New generation of modular butterfly valves on the market

“We want to offer our customers the broadest possible product selection. Our new series of modular butterfly valves brings together two valve platforms: Neldisc metal-seated triple eccentric butterfly valves and Wafer-Sphere soft-seated double eccentric butterfly valves. We were able to do this by standardizing the components in our butterfly valves so the top features of both valve types can be collected on the same platform. We’re talking about a brand-new generation of butterfly valve product families,” says Petri Ilonen, Product Manager for butterfly valves at Valmet.

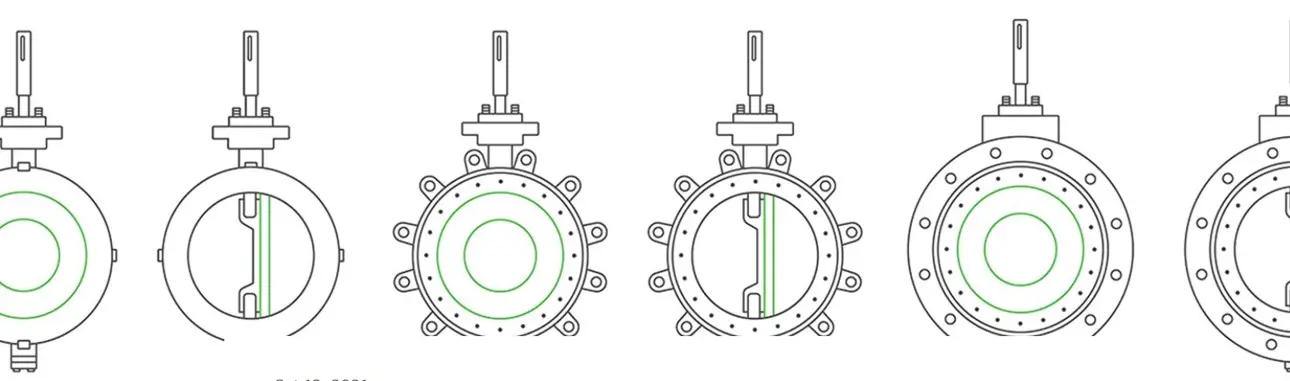

“The next-generation butterfly valves allow us to meet an even greater variety of needs with minor alterations. There are three different body types on offer, and the customer gets to choose their preferred shaft structure and either a metal-seated or soft-seated construction. These choices alone produce twelve different base configurations, and by switching parts, we can find solutions to satisfy even more challenging customer needs,” Petri Ilonen continues.

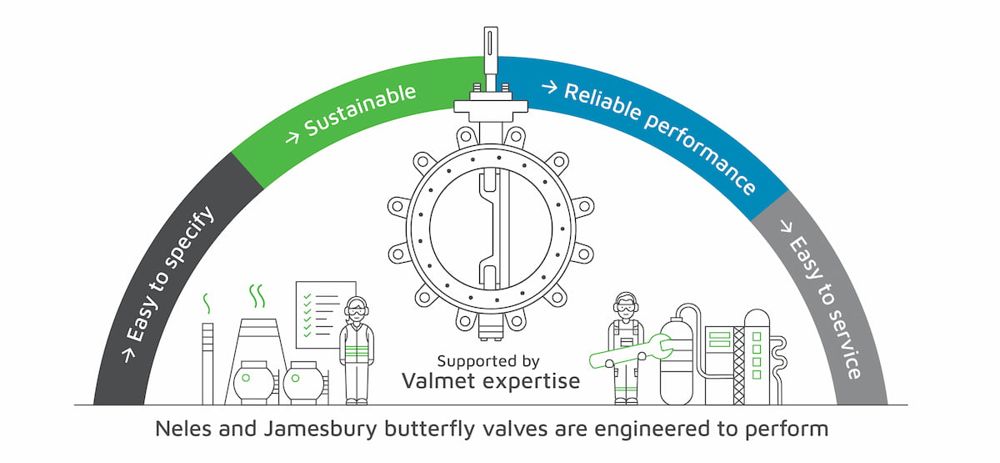

Valmet believes that standardizing butterfly valve components improves availability and shortens delivery times. It also enables late-configuration operating model. Parts can be exchanged if the process or customer requirements change for any reason. Upgrades for processes can also be done more easily. Reduced variation in valve components improves functionality and facilitates spare parts management.

You promise to make it easier to choose a butterfly valve. What is this based on?

“The big picture is that the situation within companies has changed. Almost every company used to have in-house experts with a very detailed understanding of the valve requirements for each process. Since then, these resources have been scaled down, so most companies no longer have specialist personnel with such narrow scopes of expertise. In our view, our new platform with a simplified offering and a clearer slate of choices also benefits our customers,” says Taija Hämäläinen, Vice President for the butterfly valves product line at Valmet.

What makes this technology the next generation?

“We’ve made some updates over the years, but this is definitely the biggest update made to both our butterfly valve categories over the existence of the different product families. What we’ve basically achieved here is picking the best technical properties of two proven products and fitting them into one platform. Also, with today’s developed simulation and manufacturing capabilities we have been able to improve existing constructions and features. So, the performance of the valve itself has also improved at the same time,” says Taija Hämäläinen.

According to Valmet, the metal-seated Neles butterfly valves were originally designed for paper industry applications, but they have also been adopted in other branches. The upgraded butterfly valve provides a more compact total package. It is both more efficient and easier to handle. The valve construction provides highest flow rates in the market, as verified by simulations and laboratory tests.

Valmet says environmental values have also always been key factors in research and development work. One of the goals was to reduce fugitive emissions. All new valves will be certified to the ISO 15848 standard by default. This has also been a requirement on the industry side.

“Low-emission solutions have been a standard requirement already for decades in the oil and gas industry. Recently, we’ve also noticed increased demand for certifications in the paper industry. Our new generation of butterfly valves was launched in June last year, so it is truly a cutting-edge product. Our approach using modular construction has been well received. The paper industry in particular has taken note of our environmental reasoning and the change in spare part logistics,” says Taija Hämäläinen.

Text: Leif Lindberg

For additional information, please contact sari.saxholm@valmet.com

Originally published in Paperi ja puu magazine, issue 3/2021.

The text has been updated in April 2022, due to the company name change to Valmet.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe