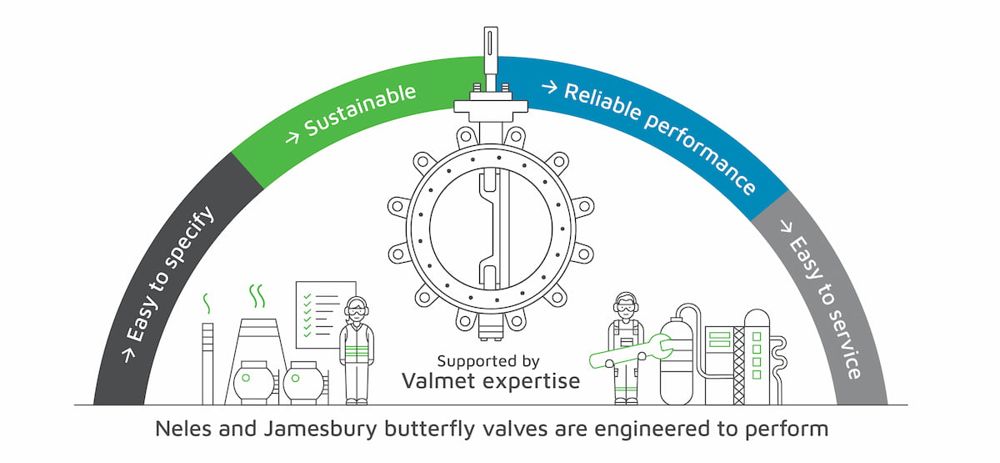

Sustainability through long-lasting efficient performance

The sustainable performance of a butterfly valve is dependent on a number of important factors. In essence, a valve that can maintain safe and efficient performance over its extended lifecycle is inherently sustainable. This means minimizing both internal and external leakages as well as the risk of failure in demanding service.

Minimizing external and internal leakages

Neles™ Neldisc™ and Jamesbury™ Wafer-Sphere™ valves are approved for both the API 607 and ISO 15848-1 certifications. This means that they have been tested and proven to provide both excellent fire safety and the lowest possible fugitive emissions. We design and manufacture all of our valves to meet the most stringent standards and regulations. Meeting these universally accepted major standards often allows for the valves to also meet many of the other local and regional standards in use around the world.

A tight seal within the valve eliminates losses and waste in terms of both flow media and the energy consumption related to pumping. These valves continuously prove their excellent tightness in operation, in both high-pressure and low-pressure applications. Both the metal-seated Neldisc and soft-seated Wafer-Sphere achieve ISO 5280 Rate A tightness and zero seat leakage as stipulated by the API 598 certification standards.

Reducing energy consumption

Energy consumption has long been one of the most recognized areas where the sustainable performance of industrial processes can be improved. One important sustainability attribute related to energy consumption and process efficiency has to do with the low torque requirement of these valves. Thanks to the unique double and triple offset valve designs much less torque is required to achieve a reliable tight seal.

The lower torque requirement directly reduces the consumption of pressured air, allowing for the use of smaller pneumatic actuators as a part of the valve assembly. By sizing down on the actuator, greater energy efficiency can be achieved in the process, not to mention the economic savings this implicates.

Extending service life

Extending the lifecycle of valves helps reduce environmental impact in several ways. Not only does it reduce the amount of material usage and the effects of valve construction, but also the environmental impact of service operations. Thanks to our design, both the sealing ring and disc are subjected to less wear during regular operations. This reduction in wear comes from the seal profile and the careful selection of sliding pairs in metal-to-metal contact.

Even valves with the most long-lasting tightness require service and maintenance from time to time. The modular construction of the Neldisc and Wafer-Sphere butterfly valves also allows for the easy service and upgrade of single components such as seats or discs, rather than replacing entire valves. Yet again, this is one more example of sustainable practices that help reduce the use of materials and resources.

The text has been updated in April 2022, due to the company name change to Valmet.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about our versatile butterfly valves