Added value in the circular economy is not created out of thin air

The role of sustainable development as the guiding value in business and politics has significantly increased in the 2000s. The fight against climate change has raised the role of renewable natural resources to a new level. Overall, it is important to plan the use of all materials – both renewable and non-renewable – to be as efficient as possible. This thinking has given rise to the concept of the circular economy.

According to a study by Sitra, the circular economy offers Finland an opportunity worth EUR 1.5–2.5 billion in added value. However, it is apparently not quite clear at the moment where this amount comes from. It is clear that this added value does not appear automatically – it needs to be created on several fronts. Some of the measures needed are already in place, and it is only a question of utilizing them more widely. Some of them are still just ideas or are only becoming ideas, and utilizing them requires all the steps of innovation.

Financial and environmental benefits through resource efficiency

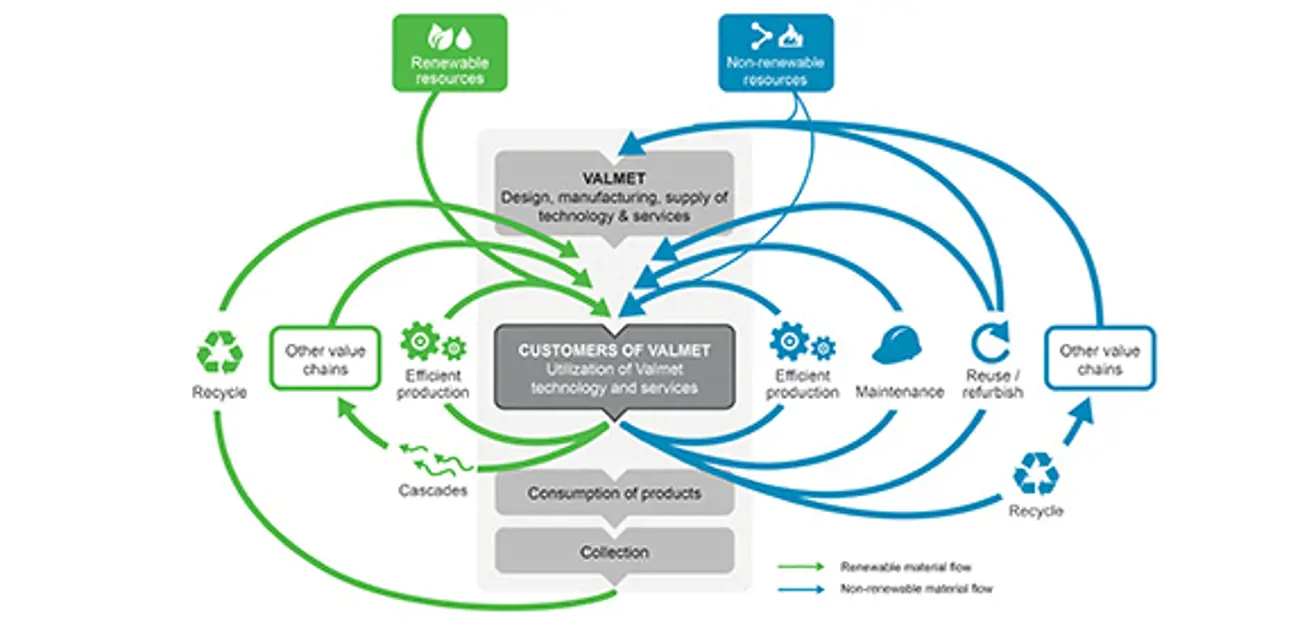

In Valmet's business, the circular economy is an everyday matter. We believe that the efficient use of resources is smart for both the environment and business. Both in our own production and in the technologies we offer to the pulp, paper and energy industries, it is clear that no raw materials should be used more than is necessary. In the production process, any extra material used involves costs, both when purchased and in secondary flows, such as waste disposal.

In practice, water and energy efficiency has been directing product development e.g. in the paper industry in the past years. Valmet's OptiConceptM paper and board machine, launched in 2011, uses about 15–30% less water and energy compared to a machine of the previous generation. Another similar example is Valmet's energy efficient Advantage NTT tissue machine, which consumes 10–20% less fiber raw material than a tissue machine of an earlier generation.

Maintenance and upgrades extend operating times

Our starting point is that machines and equipment are engineered so that consumables can be replaced and the technical useful life of equipment can be extended through regular service and maintenance. In fact, nearly half of Valmet's net sales comes from service business. Maximizing the useful life of equipment is probably not such a self-evident matter in, for instance, consumer electronics. Some mobile phone manufacturers design their phones so that the battery cannot be replaced or the amount of memory increased. These companies could learn some lessons from the forest or energy industry, where equipment is serviced and upgraded so that it operates for decades.

The changing market situation and regulatory requirements must be taken into account when the same equipment is used for several decades. Thanks to fine engineering and product development, we can transform a printing paper machine that has commercially reached the end of its road into a board machine, or change a coal-fired boiler to run on biofuel through reasonably small investments.

New bio-based products

The utilization of new renewable products in other value chains is also at the core of the circular economy. An excellent example of this is lignin. Lignin is a binding agent in wood. Until now, it has been incinerated to produce energy in pulp manufacturing as part of chemicals recycling. In 2011, Valmet introduced LignoBoost technology to the market, which permits the recovery of lignin and its utilization in e.g. the production of biochemicals or biomaterials.

Innovations

In order to better reach all the potential for added value offered by the circular economy, different parties must be involved in the development. The success of a development project is facilitated by the involvement of different parties in the value chain, such as end users of the product, technology developers, subcontractors, experts on the raw material chain, applied research, investors, and perhaps startup companies as well. When working together, the roles and responsibilities of the different parties must be taken into account, and risk management has to be agreed upon.

In our own business, we have already identified areas where we can create new business and apply the circular economy more efficiently. New opportunities can also be found in the interfaces between different fields of industry. The implementation requires systematic effort and courage.

I challenge all my colleagues in companies, research institutes and administration to join the work of building innovations that take the added value of the circular economy from idea into practice.

Ari Saario

Director, Research and Development, Valmet

Ari Saario is the Head of Valmet's R&D operations. He has versatile experience of more than 10 years in research and technology development, R&D team leadership, innovation networks and R&D funding.