Innovative dry run solutions for progressive cavity pumps

Mar 24, 2025

Smarter pump protection: Multilayered dry run prevention for progressive cavity pumps

Progressive Cavity (PC) pumps are widely used in demanding applications, including pulp, paper and chemical industries and mining and minerals processing, where they handle thick pastes, shear-sensitive fluids, or abrasive slurries. However, one of the greatest risks to PC pumps is dry running – a condition where the pump operates without fluid, leading to excessive heat, stator damage, and costly downtime.

While traditional dry run protection relies solely on temperature monitoring, this method alone is not always enough. Some process media naturally lubricate the stator, delaying heat buildup and causing late detection. To address these challenges, Valmet's FlowroxTM PC pumps offer a multilayered approach, ensuring reliable protection in all operating conditions.

More than just temperature monitoring

Many PC pumps rely on basic temperature sensors embedded in the stator to detect dry running. While effective in many cases, it has limitations – especially in processes where the medium provides lubrication, delaying temperature spikes.

Valmet’s Flowrox PC pumps go beyond traditional protection with multiple advanced detection methods, ensuring the right protection for every application:

- Embedded Temperature Sensors – Still the industry standard and a proven method, ideal for applications where dry running causes immediate overheating

- VSD (Variable Speed Drive) Integration – Monitoring torque and power gives an early warning before temperature rises. While customer DCS and PLCs can analyze these parameters, most operators prefer ready-made solutions. Flowrox’s local smart analyzer processes this data automatically

- Vibration Monitoring – Useful in applications where dry running causes instability, helping detect anomalies before failure

- Capacitive Liquid Sensors – Provides early detection of liquid loss before damage occurs, though performance varies in sticky media applications

- Additional Process Sensors – Flow, pressure, and level sensors can be integrated to provide a custom protection package based on application needs.

Local smart unit – no complex programming required

Customers often don’t want to build custom analytics inside their DCS or PLC just to protect their pump. In Flowrox pumps, this is solved with a dedicated local smart analyzer that:

- Processes multiple sensor inputs (temperature, torque, vibration, etc.)

- Provides real-time dry run protection, stopping the pump before damage occurs

- Easily integrates into existing control systems, ensuring alarms are visible in plant operations without requiring complex programming

- IIoT-ready but fully operational in offline environments, catering to both digitally advanced and traditional facilities.

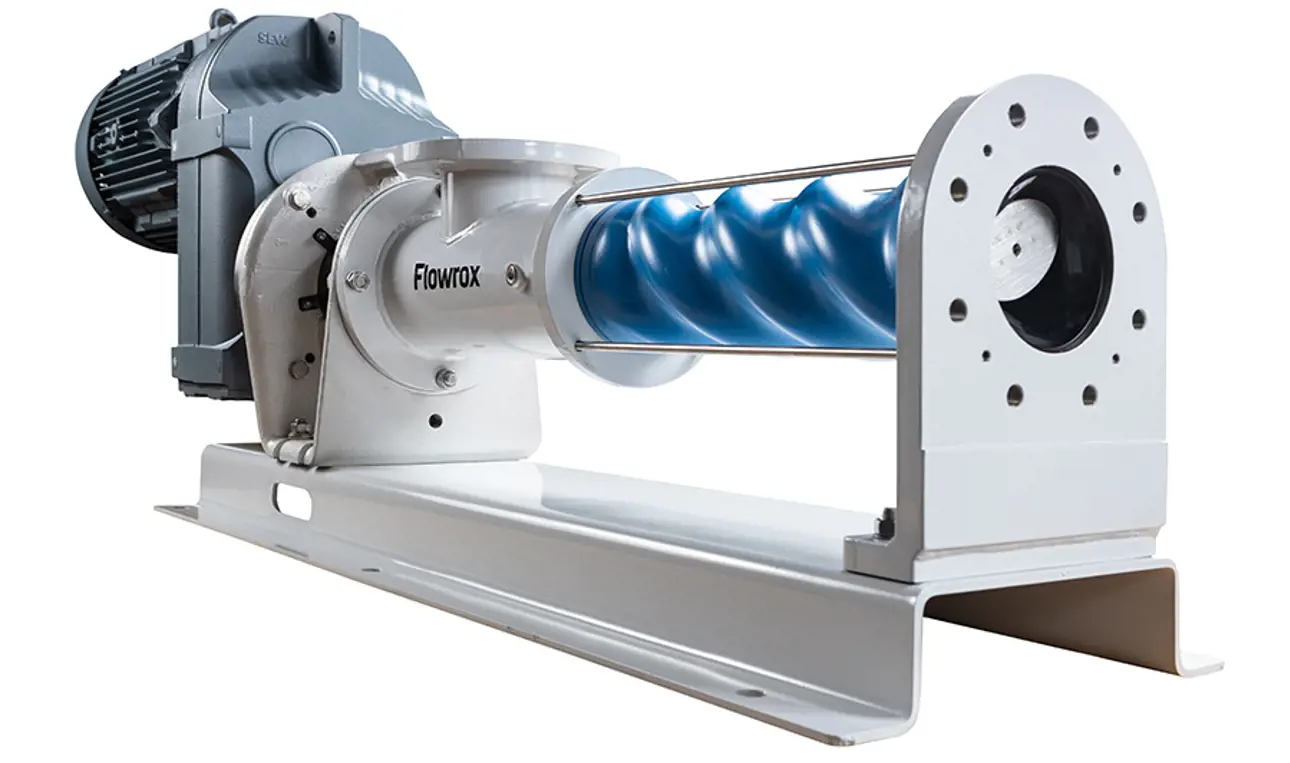

Flowrox PC pump incorporates precise 2/3-lobe elliptic rotor and spiral stator technology.

Built for demanding industries

Flowrox PC pumps are meticulously designed to deliver reliability even in the most challenging environments. They incorporate Evenwall® stator technology, which ensures uniform compression and significantly reduces wear, thereby enhancing durability. These pumps are constructed with heavy-duty materials, making them ideal for handling abrasive mining slurries, tailings, and demanding chemical processes. Additionally, they are engineered with linear flow characteristics, allowing consistent and efficient pumping performance, even when pressure conditions vary.

Easier selection – one system, many options

Choosing the right dry run protection should not be a complicated process. Flowrox PC pumps provide preconfigured options, enabling customers to select the most suitable solution without the need for an excessive engineering effort. The standard models are equipped with temperature-based protection, making them ideal for basic applications. For more advanced needs, configurations that integrate torque, vibration, or liquid sensing are available. Additionally, the smart monitoring unit streamlines the process by eliminating the necessity for complex DCS or PLC programming. Where remote diagnostics are required, IIoT features can also be included to enhance functionality.

Smarter protection, smoother operations

Dry running can severely damage pumps, resulting in unplanned downtime, high maintenance costs, and reduced productivity. Progressive cavity pumps equipped with flexible and reliable dry run protection ensure more efficient and smarter operations. These systems combine multiple detection methods that go beyond basic temperature monitoring, alongside a local smart analyzer that simplifies implementation. With integration-ready alarms for seamless plant operation and IIoT capabilities where necessary, these pumps are designed to protect equipment effectively while maintaining operational efficiency, even in challenging industrial environments.

Simo Rounela

Automation Product Manager, Pumps

Certified Profinet Engineer

Valmet Flow Control P&S Flowrox Product Line

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe