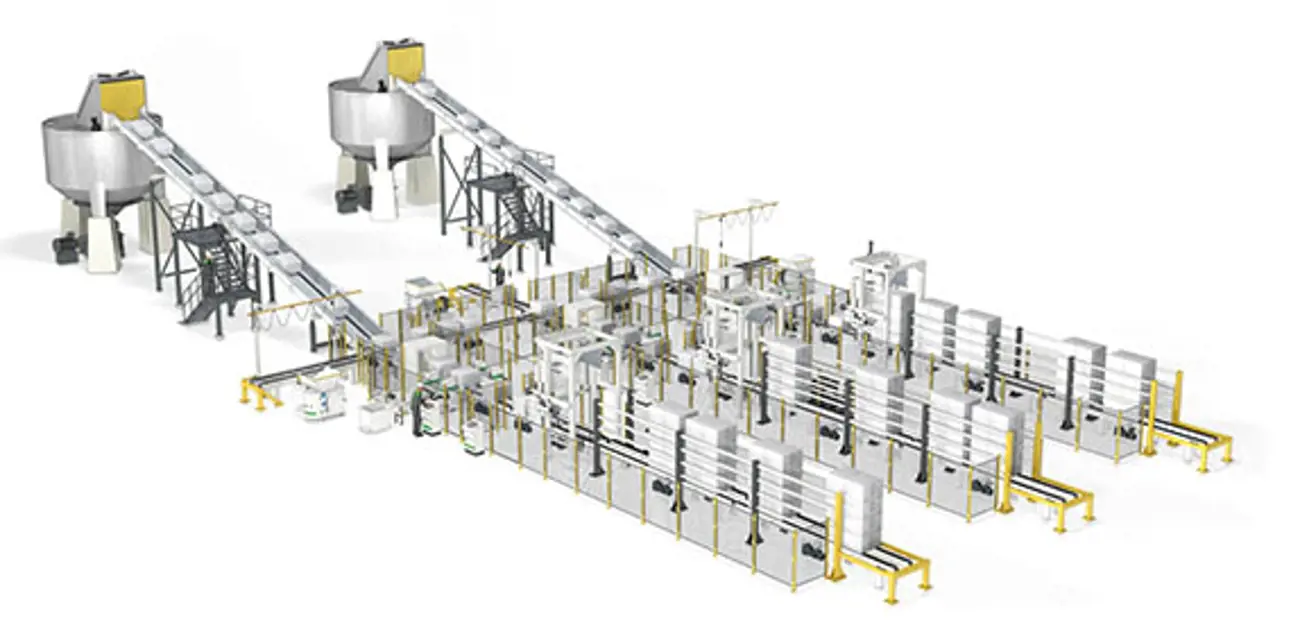

Valmet Pulper Feed System

Valmet’s modularized pulper feed system is flexible and offers a suitable solution for any paper, board or tissue mill. It increases safety, availability and productivity while reducing lifecycle costs.

Valmet’s dewiring solution for single bales can handle up to 140 bales per hour.

Valmet has applied its long experience to developing a best-in-class pulper feed system. With more than 50 systems sold, we can ensure smooth and disruption-free operation while employees are respected and protected. Intelligence is built into the system, and with real-time access to monitored data, it has never been easier to optimize operations.

Safety comes first

Valmet’s fully automatic pulper feed system offers higher productivity and efficiency, and improves staff safety by eliminating the risks associated with manual dewiring routines.

The main machines, used for dewiring and destacking, safely convert cut wire into compact recyclable coils. The installation is divided into safety zones. If anyone enters a safety zone, all power sources are interrupted, which ensures the highest possible safety for all employees. The safety system is always adapted to local safety laws and regulations before delivery.

“In designing pulper feed systems, we’re always thinking about how to prevent accidents and injuries. If the layout makes it difficult to operate the line, safety is sometimes neglected. It’s therefore important to resolve the safety issue, but still make the line accessible and easy to operate,” says Mats Backlund, Manager, Plant & Process Design at Valmet.

Smart system ensures quality

The intelligent system tracks each bale, bale set and bale unit throughout the line. Using absolute bale position tracking to ensure exceptionally reliable key data on production and quality, the system enhances efficiency, logistics and quality management.

Recipe handling is needed to ensure that the required pulp quality reaches the pulper. This can be a complex process for operators of manual recipe handling stations. Valmet’s advanced recipe handling software automatically tracks, sorts and collects bales. The software calculates the mix of bales needed to ensure the required quality and guides the movement of bales to keep the production flow constant.

Efficient wire removal

The machines in the pulper feed system are delivered as ready-to-use units designed for fast installation and start-up. Efficient daily operation is ensured by the superior control system, featuring PLC control equipment, which is operated and monitored via a touchscreen with an easy-to-use graphic interface. Wires are efficiently removed from bale stacks and single bales. Conveyor systems connect the machines for recipe handling, storage, transportation and manual dewiring. The system is autonomous, which means operators are free to perform other tasks. Operators can stop the system without generating cumulative defaults, which create extra work.

“We have the fastest dewiring solution available for single bales, with rates of up to 140 bales per hour when cutting the commonly used 2+2 wire configuration. Whether it’s automatic, semi-automatic or manual, our customers can always have a Valmet Pulper Feed System adapted to any special need and suitable tools to make operation as efficient as possible,” Per Jangdal, Sales Manager at Valmet concludes.

TEXT Kerstin Eriksson

Article published in Forward magazine 3/2019.