Innovative double profiling for enhanced tissue production and energy savings

Mar 12, 2025

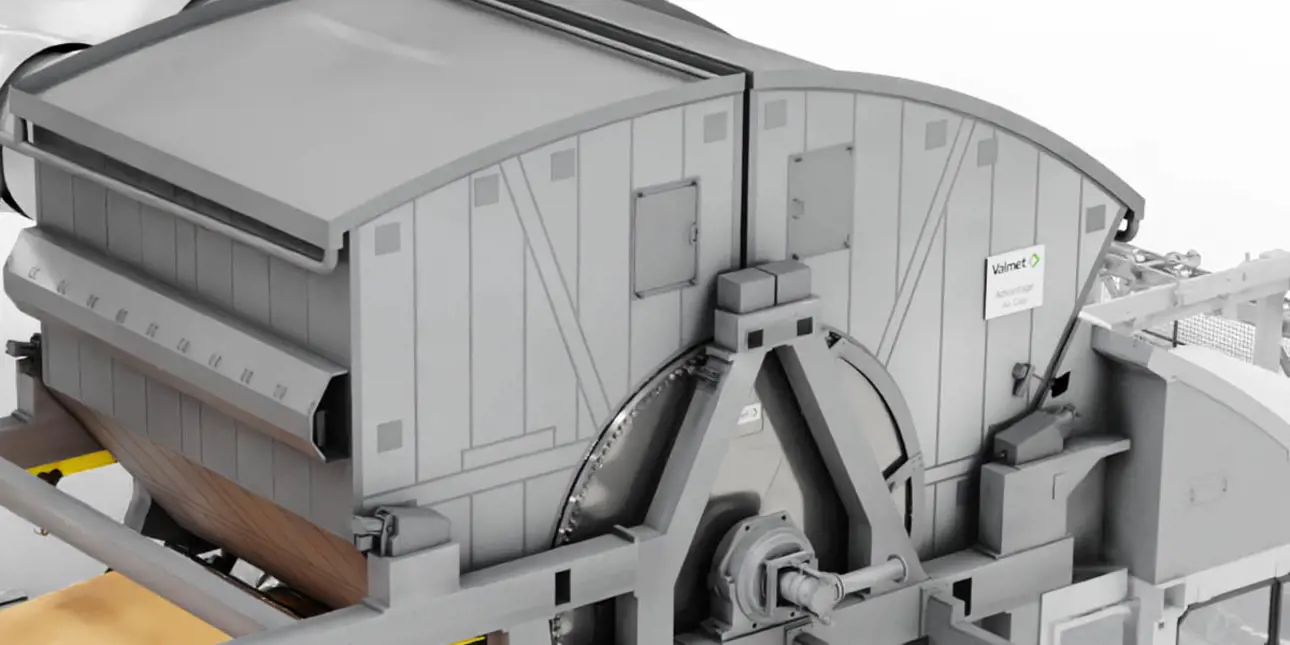

The new Valmet Advantage™ AirCap™ Pro moisture profiling system enhances tissue machine performance by adjusting air temperature and amount locally. This system balances drying intensity, resulting in a more even moisture profile and improved efficiency. It also reduces energy consumption and boosts older machines' performance.

The quality of paper produced by tissue machines and their ability to operate smoothly and efficiently at maximum speeds are significantly influenced by cross-direction profiles. Moisture profile issues are often challenging to troubleshoot and resolve definitively. Despite various efforts, some machines continue to suffer from these issues for many years.

Introducing the innovative Valmet Advantage AirCap Pro

The new Valmet Advantage™ AirCap™ Pro moisture profiling system offers a groundbreaking solution by locally adjusting the temperature of the air supplied by the hood to the paper. This innovative concept allows for increased temperature and drying intensity in areas where the paper is wetter than average, which is not possible with current profiling methods. Conversely, the system can decrease the temperature and drying intensity in areas where the paper is drier than average, resulting in a more even moisture profile at the reel.

The Advantage AirCap Pro profiles the paper by varying the temperature of the air supplied to it. In cases of very high profiling needs, it can also reduce the amount of air supplied to the paper, similar to conventional hoods. The profiling performance is double that of a conventional hood because it can vary both the air temperature and the air speed. By using higher air temperatures, the Advantage AirCap Pro can dry more where needed, which conventional hoods cannot achieve.

Integrating the Advantage AirCap Pro into older tissue machines can achieve peak-to-peak performance levels nearly equivalent to those of a new Valmet tissue machine. Additionally, it minimizes electrical energy loss through the profiling dampers and reduces burner gas consumption by lowering the average air temperature used for drying.

