What makes single rolling design peristaltic pumps better than traditional shoe designed pumps?

Mar 10, 2022

The superintendent of the water treatment plant was examining shoe designed peristaltic pumps and single rolling design peristaltic pumps. The customer was convinced that Flowrox's peristaltic pump with only one compression per 360 degree revolution will lead to at least 3-5 times longer hose life time than conventional hose pumps. After installation, the first hoses in the Flowrox pumps lasted approximately for 9 months - a great result with 11 million revolutions while pumping abrasive lime.

Palm Bay (FL, USA) utilities department has three water treatment plants and one aquifer storage recovery well. The North Regional water treatment plant of Palm Bay, Florida uses both lime softening and reverse osmosis treatment processes. The product from each treatment process is blended in a clear well prior to distribution. The North Regional water treatment plant is also home to 100 million gallon aquifer storage recovery well, which can be utilized, if necessary, when demand is high or in times of drought.

The lime softening treatment plant can treat up to 10 million gallons per day and the reverse osmosis treatment plant can treat 1.5 million gallons per day. The North Regional water treatment plant evaluated possible pumps to deliver a 10% lime slurry at 25 psig and 20 gallons per minute. The superintendent of the facility was examining shoe designed peristaltic pumps and single rolling design peristaltic pumps.

Known Challenges with the Shoe Design Pumps:

It is a well known fact that the shoe design pumps compress their rubber hoses twice per every 360 revolution degree. The shoe design generates significant amounts of heat that reduces the hose life and therefore increases the operating costs (heat adds to further degradation of the rubber hoses). Running a 4” shoe design pump 24/7 at the maximum flow rate you will only be able to achieve about 200 gallons.

Based on these the superintendent realized the operating costs would be significantly higher for the shoe design peristaltic pumps.

Flowrox™ single roller design peristaltic pumps' hoses lasted approximately 9 months and survived in excess of 11 million revolutions while pumping abrasive lime slurry.

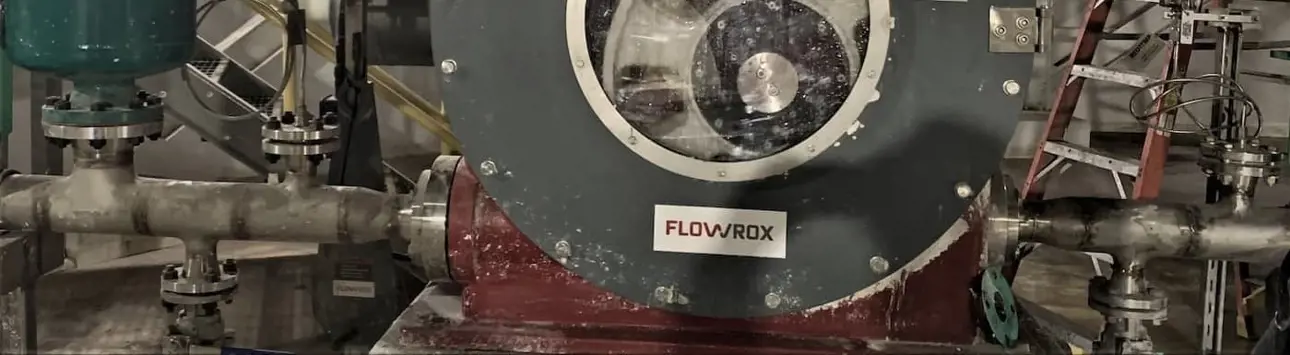

Flowrox 1.5” rolling design peristaltic pumps were chosen to minimize operating costs

The superintendent specified Flowrox LPP-T 1.5” hose pumps based on the technical merits and reduced operating costs of the single rolling design. The city of Palm Bay North Regional water treatment plant ordered three (3) Flowrox 1.5” rolling design peristaltic pumps to minimize operating costs for the city. The superintendent said, “These eccentric rolling design pumps are great, they just run and run and run”.

The first hoses in the Flowrox pumps lasted approximately for 9 months. The Flowrox hoses had 11 million revolutions while pumping abrasive lime.

Abrasive lime as a pumped medium

Lime is very aggressive and abrasive in pumps, valves and systems. The main reason is that lime does not dissolve in solution, rather it is a suspended solid. For this reason pockets, cavities or voids in pumps and valves will slowly be filled in with settling lime particles. These particles after settling will solidify or scale within the valve, pump, or piping. Many styles of pumps will fail extremely rapidly due to the abrasive nature of lime slurry and the scaling. The number or revolutions the Flowrox hoses were able to withstand over the 9-month time frame is truly astounding.

Lime has two attributes that make it very aggressive and abrasive in pumps, valves, and systems. First, lime does not dissolve in solution, rather it is a suspended solid. Then lime slurry also has a habit of scaling or forming into hard crusts around crevices or interior walls. Which leads to many styles of pumps will fail extremely rapidly due to the abrasive nature of lime slurry and the scaling. The number or revolutions the Flowrox hoses were able to withstand over the 9-month time frame is truly astounding

No overheating at high continuous flow rates

Because of the advanced rolling design, which eliminates friction, maximizes hose life and lowers energy consumption Flowrox pumps can produce more flow than shoe design peristaltic pumps. For instance, if you want to run a 4” shoe design pump 24/7 then the maximum flow rate you will be able to achieve is about 200 gallons per minute.

Energy efficiency, long hose life and low maintenance generates substantial savings during the life cycle of peristaltic pumps.

The reason for this limitation is that rubbing action of the shoes generate too much heat to be able to run the pumps at higher revolutions per minute. The LPPT4” is one of the world’s largest hose pumps that has a continuous 24/7 at 10 bar pressure with a flow rate of 440 gallons per minute. We can run 24/7 at these flow rates and not generate any significant heat and still provide hose life that is far superior to these other designs. In fact, in many cases we can supply a pump that is one or two sizes smaller to produce the same flow rate with much longer mean time between failure.

Text originally published in 2013, and slightly updated in April 2022, due to the company name change to Valmet. As of the 1st of April 2022, Flowrox brand belongs to Valmet.

Facts and benefits of Flowrox™ peristaltic pump' s single roller design:

Only one compression per 360 degree revolution: hose life in the single roller design will last at least 3-5 times longer than in a conventional hose pump.

A single roller design does not generate heat.

Requires only ~10% of the food grade glycerin compared to shoe design pumps.

Equipped with a patented hose flange and reliable in-line pipe connections, as well as a hose leak detection unit. Patented adjustment mechanism sense hose wear when compression is readjusted: helps to maximize hose lifetime and minimize the risk of over-compression.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeDiscover more about Flowrox pumps and read other customer stories