Reinventing reliability through Additive Manufacturing

Reinventing reliability is a critical mission that impacts technology and product development at Neles (now Valmet Flow Control business line). In this article, Jukka Borgman, Director of Technology Development, talks about Additive Manufacturing – more commonly known as 3D printing. He is very much involved to push technology development of AM within the company.

Complex internals

“Neles (now Valmet Flow Control) is one of the frontrunners in the valve business. In 2018, we shipped our first valves with 3D printed parts from our Helsinki plant. These 3D components allow the valves to perform in a particularly demanding application where they need to withstand numerous fast open-close cycles without maintenance.”

Borgman sees the main advantage of AM in the ability to design and manufacture complex internals that improve the functionality of the valve, also impacting its reliability, safety, and overall lifespan. “We see it as a robust and reliable production process that is ideal for small, complex shapes. Consider noise attenuation trims where 3D technology enables the design of parts that deliver more superior performance than conventionally-produced trims.”

Frontrunner in AM

Apart from 'design freedom', AM has additional benefits such as making tools, racks, or frames obsolete. It can also reduce production times, making it suitable for producing spare parts.

“For example, we AM-produced an attenuation ring in just 24 hours after which limited final machining was required, which added on just an extra day.”

We have been at the forefront of Additive Manufacturing in valve (part) production. We expect that it will become increasingly used in certain valve components; much of this will depend on the development of material standards.

Despite its advantages, Additive Manufacturing is not the magic potion for all manufacturing in the valve supply chain, Borgman says. “We have been at the forefront of AM in valve (part) production. We expect that it will become increasingly used in certain valve components; much of this will depend on the development of material standards. These are needed to assure end-users that the quality is guaranteed. However, there are efficient, cost-effective manufacturing methods for large volumes, such as casting, that are difficult to replace. There are also challenges to produce AM-parts for pressure-retaining vessels.”

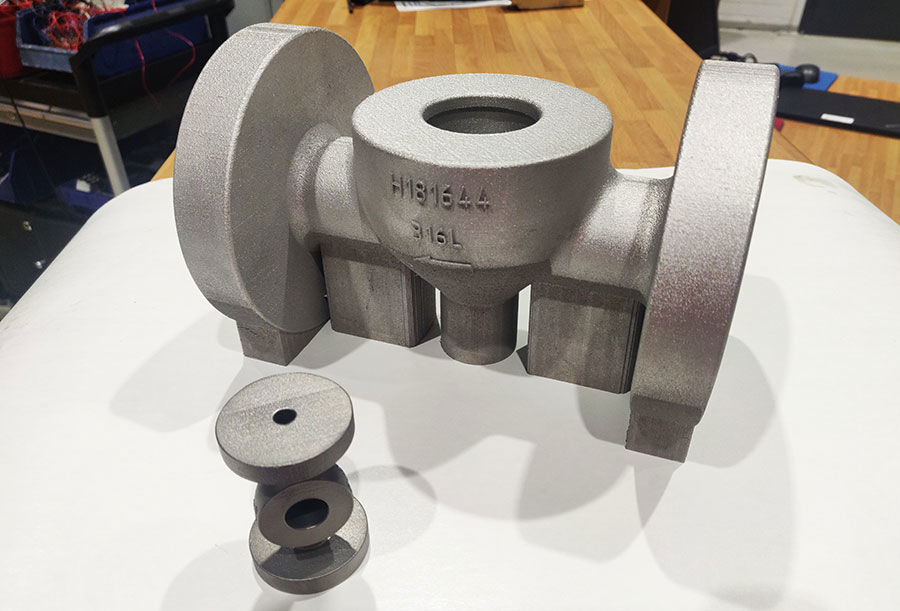

3D valve body

Having stated this, Neles manufactured an entire 3D printed valve body in Q4 of 2020. It was a standard ball valve (existing model, 1 inch, 63 bar) to be installed in a non-critical application at a power plant in northern Europe.

“The main goal with this project was to manufacture a safe valve that we will test extensively (tensile strength and impact resistance, etc.) before installation. We are very excited that this model will be tested in the field. It is also interesting that this particular end-user approached us to manufacture this valve. As for the reasons for the end-user to test this technology, I can’t disclose anything.”

Mr. Borgman states that the 3D printed material for the prototype of the valve has been already tested and that the results are better than expected. The valve could also take up less material than would be the case with casting. “However, for this particular valve, we will use a broader safety margin in terms of thickness. Again, safety is paramount. In later stages, we will optimize these parameters, of course.”

Opportunities of 3D printing – watch the video

On the video our experts Valtteri Koskinen, Senior Product Manager of Ball Valves and Tommi Bergström, Managet of Engineer Analysis discuss the opportunities of 3D printing in valve manufacturing and showcase some 3D printed parts.

Text by Lucien Joppen, Editor in chief Valve World. For additional information, please contact tommi.bergstrom@valmet.com

This article was originally published in Valve World magazine, February 2021 issue.

The original text has slightly been up-dated in March 2020, due to the time between the interview and the publishing date.

Text originally published in 2020, and slightly updated in April 2022, due to the company name change to Valmet. As of the 1st of April 2022, Neles is part of Valmet.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about R&D at Neles