The best of both worlds - 45 years of butterfly valve expertise

Bringing together 45 years of butterfly valve expertise from two sides of the Atlantic Ocean: The path from a revolutionary idea to an industry-leading product family takes both time and dedication. The story of the versatile Neles™ butterfly valve platform spans back some 45 years and has its roots on two different continents. Today, the harmonized Neles™ Neldisc™ and Jamesbury™ Wafer-Sphere™ product family represents the best of both worlds.

The birth of Neldisc

The story of the Neldisc butterfly valve series began in Finland back in 1973 when the co-founder of Neles Oy, Antti Nelimarkka, asked his team to finalize a sketch he had drawn in his legendary notebook. Obsessed with the idea of achieving the ultimate sealing performance, the challenge was to develop a butterfly valve that could withstand temperatures up to 600°C (1100°F) and still maintain excellent tightness characteristics with long-lasting tightness and durability. As of April 2022. Neles is now Valmet Flow Control business line.

Nelimarkka had envisioned a metal seated valve working well in such conditions, but it was something that had never been done before. Some two years later the Neles R&D team came back to Nelimarkka with what is known as our unique triple offset valve design, an industry-first that is still in frequent use in butterfly valve products today. By the end of the development project IPR protection had been gained for the revolutionary elliptical disc design combined with the metallic seat ring in 13 different countries.

The modular, lightweight Neldisc product of today is the result of one man’s ambition paired with 45 years of continuous development. The spirit of Antti Nelimarkka can still be seen in the way we operate today.

The first deliveries were made in 1975, exceeding all expectations regarding tightness. Although the initial valve design has undergone many upgrades and updates over the years, the unique U-shaped metal seat of the Neldisc butterfly valve remains virtually unchanged, delivering reliable performance under today’s demanding industrial operating conditions. The modular, lightweight Neldisc product of today is the result of one man’s ambition paired with 45 years of continuous development. The spirit of Antti Nelimarkka can still be seen in the way we operate today.

Meanwhile across the Atlantic

In America a young inventor and entrepreneur, Howard G. Freeman had started his own experimental laboratory in the bedroom of his home on Jamesbury Drive in 1954. The work he carried out in that bedroom, and the company named after the street address would later become known as the origins of modern soft-seated valve technology. Technology that has served in the most critical operating environments, from submarines to space shuttles.

By the seventies, while Neles was busy perfecting the metal seated Neldisc butterfly valve design in Finland, across the Atlantic Ocean Freeman’s company, Jamesbury™ had moved on from the bedroom, and had already applied for their first patent for a bi-directional soft sealed valve. They were busy churning out large numbers of their flagship soft-seated butterfly valve, the Wafer-Sphere at their Worcester, Massachusetts plant.

A testament to Jamesbury’s leadership in soft-sealed technology is the number of high-profile patent infringement suits they have been forced to file over the years. The most notable of these is often referred to as the “Teflon Wars” in which Jamesbury™ took on the US Government and eventually won after a 17-year legal battle. Instead of Teflon, the flexible seal of today’s Wafer-Sphere butterfly valves is made of a unique seating material known as Xtreme™.

Better together

Little did anyone know at the time that these two products, the Neles™ Neldisc and Jamesbury™ Wafer-Sphere™ would meet down the line and form an unbeatable modular butterfly valve family that has the ability to meet all of today’s industrial butterfly valve needs with ease. Eventually in 1988 the companies would merge and bring together the by now well-established Neles™ metal seated valve portfolio and Jamesbury’s knowhow in soft-seated valves.

The two product families grew and developed independently of each other into flagship products in their respective metal-seated and soft-seated butterfly valve categories. Both products have seen numerous highlights over the years, from Jamesbury’s™ 48” butterfly valves used by NASA during space shuttle lift off to the 2004 delivery of the world’s largest metal seated Neldisc™ valve, which stands at 88” in size, to a gas application in China.

Today, under the Valmet, these two products have come together to form the modular butterfly valve platform. This fully harmonized valve platform has been created to help serve our customers’ ever-changing needs and requirements better than ever. We have taken more than 45 years of passionate product development on two different fronts to create a valve solution that delivers industry-leading tightness and process performance across a wide range of industries and applications.

Valves for today and tomorrow

Today our Neldisc™ and Wafer-Sphere™ butterfly valves can be found in reliable, long-lasting service around the world, improving the performance of industrial processes from the pulp and paper industry to demanding cryogenic gas processes. This comprehensive offering has the right valve for every flow media from chemicals and gasses to abrasive and dirty fluids. Our butterfly valve offering is the most comprehensive in the entire valve industry.

Today our Neldisc™ and Wafer-Sphere™ butterfly valves can be found in reliable, long-lasting service around the world, improving the performance of industrial processes from the pulp and paper industry to demanding cryogenic gas processes. Our butterfly valve offering is the most comprehensive in the entire valve industry.

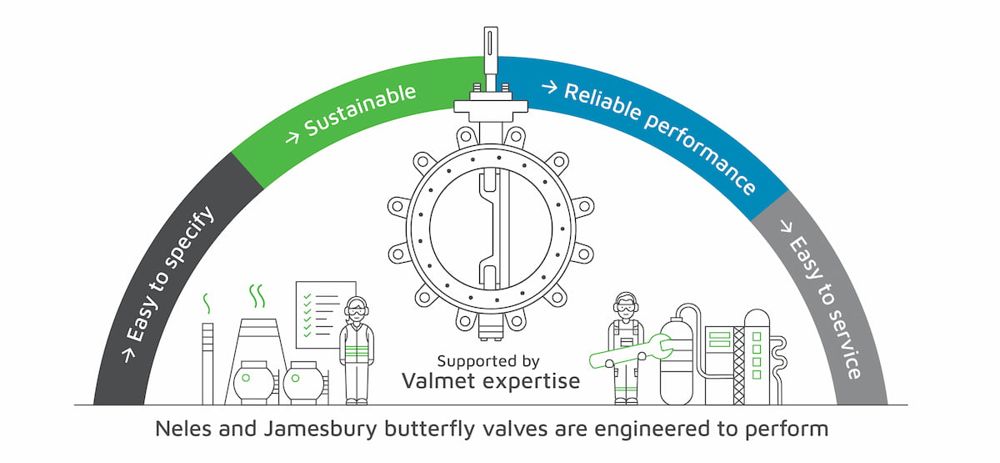

But the development of our butterfly valves is never over. More than four decades after a monumental industry-first, a new generation of Neldisc™ and Wafer-Sphere™ designs are again ready for long-lasting service. The latest updates make this modular valve family the benchmark for high-performance butterfly valves in terms of easy specification, reliable operations, sustainable performance and efficient serviceability. Stay tuned for more about recent developments to the next generation butterfly valve platform.

Text by Taija Hämäläinen. For additional information, please contact sari.saxholm@valmet.com

The text has been updated in April 2022, due to the company name change to Valmet.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about butterfly valves