Questions and answers about replacing gas with electricity in coating drying

Many paper makers are considering replacing gas with electricity in coating drying. To make you feel more secure with the change, we have answered frequently asked questions about replacing gas with electricity and infra-red dryers with air dryers.

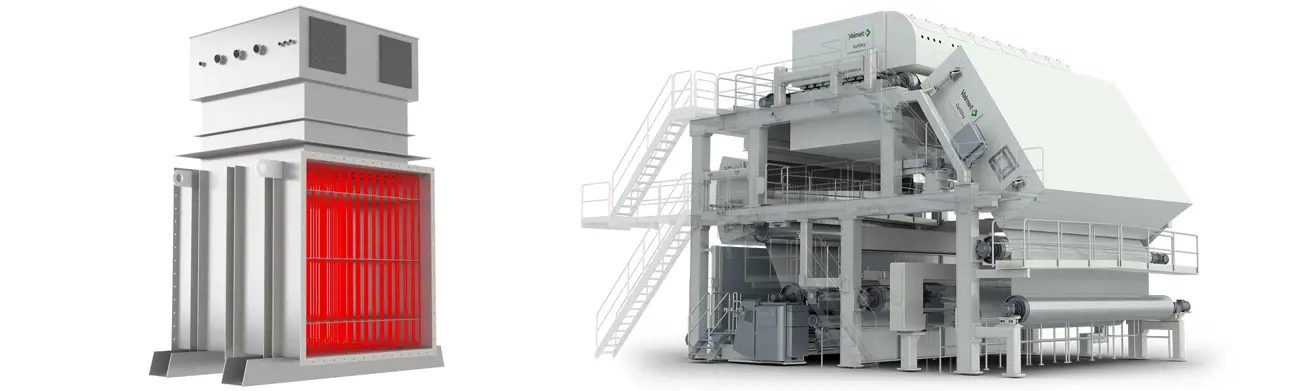

1. Does the modification from a gas burner to an electric heater have any impact on the required space or layout? What about the modification from an infra-red dryer to an air dryer?

The modifications may have a different space requirement than the existing solution. However, Valmet’s experts can find a layout which works for your requirements.

2. Do OptiDry coating air dryers have any impact on the quality of the paper?

Compared to an infra-red dryer, you will get less mottling, improved gloss, and better smoothness with OptiDry coating air dryers. With air drying, evaporation starts instantly, and free water evaporation keeps the coat temperature low. A lower temperature also means lower partial steam pressure inside the coating, decreasing the flow into the paper and thus helping to keep the color on the surface.

3. What is the estimated cost of the modification? How long is the payback time?

Replacing an infra dryer with an air dryer saves 50 percent of the energy costs and at least 90 percent of the maintenance costs. Depending on the energy price etc., the payback time is typically around two years.

The modification of an existing air dryer from gas to electricity is often done as part of an emission reduce program. In addition, you can get energy savings of around 10 percent. Subsidies are often available for these investments from the local authorities.

4. How do OptiDry coating air dryers compare to infra-red dryers in energy efficiency?

An air dryer’s energy efficiency is approximately 70–80 percent, thanks to high drying rates and effective nozzle technology. An infra-red dyer energy efficiency is only 25–35 percent. The energy savings are 50 percent compared to infra-red drying.

5. What is the lifetime of heating elements in electric heating?

The lifetime of an electric heater is related to the process temperature and the heating element design. A minimum lifetime in high temperature solutions can easily be more than 10 years.

6. What is the response time with electric heating compared to gas burners?

The response time of an electric heater is longer than that of a gas heater. With appropriate technical solutions and correct procedures like the preheating of the system, the effect on production is negligible in practice.

7. How long is the shutdown time for a coating dryer rebuild when replacing a gas burner with an electric heater?

The shutdown time depends on the number of dryers to be modified. OptiDry Coat is a cost-effective rebuild solution with a short shutdown time – typically three to four days, but no more than one week.

8. How long is the shutdown time for a coating dryer rebuild when replacing an infra-red dryer with an air dryer?

The shutdown time depends on the number of dryers to be modified. OptiDry Coat is a cost-effective rebuild solution with a short shutdown time – typically one week.

9. How can the change from an infra-red dryer to an air dryer contribute to a safer working environment?

With OptiDry coating air dryers, working conditions improve due to significantly lower temperatures around the dryer. The fire hazard is also reduced due to considerably lower surface temperatures: on an IR emitter surface, more than 1,200 °C, vs. less than 450 °C on an OptiDry nozzle surface.

10. How do OptiDry coating air dryers affect maintenance costs when replacing an infra-red dryer?

The maintenance cost is reduced because costly wearing parts like emitter lamps are not required, and less service time is needed for the equipment than with infra-red dryers. The annual maintenance cost is reduced by at least 90 percent.

11. Are OptiDry coating air dryers only suitable for specific grades or a specific machine type?

Valmet uses OptiDry air drying in all coating drying deliveries regardless of web widths, grades or whether it is a one-sided or two-sided application. The coating air dryers are suitable for both new machines and rebuilds. They also have several heating possibilities: electricity, steam and gas.

Want to talk to our coating drying experts?

If you wish to get further information, fill in the contact form and our experts will contact you shortly.

Contact our expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsWant to talk to our coating drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts