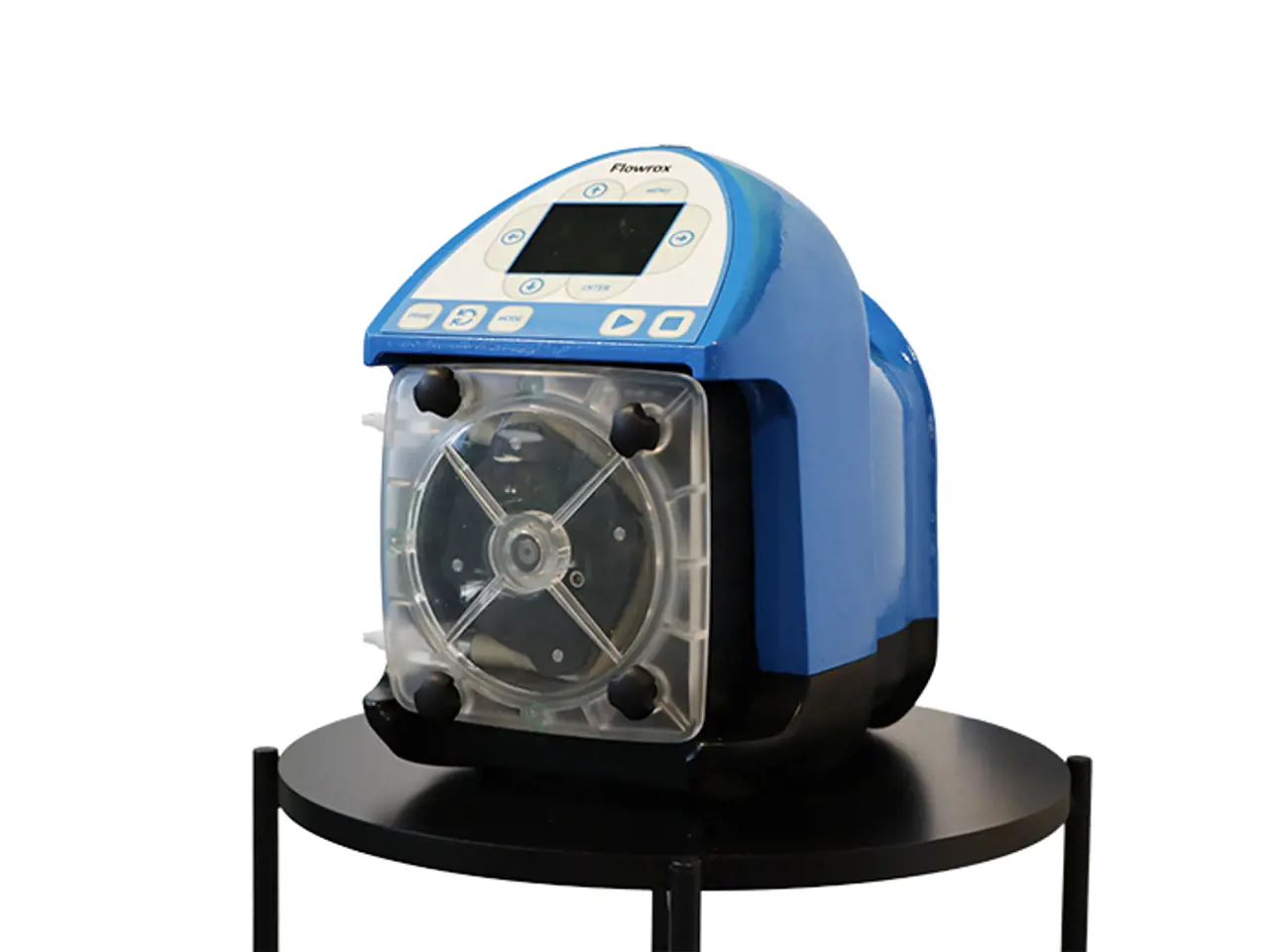

Upgrading wastewater treatment with Flowrox™ FXM metering pumps

Valmet’s Flowrox FXM metering pumps are at the forefront of precision chemical dosing in the wastewater industry. Their robust design and advanced features make them an essential component for any modern wastewater treatment facility.

The Flowrox FXM metering pumps stand out, with their advanced fieldbus connectivity capabilities supporting Ethernet/IP, Modbus, PROFINET, and PROFIBUS. Fieldbus technology is increasingly becoming the standard in industrial automation, offering a more efficient and integrated way of managing and controlling processes than traditional 4–20 mA analog signals. The pumps also offer other control options, including 4–20 mA, 0–10 VDC, pulse, and push button control, providing flexibility for integration into various systems.

Fieldbus systems provide a digital communication method that allows multiple devices to be connected on the same network, enabling real-time data exchange and more complex control algorithms. This contrasts with the 4–20 mA standard, which typically requires separate wiring for each device, leading to more complicated and costly installations.

The FXM metering pumps feature a built-in function logic for both input and output, enabling them to read inputs from pressure sensors, flow meters, or tank levels independently and adjust dosing accordingly. This enhances operational efficiency and adaptability. They also support dispensing and proportional dosing modes. In dispensing mode, the pump can be configured to dispense a specific volume of chemical on command, making it ideal for applications requiring precise batch dosing. In proportional dosing mode, the pump adjusts the chemical dosage based on the flowrate of the fluid being treated, which is particularly useful in applications where the flowrate varies.

They are designed with a 5,000:1 turndown ratio, allowing highly precise dosing across a wide range of flowrates. This is crucial for maintaining the accuracy and efficiency of wastewater treatment processes.

Safety is paramount in wastewater treatment, and the FXM pumps excel in this area with their capacitance-based non-contact tube leak detection. This advanced feature ensures that any leaks are detected and addressed promptly, stopping the pump and triggering an alarm for operators. This prevents potential hazards and maintains system integrity.

The multilingual digital touchpad available in five languages makes the FXM pumps user-friendly and accessible to operators worldwide. The pumps are also equipped with a power loss reboot functionality, which automatically resumes operation with the original parameters, minimizing downtime.

Security is another key advantage of them. Four-digit PIN protection prevents unauthorized access and tampering, ensuring that only authorized personnel can make adjustments.

A wide selection of tube materials is available, catering to different chemical compatibilities, ensuring that pumps can handle a variety of substances used in wastewater treatment. They are also designed with a dry run capability, allowing them to operate safely, even if the fluid supply is interrupted.

The NEMA 4X / IP66 enclosure ensures that pumps are protected from dust and water ingress, making them suitable for the harsh environmental conditions often found in wastewater treatment facilities.

In the wastewater industry, precise and reliable chemical dosing is critical. The FXM pumps have proven their worth in various applications, contributing to more efficient and effective wastewater treatment processes. For example, many wastewater treatment plants have successfully implemented FXM pumps, achieving significant improvements in their operations.

Simo Rounela

Automation Product Manager, Pumps

Certified Profinet Engineer

Valmet Flow Control P&S Flowrox Product Line

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe