Validated processes and competency enable long-term, safe operation of oxygen service valves

Validated processes and competency enable long-term, safe operation of oxygen service valves

CHAPTER ONE Cleaning, inspection, and testing procedures to meet industry standards and customer requirements

The inherent reactiveness of gases and liquids such as oxygen, ozone or chlorine mean they rank among the most hazardous applications for valves. Each stage of the lifecycle of these valves – design, material selection, manufacturing, cleaning, testing, packaging, handling, installation, operation, maintenance and modification – requires validated processes and competent personnel to enable long-term, safe operation at site.

Most of the existing literature on this topic calls attention to proper valve specification. On that account, this article will focus on considerations of cleanliness including keeping valves oil, grease and contamination-free at factory, at site and after maintenance. This article is not however intended as and shall not be understood as a Valmet oxygen cleaning instruction.

Valmet’s flow control business line follows strict cleaning, inspection and testing procedures to meet industry standards and customer requirements. Valve factories are evaluated and validated against these procedures at least once a year. Valmet also works closely with licensors, skid manufacturers and end users to promote good practices.

Oxygen fire hazards

Commercially produced oxygen can be separated by means of cryogenic distillation, vacuum swing adsorption, pressure swing adsorption (from air) or as a byproduct of water electrolysis. Industrial oxygen is then used for many purposes: in a basic oxygen furnace for making steel, in water pollution countermeasures, as a wood pulp bleaching chemical in the paper making process and in chemical processes such as the production of vinyl chloride, nitric acid, epoxyethane and hydrogen peroxide.

Oxygen is not flammable by itself but supports and accelerates combustion. Oxygen concentrations greater than 23.5% create a special fire hazard. There are three elements necessary for an oxygen valve fire to occur, and they are: oxidizer (oxygen), ignition source, and a flammable material (fuel).

In an oxygen-enriched environment (oxygen concentration in the range of 23.5-100%), the oxidizer is present all the time so is important to understand the potential ignition sources and mechanisms present in the valve. It is also important to know the limits for oxygen compatibility of the materials used for the valve components and lubricants because in the event of ignition, even the metal of the valve can become the fuel.

The following ignition mechanisms must be considered in a gaseous oxygen service when the contributing factors are present [1]:

- Particle impact

- Adiabatic compression heating

- Promoted ignition/kindling chain

- Mechanical friction

- Mechanical impact

- Thermal ignition

- Electrical arcing including static discharge

- Resonance

- Flow friction

Oxygen, heat, and fuel – the three components needed to ignite and sustain a fire – are frequently referred to as the "fire triangle".

CHAPTER TWO Cleaning methods

Importance of cleanliness

According to CGA G-4.1, valves used in oxygen systems (>23.5%) must be cleaned using a verified process and be shown to be free of contaminants. Maintaining the cleanliness of valves in contact with oxygen is essential to avoid ignition. The purpose is to eliminate unnecessary fuel in the valve since contaminants may be more easily ignited than the valve components or support ignition in other ways in the oxygen-enriched environment.

There are two types of contaminants, non-volatile residue (NVR) and particulate. If a valve for oxygen service is not cleaned to an appropriate level, there may be concerns of ignition of NVRs by adiabatic compression or other mechanisms and ignition of metallic particles by particle impact.

Hydrocarbon-based greases and oils, organic compounds, nitrates, phosphates, water-based detergents and cutting oils, some acids and solvents, metallic particles from rust or machining chips, lint, fibers, dust, weld slag, metal grindings and fillings are all common contaminants in piping systems.

ASTM G93, harmonized CGA G-4.1 and EIGA IGC Doc 33-18, and MSS-SP-138 provide excellent recommendations for cleaning processes, inspection methods, and various levels of cleanliness requirements. The following paragraphs include some common cleaning methods, inspection methods, and guidance on packaging, storage, installation, operation, and maintenance.

Mechanical cleaning

Mechanical cleaning is used to remove scale, coatings, paint, weld slag, loose material from the process and other solid contaminants and can include grit or ice blasting, wire brushing and grinding.

Aqueous cleaning can be done with hot water and steam cleaning, alkaline cleaning, acid cleaning, and detergent cleaning.

Hot water and steam cleaning is effective against oil, grease, dirt, and loose scale as well as welding and brazing residues and other contaminants. The addition of detergents can improve the performance of this cleaning method.

Alkaline cleaning uses caustic salt suspended in water to create a highly alkaline solution. It is effective against hydrocarbon oils, grease and waxes, and generally is enhanced by agitation and/or jet spraying. Typically, this is used for industrial parts washers. This process is greatly enhanced by ultrasonic agitation, but the solvent residue must be removed to prevent corrosion on some metallic materials.

Ultrasonic agitation.

Acid cleaning

Acid cleaning uses low pH solutions to remove oxides and other contaminants. Depending on the material to be cleaned, the following acids can be used:

- hydrochloric acid is used to remove scale, rust and oxides, and to strip platings (chrome, zinc, cadmium, etc.) and other coatings

- chromic and nitric acid are used for passivating, deoxidizing, brightening and removing alkaline residues in addition to cutting oils

- phosphoric acid removes oxides, light rust and fluxes.

- acids must be removed completely from the part prior to drying and, depending on the acid strength, may need a neutralizing process.

Detergent cleaning is performed using water solutions containing chemicals that have different functions. It is normally performed in an alkaline environment for better degreasing efficiency.

Semi-aqueous cleaning

Semi-aqueous cleaning uses a solvent-water emulsion, which is effective for removing heavy contaminants from parts like heavy grease wax or hard-to-remove soils. The emulsion may require agitation to maintain the mixture, and parts must be rinsed before the emulsion can dry. Otherwise, contaminants may re-deposit on the part that was cleaned.

Solvent cleaning removes organic contamination from the part surface. Solvents used for oxygen cleaning include acetone, isopropyl alcohol, etc.

Alcohol is a common solvent often used to revisit areas of concern identified by black (UV) light inspection. Solvents like alcohol evaporate completely, leaving no residue.

Vapor degreasing is a process in which a solvent is heated until it vaporizes, while the part is maintained at a lower temperature. The solvent then condenses and dissolves contaminants. The part must be oriented so that the condensed solvent can drain from the part by gravity. This method is very effective for inaccessible areas on parts but requires a contained environment for the part during the process.

CHAPTER THREE Inspection methods

Inspection can be done in two ways: qualitatively and quantitively. Qualitative methods are typically used for in-process part inspection, while quantitative methods are typically used to validate the cleaning process.

Qualitative methods include [2] a direct visual inspection with white light, This is the most common method to detect the presence of contamination such as oils, greases, preservatives, weld slag, chips, etc. This method can be used to detect particulate matter greater than 50 microns and moistures, oils, greases, in relatively large amount (for instance, >500mg/m2 of hydrocarbon on stainless steel surface).

Direct visual inspection is conducted with ultraviolet light. This method is only used after visual inspection with white light.

A wipe test is designed to identify contaminants in locations that have no direct line of sight. A clean, lint-free non-fluorescing cloth is used to lightly wipe the surface and then both white light and UV light are used to inspect the cloth.

A water break test is sensitive for detecting low contamination levels of oil and grease on the surface and the solvent extraction test is done by evaporating the solvent used for cleaning and obtaining the weight of the remaining effluent. Knowing the surface area of the part being cleaned allows one to derive the weight of residue per unit area which is the cleanliness level. Acceptable levels of residue vary according to user requirements.

UV light inspection for cleaned valve parts taking place in the clean room.

CHAPTER FOUR Particular attention to be given to storage, handling and installation at site

Specific instructions

Once a valve has been selected (oxygen-compatible material and the right shape), manufactured, cleaned and prepackaged, it is marked “cleaned for oxygen service” or “cleaned for special service” when intended for other reactive media. Specific instructions are given on how to package the product to preserve cleanliness during shipping and subsequent storage.

Packing and marking of oxygen valves.

Particular attention should be given to storage, handling and installation at site. Projects may face delays. Valve ownership may change hands. Contractors may involve sub-contractors who also need to be trained on oxygen risks and proper handling and installation practices.

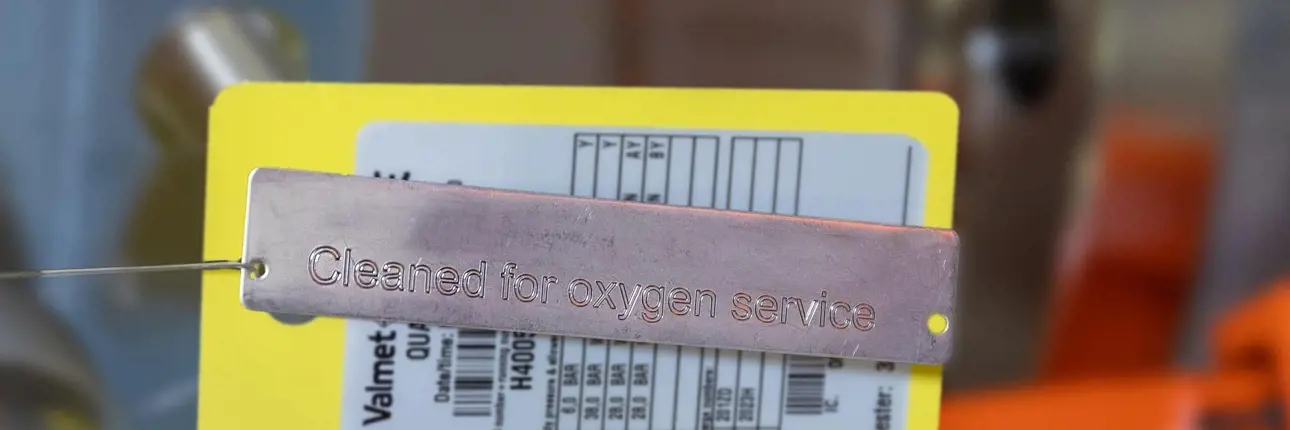

Recheck factory-attached tags to ensure that the valve is identified as having been processed for oxygen service and that the valve type and material conform to requirements of the service intended.

