An audit reveals equipment condition for maintenance planning

Do you know how your stock preparation equipment and rolls are really doing? Valmet audits provide a quick, economical and effective way to check whether your assets are performing at their best and to take action to optimize them.

The smaller the mill maintenance organizations are, the fewer eyes there are to detect emerging or hiding stock preparation equipment or roll failures. If they take place, the consequences can be costly. In the worst-case scenario, an unforeseen failure can lead to unplanned production losses.

To prevent such situations, Valmet offers one- or two-day audits to identify immediate and long-term service needs. Thanks to proactive problem-solving, you will be able to avoid unplanned shutdowns in your process. Additionally, by identifying maintenance needs early, you’ll reduce the risk of accidents and create a safer work environment. Based on an audit report by Valmet, you can plan the maintenance tasks for your shutdowns more accurately and make budgeting easier.

Valmet experts will also inform you about the latest technological innovations and improvements. And they will provide you with an upgrade proposal to improve your process performance.

So much depends on stock preparation

As long as stock preparation equipment works as expected, little attention is paid to its condition and maintenance. Its sudden poor and unreliable performance, however, has a crucial impact on the later stages in a paper or board making process.

For example, an unplanned refiner shutdown and a lack of spare parts can cause extended availability challenges and a high financial risk for the mill. Poor equipment condition often leads to stock quality variations, higher energy consumption and uneven wear of refiner segments or plates. These phenomena can deteriorate stock quality and increase maintenance costs.

In a refiner audit, Valmet’s experts update the installed base information, record the current refiner process values, identify any service and improvement needs, and inform you about upgrade possibilities and energy savings.

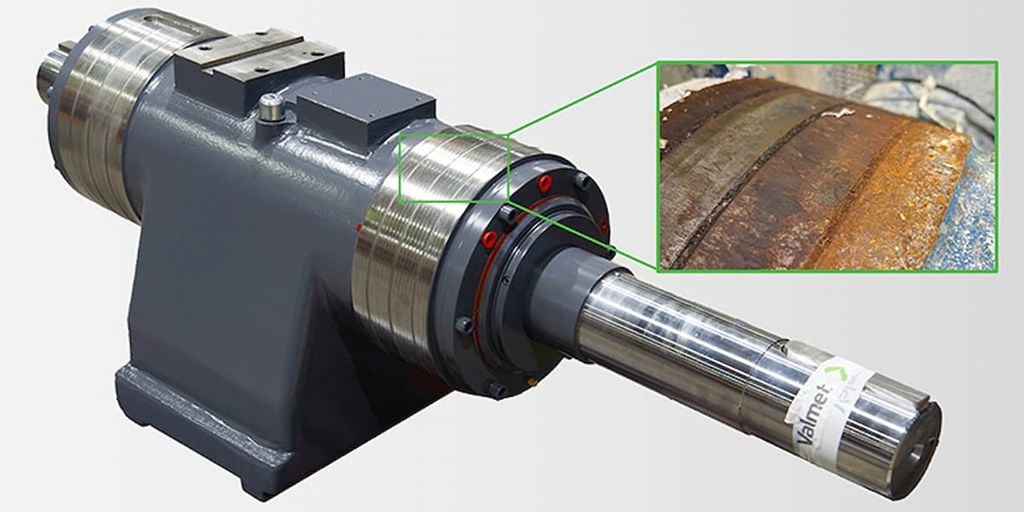

Case example: Poor condition of Conical refiner

A mill had a runnability issue with its low-consistency Valmet Conical RF-3 Refiner, mainly during refiner loading. Valmet carried out a mechanical audit, during which the refiner was opened, and its condition and damages were checked. It was discovered that the problems were mainly related to poor equipment maintenance. The damaged and rusty parts were replaced and reconditioned with special tools.

Thanks to the audit and the actions taken based on the findings, the refiner runnability is now back at a high and stable level. Additionally, the mill has minimized the risk of unplanned shutdowns.

A stock preparation audit is an excellent tool for supporting maintenance action planning to keep assets in the most productive condition

Optimal roll maintenance adds to the production performance

Numerous roll-related challenges can lead to serious issues throughout the tissue, board or paper making process. For example, rolls can cause long unplanned shutdowns and machine downtime when they need to be changed. Worn or outdated roll covers can also cause paper profile or runnability issues, as well as increasing energy usage through reduced dewatering.

A Valmet roll audit reveals issues like runnability problems and running time limitations related to rolls. Valmet’s experts will identify roll-related production bottlenecks, benchmark roll maintenance intervals, record current roll process values and evaluate roll covers. They will also check the mill’s spare roll situation and roll conditioning monitoring practices, evaluate roll grinding and storage facilities, and benchmark how your roll’s data is managed.

Valmet roll audits reveals possible underlying issues e.g. related to roll cover debonding or corrosion.

After the audit, Valmet will provide you with an audit report that includes tips for improving roll performance, reliability and maintenance costs. By knowing your roll condition, you will be able to reduce the risk of unplanned roll-related shutdowns or downtime thanks to optimized maintenance plans. You will also get an idea of the technology level of rolls and will be able to upgrade them and extend their run times based on the recommendations given.

Case example: Press suction roll cover damage in tissue machine

A tissue producer had press suction roll cover issues and turned to Valmet for help. A roll audit revealed cover damage and low groove volumes, as the groove design was suboptimal. The roll cover showed edge damage due to a high temperature and nip pressure.

The next time the rolls were ground, the groove design was changed according to an updated Valmet recommendation. Additionally, the end area dimensions were improved (chamfer design). Performance was improved, with no additional costs to the customer besides normal scheduled maintenance.

A roll audit provides a tool for planning roll maintenance systematically and spreading costs evenly over a longer period.

Text: Marjaana Lehtinen