Innovation is embedded in our DNA

Innovation is embedded in our DNA

CHAPTER ONE Driver's seat

According to Kalle Suurpää, Vice President Valve Technology, developing innovative products and solutions is not a nice-to-have but definitely a need-to-have. “End users in several sectors are looking for more resilient, reliable and safe products. This is far from easy as process conditions have become more stringent. Due to process optimisations, valves should be able to withstand higher temperatures and pressures.

On top of these tighter requirements, valves also need to comply with stringent regulations in terms of fugitive emissions. Even in critical applications, cost is a determining factor. However there is a trend, Suurpää says, in which TCO has become more prevalent. “Plant owners strive to maximize the reliability of their assets and so tend to opt for more reliable and safer product solutions combined with well-planned maintenance strategies.”

Time-to-market is an issue that Neles has addressed within its technology development strategy. This accounts both for general product lines as customer-specific solutions.

“If we can provide better solutions faster, we are basically in the driver’s seat, Mr. Suurpää smiles. “The key words to realise the above objectives is to focus and to work smarter. Within Neles, we have adopted LEAN and Agile based methods to re-organise our technology and product development. What does this mean in real life? Well, it starts with input from our customers and the market in general that is generated by our sales and product management colleagues. This input is translated into product requirements after that our teams go to work. We tend to operate in fixed length, repeatable work cycles that allow us to review our incremental development results constantly to make sure that we answer the customer needs the best way. We remain flexible and agile, adapting our development to changing requirements or technical and economical challenges.

CHAPTER TWO Attitude change

Neles has already applied LEAN and Agile in the design process of its Neles NDX intelligent valve controller, shortening the projected time-to-market significantly. Kalle Suurpää: “Neles has gained extensive experience and knowledge on LEAN in production/manufacturing. The idea was to transfer this method to the way we develop technologies and related products. In general, we have been able to cut the time-to-market by a third or even a half. Our first case with the valve controller has been encouraging, to say the least. Especially in the early stages of product development, we were able to save valuable time. This had to do with focus, for example, by not overloading team members with parallel tasks, eliminating non-value add tasks and allocating sufficient man-hours.”

Apart from focus, Agile first and foremost requires a cultural and attitude change. “It is not about designing complete solution from the get-go but step-by-step exploring/working towards the complete, perfect end solution that is to the satisfaction of the end user.”

CHAPTER THREE Significant strides

Digitalisation, simulation testing and 3D-testing have become major facilitators in developing products in a faster, more efficient way, Kalle Suurpää states. “As mentioned, we have made significant strides, specially in the early stages of development. For all team members, both internal and external, it is imperative that progress is visible 24/7. Due to time and space constraints, we have developed a digital project environment. The advantage is remote accessibility and visibility. Even the physical whiteboards in our offices have been digitalised, allowing team members to click and drag tasks from ‘in progress’ to ‘completed’. So now team members can easily view the project in its entirety.” Automatic testing and simulation software also have contributed to significant time gains in early-stage development. “By implementing 3D-simulation software, we are able to run overnight parallel tests and simulations to assess what the implications are from - for example - design changes. By analysing these results in the morning, our team members are able to push through or return to the drawing board.” This allows fast verification of design alternatives but does not remove the rigorous testing of the selected final design.

Faster prototyping

In addition to digital solutions mentioned above, 3D-printing capabilities have contributed to faster and easier prototyping in later development stages. “Fast prototyping is essential in product development and generally requires lots of testing and iterations. This is where 3D printing comes in as a powerful, disruptive tool. We can quickly print prototypes, engage our rigorous testing programs and, together with our customer, find timely solutions that satisfy their needs. Having said this, we never compromise on quality and safety. Therefore, we still adhere to our strict testing programs in our factories and the field before we launch any new product to the market.”

Neles also has implemented 3D-technology in its manufacturing capabilities. In 2018, the company shipped the first batch of valves containing 3D-printed components. There are several advantages for end users, Kalle Suurpää says, such as shorter delivery times and enhanced functionalities. “Recently, we received an urgent call from a customer having issues with their existing valves. They needed an alternative valve with much quicker cycle speed and an exceptionally long service interval. By using 3D printing, we were able to develop and manufacture complex, cutting-edge components faster, with improved reliability, safety, and valve availability.”

24/7

progress visibility is imperative

CHAPTER FOUR Multimaterial solutions

As 3D-technology advances, Kalle Suurpää expects that Neles will increasingly make use of it, both in product development and manufacturing. “At the moment, we apply this technology exclusively for highlydemanding applications for which 3D-parts offer better performance. We don’t yet use 3D-technology for external parts as standards still have to be developed.” In the near future, he expects 3D-print multimaterial solutions will become a reality. “This is very interesting as we will able to develop and manufacture hybrid materials with increased functionalities and combining the advantages of different materials. At the moment, we use traditional production methods such as powder coating, isostatic pressing etc., but ultimately, we anticipate using 3D-technology to produce superior parts and products more efficiently.”

Huge impact

As Kalle Suurpää mentioned earlier, digitalisation will have a significant impact on the company’s technology development. “I wouldn’t prioritise this because other R&D domains, such as valve design and materials development, are equally important. However, the impact of digitalisation across the board on our company and supply chain will be huge.” Apart from the role in technology development - as has been discussed before - digitalisation is one of Neles’ key enablers to serve its customers better. This technology will facilitate more accurate and timely data storage and transfer about various domains, such as installed base, supply chain/logistics, asset monitoring and maintenance and so on.

A telling example is the company’s effort to streamline data transfer in project procurement and project execution. In this phase there are frequent exchanges of valve-related and engineering data going back and forth between EPC companies and suppliers. In the early procurement phase, EPCs require budgetary quotations from suppliers to estimate the project costs. As they move further in the procurement bids with end customers, EPCs require the suppliers to submit the final and firm quotations.

CHAPTER FIVE Focus on value-added activities

In the flow control sector, budget quotation and final quotation phases are relatively short. This leaves suppliers precious little time to produce high-quality proposals, especially if technical specifications are unexpectedly revised by clients at a later stage.

To address this issue, Neles has a project quotation team in place, staffed by experienced project quotation engineers. Adding to this strength the company has further improved response times by employing digital tools that facilitate two-way digital data exchange between the company and EPCs. In addition, Neles continues to enhance dimensional data that can be imported to customer’s own tools.

Kalle Suurpää: “we provide the best-in-industry distributor tools to support our partners. For example, they can independently create firm quotations for their clients, drastically reducing the response time to quotation inquiries to the final customers.” In addition, Neles boasts a range of service tools, such as installed base tools and performance tools, continues Suurpää: “we have embraced digitalization both to streamline project development but also as a tool in existing assets. Let’s take the installed base as an example. In many cases, these installed base lists are not up-to-date and incomplete. Over time, new items may have been added by hand, often using varying terminology. Valves may therefore be incorrectly listed as new items. This creates a top-heavy list, which is a real hindrance for effective asset management and maintenance. We have vast experience of this from the pulp and paper industry, where we have streamlined such lists from 5,000 items to just 550! Imagine the difference for the maintenance team – the installed base shrinking to little more than 10%. By harmonizing and streamlining these lists, significant savings in man hours and inventory costs can be achieved. It also paves the way for more advanced maintenance concepts, such as predictive maintenance.”

At Neles, digitalisation is therefore about making transactions between the company, its partners and final customers as easy as possible to improve efficiency. By using digital technology to automatize repetitive tasks, Neles’ people can be freed up to focus on activities that add value to the company and its customers.

Installed base items streamlined from 5,000 to

550

Kalle Suurpää

Meet Kalle Suurpää

Kalle Suurpää (Head of Valve Controls Business Line) has been working for the company since 2014. During his tenure, he has climbed the ranks to his current position in which he oversees technology development in valves and controllers.

“My background is technical/mechanical engineering. While at technical university, I visited Neles - earlier Metso - a couple of times. However, I started my career in mobile communication working at Nokia as a program manager where I managed cross-functional teams in developing products and related services. After 15 years with Nokia - and later Microsoft - I decided the time was ripe to change industry sectors. As Neles was already no stranger to me, I was eager to join this company, and I haven’t been disappointed. Neles has a strong drive to innovate and is characterised by a dynamic work environment. I am involved in many projects with highly trained and motivated colleagues. I wouldn’t wish for more.”

Neles' heritage

In 1973, Antti Nelimarkka, the creative engineer behind Neles range of valves, came up with an idea for a valve design that was quickly fine-tuned allowing production to commence in 1975. For the valves to be more reliable in demanding conditions and applications, Nelimarkka designed a metallic seat ring instead of a rubber one.

Neldisc was the first triple eccentric metal-seated butterfly valve in the world and was to become the norm in the industry. “Without a doubt, our valve product portfolio is built on remarkable innovations,” Kalle Suurpää states. “It is in our DNA to design and manufacture high-quality products that respond to customer demands and requirements/ standards. In the past decades, our company’s technology has evolved along with the trends that have shaped the manufacturing sector in general. Automation was high on the agenda in the 1990s, diagnostics and connectivity especially in the 2000s, and now we are reaching to industry 4.0 with the latest digital tools and technologies.”

Breakthrough

When asked about the most significant breakthrough innovations of recent years, Kalle Suurpää mentions the Neles NDX Valve Controller. “It is a product that has been designed based on exactly what our customers have asked for combined with over 50 years of in-house experience. We took the customer input and re-imagined the valve controller to make it safer and more reliable than ever before.”

One of the defining features is the interface which allows an easier and more comprehensive understanding of the internal workings of the valve. Suurpää: “we have improved the overall user experience with clear visual installation instructions to advanced functions that not only sound alarms but also suggest appropriate corrective actions. By doing so, the valve controller is easier to install with less room for human error and is also more cost-efficient in operation due to enhanced diagnostic capabilities.”

Why Neles develops wear protection materials

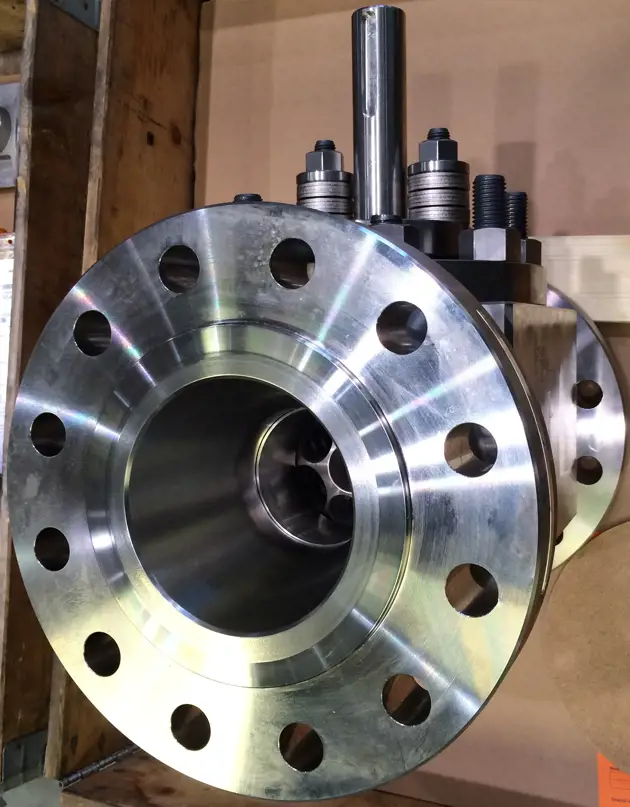

Material selection is highly relevant in severe service applications such as FCC slurry oil control, lime mud control, quench water control, acid leaching autoclaves and so on. For slurry media, Neles has developed innovations in wear-protection materials and functional coatings that have both contributed to supporting the use of metallic, metal-seated valves in severe control service.

“The use of wear-protection materials (branded as Neles Wear Block) in the construction of Neles ball valves has resulted in encouraging results in severe slurry control service, even with operating pressures up to 30 bar and temperatures of 200°C to 300°C,” says Kalle Suurpää. These materials include metal matrix composites, in which the erosion resistance approaches the performance of ceramic materials, while the mechanical and electrical characteristics are like metals. Depending on the process environment for each application, the final material selection is matched to specific requirements for corrosion, wear resistance and to the targeted maintenance schedule and overall lifetime.

Written by Lucien Joppen

Originally published as a Valve World cover story in June 2019.

The text has been up-dated in July 2020, due to company name change to Neles.

Kalle Suurpää

Vice President, Valve Controls

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe