Valmet reaches two significant milestones in its climate program

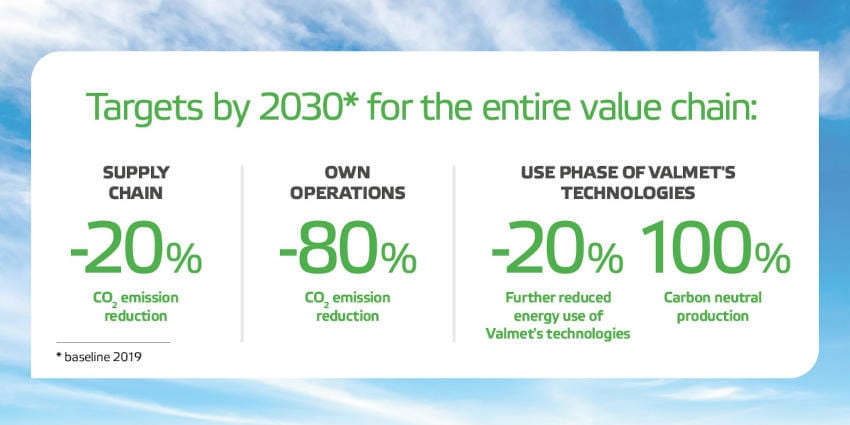

Valmet launched its climate program – Forward to a carbon neutral future – in 2021 with ambitious CO2 reduction targets across the entire value chain. During the first two years of the program implementation, we have taken many steps forward. We are especially proud of the fact that our technologies already today enable 100% carbon neutral pulp, board, paper, tissue and energy production. In addition, by the end of 2023 we will achieve 100% carbon-neutrality in our electricity purchases in Finland and Sweden.

Supply chain: Engaging suppliers to climate action

Valmet strives to reduce the CO2 emissions in its supply chain by 20 percent by 2030*. As the supplier network includes around 30,000 active suppliers in over 60 countries around the world, a significant impact on reaching the target comes from engaging the suppliers in climate action.

Valmet’s Sustainability Engagement Program has been in place since 2019, but over the past couple of years, Valmet has deepened its co-operation with selected suppliers.

“Already 75 high-emitting suppliers have committed to reducing their emissions. In addition to the extensive e-learning material we offer, our Supply Chain experts all over the world are available for hands-on support, whether it is about increasing the use of recycled raw materials or CO2 -neutral electricity, changing fossil fuel-based production systems to renewable energy or developing low-carbon logistics chains,” Jani Suomalainen, VP, Supply Chain at Valmet, says.

The CO2 intensity of Valmet’s supply chain is still on the same level as in 2021, mainly because Valmet’s purchases have further increased in the high-emission countries such as India and China. Considering logistics, however, emissions have already reduced, for example the use of air freight has reduced in 2022-2023 by better planning which has obviously reduced emissions.

Valmet has also systematically progressed with the target to increase the share of recycled steel in its products.

“Two thirds of the steel used in our foundries is already recycled and about half of the steel that our top 10 raw-material suppliers deliver to us is recycled. This is much higher than the average globally, as around 30% of all steel produced globally is created through recycling. Steel production is the big thing in our upstream supply chain when it comes to the emissions: every tonne of produced steel generates 2-7 tonnes of CO2 emissions,” Suomalainen summarizes.

A significant impact on reaching the supply chain emission reduction target comes from engaging our suppliers in climate action.

Own operations: Biggest CO2 emissions reduction impact from fuels, heating, and electricity

In its own operations, Valmet is targeting for an 80% reduction* in CO2 emissions by 2030.

“We have taken significant steps with CO2 emission reduction from fuels, heating, and electricity in our offices and production units around the world. Emissions from these areas have reduced by 34% from the baseline year 2019,” Victoria Larsson, VP, HSE at Valmet, tells.

In electricity purchases, Valmet reached a huge 40% reduction in CO2 emissions in 2022.

“Low-carbon hydroelectricity is being used in our Canada locations and in Jiading, China, and several locations in the USA and Europe are using other renewable energy for their electricity, just to name a few examples. In addition, by the end of 2023 we will achieve 100% carbon-neutrality in our electricity purchases in the Nordic countries Finland and Sweden. The impact is significant, as these countries represent 60% of Valmet’s total electricity consumption,” Larsson says.

Valmet also continuously implements energy efficiency improvements in its over 150 locations globally. In addition to larger energy efficiency investments, significant savings have been reached by simple actions such as switching to LED lights or adjusting the indoor temperatures at numerous locations.

By the end of 2023 we will achieve 100% carbon-neutrality in our electricity purchases in Finland and Sweden.

Solar panels installed in Valmet's location in Araucária, Brazil, in 2022. These panels provide about 8% of the location’s electricity.

Use phase of Valmet’s technologies: Enabling carbon neutral pulp, board, paper, tissue and energy production

Valmet targets to enable 100 percent carbon neutral production for all its pulp and paper customers by 2030 by developing new process technologies, and by improving the energy efficiency of its current offering by 20 percent. Only two years after the ambitious targets were introduced, one of them has been achieved.

“When it comes to the first target, enabling 100 percent carbon neutral production, we have had excellent progress as we already reached our goal in 2023. We now offer carbon neutral production opportunities for our pulp, paper, board, and tissue customers, with the precondition that the customer has bioenergy or carbon neutral electricity in use. Carbon neutral production can be achieved by combining the best available technologies, optimizing mill design and selecting the right automation, Industrial Internet and service solutions,” says Janne Pynnönen, VP R&D at Valmet.

“Having achieved this target, the focus currently is on the customers that Don’t have bioenergy or carbon neutral electricity in use yet. Together with those customers, we are trying to find ways to use different energy sources with different equipment and machinery. We are well prepared to do so, as Valmet has already long enabled carbon neutral heat and power production with our biomass-based energy solutions – in fact, many of our customers’ chemical pulp mills using our technologies already are bioenergy self-sufficient, promoting carbon neutral pulp production,” he continues.

“In tissue, pulp paper and board production, we have taken many actions to reduce energy use and we are developing individual technologies and machine sections that bring improvements in energy use. For example, Valmet sleeve roll is a great example of such development from the recent years. In pulp production, our focus has not only been energy efficiency but also water and raw material use that is important in more sustainable pulp production,” Pynnönen says.

Pynnönen reminds that even though Valmet has already achieved good results in enabling carbon neutral production for its customers, the work is continuously on-going.

“We will further emphasize developing the energy, water and raw material efficiency in our product portfolio and continue offering our services and automation solutions to our customers to optimize the production processes in the installed base. Co-operation is the key – many of our customers have set ambitious climate goals themselves, and Valmet has an essential role in helping them to achieve them.”

When it comes to enabling 100 percent carbon neutral production, we have had excellent progress as we already reached our goal in 2023.