The butterfly valve for any given situation

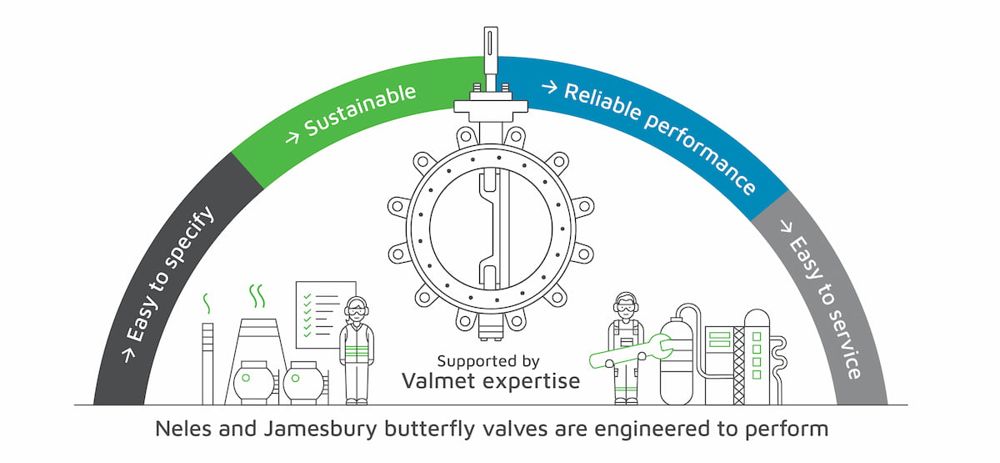

As the needs and requirements of modern process industries continue to change and become ever stricter, the role of safe and efficient valve solutions keep growing. The sustainable butterfly valve platform, which includes the metal-seated Neles Neldisc™ and soft-seated Jamesbury Wafer-Sphere™ valves, have been designed and developed over time to address today’s needs and challenges.

Proven performance with updated features

Neldisc™ and Wafer-Sphere™ have a long history and a proven track record in a wide range of industries and end use applications. The dedication to continuous development and new product upgrades and added features ensure that these valves are poised to exceed expectations in most industrial applications, regardless of end product, flow media, temperature or pressure. The comprehensive approach ensures a simple and easy selection and configuration process that enables efficient valve operations at a competitive lifecycle cost.

The comprehensive approach ensures a simple and easy selection and configuration process that enables efficient valve operations at a competitive lifecycle cost.

The design philosophy behind the newly upgraded Neldisc and Wafer-Sphere™ valves is based on taking the four most important industry trends into consideration – Safe and sustainable operations that adhere to today’s strict standards and regulations, extended process uptime based on long-lasting designs and easy serviceability, superior performance that maximizes process efficiency and yield and an inherent simplicity that makes these valves an attractive option for a wide range of applications.

Safety and sustainability in focus

Today’s global megatrends shine a spotlight on all things related to sustainability and safety. Increasingly tightening regulations related to fugitive emissions for example, have been a driving force behind the product development. Our field-proven designs have undergone upgrades to ensure compliance with all the latest severe standards.

By minimizing pressure losses and loss of valuable flow media through the valve construction, our butterfly valves help significantly reduce energy consumption related to pumping.

Reducing fugitive emissions not only improves on-site safety and eliminates harmful atmospheric pollution, but at the same time it plays an important role in improving energy efficiency. By minimizing pressure losses and loss of valuable flow media through the valve construction, our butterfly valves help significantly reduce energy consumption related to pumping. With energy being a significant cost for any industrial process, this is a factor that helps improve both the economical and environmental performance of your process.

Ensuring the health and safety of on-site personnel is also a key objective at all industrial production facilities. Driving down incident rates and minimizing risk of injury during daily operations and regular maintenance have been taken into careful consideration in the design of our butterfly valves. The reductions in component sizes and weight combined with designs for safe and ergonomic valve lifting improve the safety of service and maintenance personnel. At the same time our unique noise attenuation features improve the health and safety of the entire working environment.

Maximizing process uptime

There are two aspects minimizing expensive process downtime – ensuring the long-lasting high-quality performance of valves and optimizing the efficiency of planned service activities. Our Neldisc and Wafer-Sphere™ butterfly valves have been designed to address both aspects across each valve’s lifecycle.

For example, with the true metal to metal sealing design of the Neldisc, we can ensure the long-lasting tightness of the valve even when dealing with dirty flow media. The design also ensures high cycle service with fast operating times over the valve’s entire effective operating life. In comparison to many of the basic solutions on the market today, the reliability of Neldisc is clearly on superior level, as its construction does not contain any conventional features that often cause valve jamming, inconsistent torque or flaking of seating material. By extending the time between regular service shutdowns, we can help improve the profitability of your process and ensure the cost-efficiency of your valve solutions over time.

The smart modular design of these valves makes them both lightweight and compact in comparison to many of their competitors. The modular construction, small size and easy accessibility helps speed up safe and efficient service operations on site. It makes work faster while also helping reduce and simplify the required spare parts inventory. The modular platform also makes upgrades and modifications based on changing process requirements extremely easy. Overall, these valves help extend service life and shorten maintenance times, optimizing the uptime of your process.

Providing superior efficiency

Long-lasting tightness and optimized flow capacity are core components of efficient process performance. Our butterfly valves have been designed to provide you the highest Cv on the market, and thus, to help you reduce your energy consumption. In many cases our valves also allow you to achieve the required flow capacity even when sizing down. The low torque need of our smart valve construction gives the possibility to use smaller actuators and reduce the size and weight of your total package making piping supporting easier and reducing the vibrations occurring due to process variations. The long lasting tightness keeps your end-product quality on a high-level and improves the overall profitability of your process.

Stability is another key to an efficient process, high yield and superior end product quality. Our valve design allows for improved stability in the process by requiring less dynamic torque. The modular platform also provides you with plenty of additional high-performance options, severe noise and cavitation control, for example. For superior soft-seated butterfly valve performance and ultimate process stability our Wafer-Sphere valves offer our proprietary Xtreme sealing technology, not available from any other supplier on the valve market.

Making valve selection easy

The unique butterfly valve platform offers customers a truly one-for-all solution that they can be relied on. With several compatible valve bodies, shafts and sealing options available, the right valve configuration can be achieved for virtually any application, from soft-seated options for pure gasses to reliable metal-to-metal seated variations for pulp & paper applications. The cross-compatible components and standardized parts also make it simple and easy to upgrade valve performance without the need for replacing entire valves.

Neles butterfly valves offer superior performance under a wide range of process conditions.

Neles butterfly valves offer superior performance under a wide range of process conditions. Our true metal seated Neldisc for example can handle extreme temperature fluctuations ranging from -200°C cryogenic conditions all the way up to temperatures of +600°C. Regardless of flow media and the severity of the process conditions, we offer reliable performance with industry leading, long-lasting tightness and durability they have become known for over the past 45 years.

The text has been updated in April 2022, due to the company name change to Valmet.

For additional information, please contact sari.saxholm@valmet.com

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeLearn more about versatile butterfly valves