Moisture profiling problems can arise from several factors, including:

- Basis weight cross-direction variations

- Felt conditioning, plugging, permeability, and caliper

- Uneven press-to-cylinder linear load

- Sharp YD temperature gradients near the edges

- Uneven YD coating

- Uneven layer of condensate inside the YD

- Uneven YH impingement speed or temperature distribution

Struggling with moisture profiles

Suction pressure rolls and shoe presses often struggle to ensure even linear load and PPRC profiles under the diverse operating conditions typical of tissue machines producing a wide range of tissue grades. The crown fit between the press and the Yankee is optimized for a narrow window of machine speed, steam pressure and linear load.

Addressing the root causes of uneven moisture profiles is certainly the best approach. However, it is not always possible or easy. Therefore, it is crucial to have effective tools to correct moisture profiles when running at maximum speed and efficiency.

The shape, magnitude and spacing of the peaks in the cross-direction moisture profile significantly impact tissue quality and machine performance.

The illustration below shows typical uneven moisture profile

The costs associated with uneven moisture profiles can be significant and sometimes difficult to quantify. Tissue machine operators are often forced to over-dry the paper, adding more fibers to maintain the final desired basis weight. This process is costly, as fibers are extremely expensive, and the energy used to over-dry the paper is wasted; leading also to increased carbon dioxide emissions. Additionally, lower revenues may result from reduced machine speed and more frequent shutdowns to regrind the Yankee Dryer due to the uneven coating caused by the uneven moisture profile.

Most modern tissue machines use profiling dampers to reduce the air supplied by the Yankee Hood r to areas where the paper is drier than average, thereby increasing paper moisture. Some machines also employ a profiling steam box or both systems simultaneously.

Regardless of the method used, additional energy is required. The electrical energy wasted by the hood profiling dampers is often unknown, but could be significant for certain profiles, potentially reaching up to 45 percent of the circulation fan electrical consumption. The steam flow consumed by the steam box is more apparent and can sometimes be substantial, reaching up to 300 kg of steam per tonne of paper produced.

However, the limitation of this technique is that it does not allow for increased drying where the paper is wetter than average. The only way to achieve localized drying increase is to increase the overall drying capacity, which results in over-drying the paper and closing all other profiling dampers. This approach significantly adds to electrical and thermal energy consumption, making it a very inefficient solution.

The traditional way to control moisture profile

The new Advantage AirCap Pro moisture profiling system adjusts the temperature of the air supplied by the hood to the paper locally. This innovative concept allows for an increase in temperature and drying intensity in areas where the paper is wetter than average, which is not possible with current profiling methods.

Additionally, the new system can decrease the temperature and drying intensity in areas where the paper is drier than average. The result is a more even moisture profile at the reel.

The innovative moisture profiling system of the Advantage AirCap Pro

The Advantage AirCap Pro features two main headers: one at high temperature and one at lower temperature. Each profiling zone is equipped with a hot air profiling damper and one cold air profiling damper. The control system adjusts the opening of these dampers based on the drying needs:

- If the local average moisture is higher than the overall average, the hot air valve will open more, and the cold air damper will close more

- If the local average moisture is lower than the overall average, the hot air valve will close more, and the cold air damper will open more

Separate headers with different temperatures

The hot and cold profiling air dampers in each profiling chamber can be either mechanically linked or mechanically independent, with linkage through the control system.

The second option results in higher profiling performance compared to the first. This is because, in addition to varying the air temperature, it also allows for reducing the amount of air supplied to the paper, like the current hood profiling concept. Utilizing this feature doubles the profiling performance.

Calibration of both impingement temperature and speed

With the Advantage AirCap Pro, it is possible to achieve an even moisture profile at the reel (peak to peak 1.6%), even if the post-pressure roll consistency profile is uneven (peak to peak 2÷3%).

Even moisture profile at the reel with any post pressure roll consistency profile

Due to the double main headers with always open dampers, the electrical consumption caused by the air pressure drop through the profiling dampers is extremely low, at a maximum of 5 percent of the power absorbed by the hood circulation fan. This results in significant savings compared to today’s profiling concept.

Moreover, the Advantage AirCap Pro profiling concept offers another tangible advantage over a conventional hood: a lower thermal consumption. This is because the average air temperature supplied to the paper is lower than that of conventional hoods.

The amount of gas saved depends on the shape of the moisture profile to be corrected. The highest savings are achieved with a wet edges profile, as, in this case, the flow of higher air temperature supplied to the paper is minimized. Significant savings could also be achieved with an inclined profile. However, there would not be any substantial savings in case of a profile with dry edges, as the current profiling concept is already effective for such scenarios.

The AirCap Pro is a patented product, with Valmet holding international rights.

Remarkable savings both in case of wet edges and inclined profile

More tissue related content