Factory-attached “cleaned for oxygen service” tag.

No compromises

Also ensure that valves are stored in their closed original transportation boxes with plastic covers intact up to the very last moments before installation. It’s essential that teams involved not compromise protection of the cleaned valve and that cleanliness be maintained throughout installation. Also, consider whether accessories can be added to the valve and set up without violating the protection. If the protection is compromised, are there procedural steps to identify and remediate any contamination? Are suitable facilities, tools and competent personnel available?

For these reasons, we recommend having our flow control commissioning or service specialist at site to help promote and monitor good practices. This will also help ensure any situation where protection is compromised is adequately and speedily addressed.

CHAPTER FIVE Oxygen-enriched environments present some risks and challenges in valves – how to avoid them?

Operation and maintenance

End users must keep cleanliness of oxygen service valves a priority throughout the operating lifetime of the valve. Operation of the valve must be limited to the original design purpose and follow instructions and warning in our Installation, Maintenance and Operation (IMO) manuals. Oxygen valves must also always be clearly identifiable by their tag, both at site and when removed from the pipeline.

Maintenance of oxygen service valves should only be performed by personnel trained in oxygen risks, and valves reassembled in a clean area using oxygen-compatible lubricants. For instance, a clean room provides a designated location where the environment limits dust airborne particles, where clean tools and clean assembly and test equipment can be stored. It can also provide controlled lighting for visual inspections. Every effort must be made to ensure that valves returned to oxygen service are dirt, oil and grease-free.

Valmet’s flow control service centers

Keep tabs on the quality and cleanliness of spare parts that come into contact with the medium, before they are inserted into the repaired valve. This is particularly important for soft goods (non-metallic parts such as o-rings, gaskets, etc.) which have lower auto-ignition temperatures. Neles and Jamesbury spare parts can be cleaned at the factory on request. However, further handling can contaminate these spare parts and it is the responsibility of company that services the valve to ensure the parts and the valve is properly cleaned and inspected before the valve is installed back in the pipeline.

For these reasons, Valmet recommends oxygen service valves to be sent to Valmet’s flow control service center or an authorized service partner. Several of Valmet’s flow control service centers are equipped with a dedicated controlled area and clean test equipment. Alternatively, the company has internal procedures in place which allow for oxygen cleaning in a temporary clean room, at a service center or at the site, for example during maintenance shutdowns. The company’s service specialists can also clean oxygen valves in the customer’s own clean room. Valmet’s flow control technicians are internally certified in oxygen valve cleaning, and competency is refreshed and validated every 2 years.

Risks and challenges

Oxygen-enriched environments present some risks and challenges in valves. Reducing these risks require special attention to valve material selection, valve design, manufacturing, operation and maintenance. There are critical steps in valve manufacturing and operation. These include but are not limited to: cleaning the valve components using validated cleaning and inspection methods, maintaining cleanliness during assembly, installation and storage, and working with personnel with validated competency in installing and maintaining oxygen valves. There are known best practices to follow at each process step for oxygen service. Valmet recommends end-users to work closely with the company to promote these good practices and to ensure long-term, safe operation of oxygen service valves.

Valmet’s Neles and Jamesbury valves are known for reliable performance in safety-critical environments such as oxygen-enriched mixtures and other reactive media. The company’s experience with these services was built with tens of thousands of valves “cleaned for oxygen service” and delivered globally over the past 60 years.

The merger of Valmet and Neles

Neles (formerly Metso Flow Control) merged with Valmet on April 1st of 2022 and became Valmet’s Flow Control Business Line. “This means that after the merger Valmet has become an even stronger, globally leading company with a unique and competitive offering to process industries”, Simo Sääskilahti says, President of the Flow Control Business Line. “Valmet develops and supplies a unique combination of competitive and reliable process technologies, services and automation solutions globally and now the offering is complemented with flow control solutions. The automation solutions cover distributed control systems, quality management systems, analyzers and measurements, related services and Industrial Internet solutions.” According to Mr Sääskilahti, the company can pride itself on over 65 years of experience in designing and manufacturing flow control solutions for various process sectors. “Building on this foundation of knowledge, expertise and insights, we are ready for the 21st century with exciting developments in renewable energies and more mature sectors such as oil and gas, pulp and paper or mining.”

REFERENCES:

1. Harmonized CGA G-4.4 and EIGA IGC Doc 13-12, “Oxygen Pipeline and Piping System”.

2. Harmonized CGA G-4.1 and EIGA IGC Doc 33-18, “Cleaning of Equipment for Oxygen

Service”.

This article has been originally published in Fugitive Emissions Journal, August 2022 issue as ’Cleaning: long-term. safe operation of oxygen service valves’. Link to the original article.

David Anderson

Director, Business service, FC MRO and Service Business Line, Valmet

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe