A new start with an OCC grade conversion at Burgo Verzuolo PM 9

In 2020, Burgo Group’s Verzuolo Mill converted their existing paper machine into a board machine, a decision made to meet the market’s growing demand for packaging material. Converting to OCC grades allowed the mill to transition to producing high-quality container board grades while using minimal virgin fiber and with low operating costs. Although the rebuild project was extensive, everyone involved was very pleased with the results once the machine was brought online.

With an ever-growing need for packaging and container board grades, Burgo Verzuolo’s PM9 saw an opportunity. Their existing product portfolio didn’t meet the market demand, as the machine was originally built for paper grades by Valmet 20 years ago. Burgo Verzuolo decided that it was time for a renovation. With a long history of successful collaboration, it made sense for Valmet and Burgo Verzuolo to partner once again for this grade conversion rebuild project. The scope included modifications to the paper machine and a new OCC line that was purpose-built to enhance the board machine’s operations in the Verzuolo Mill.

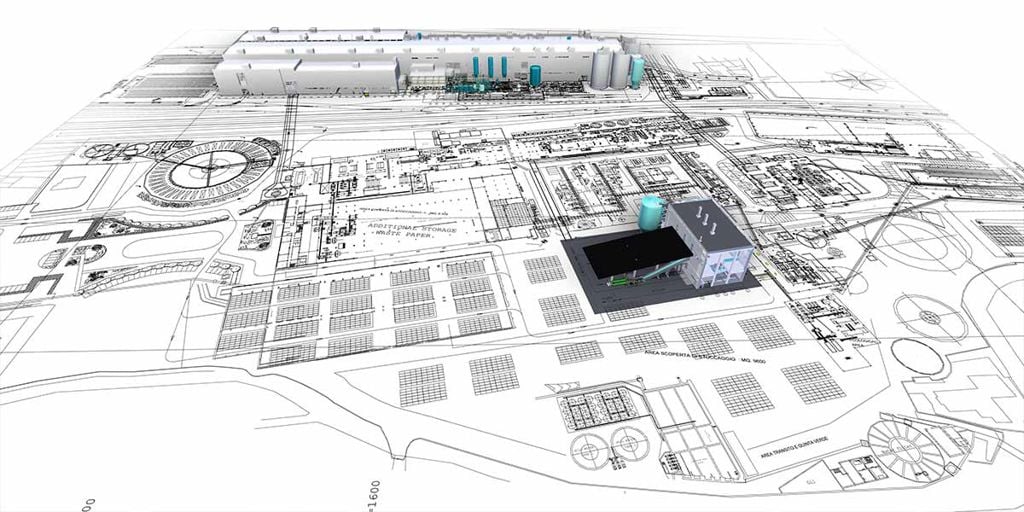

Layout from Burgo Verzuolo site: Paper machine building at the back, OCC line in the front

High-quality boards on the “big, beautiful machine”

Since the production process of containerboard grades is significantly different from paper production, the renovated board machine looks quite different from it used to. The starting point was a good one: according to Jani Hakola, Project Manager at Burgo, PM 9 was a big and beautiful machine. The wet-end went through big changes: The forming section had to be rebuilt to increase drainage capacity and press section was modified to double-felted design. There were also some modifications made in the dry-end when the machine had to be lengthened to fit in new post-drying section and film coater was converted to size application.

Screen capture from Burgo's timelapse video of PM9's wet-end installation

“Having completed this extensive project finally on January 5, 2020, we got the paper on reel and everybody was really happy. Actually, we were really lucky to start-up the machine on time without suffering too much from the coronavirus. Soon after the startup, the travelling was heavily restricted, so this was one of the luckiest start-ups that I remember”, says Jani Hakola.

Now the newly renovated board machine is running smoothly and Burgo and its customers have been very pleased with the quality of the board. “The quality of the board is great: it is cleaner compared to the average quality in Italy. All the strength properties have been consistently reached, and there is really no trouble on maintaining this quality level”, says Hakola. The board machine has also reached the capacity goals set to it. ”Our board machine never really had any issues with runnability and today it is still running really nicely”, he adds.

OCC technology: Taking the most out of every fiber, again and again

The new OCC line was built for the production of high-quality board with optimized final pulp quality, yield, and operating costs. The line concept included two vertical pulping lines with bale handling, HC cleaning, fractionation, lightweight and heavy-weight cleaning and fine screening of long fiber, and disc filter thickening. Impurities removed in the process are directed to the reject handling line, also part of Valmet’s delivery. The new OCC line is running smoothly, and it has reached all the goals set to it. “Our new stock preparation line is very efficient and operating well. We have never had to stop the paper machine due to a lack of stock”, says Hakola.

Raw material at Burgo Verzuolo

Improving the performance together

After the start-up, Valmet and Burgo Verzuolo mill have continued their partnership to improve the runnability of the new board machine and OCC line. “We continue working with Valmet in a co-operation to improve production line’s operations. One of our goals is to improve our cost management by optimizing the raw material usage” says Hakola.

Even though the start-up might have been the luckiest one, the project teams of Burgo and Valmet were facing a completely new situation during the ramp-up phase. Due to the pandemic, the traditional way of working side by side at the machine was no longer possible. The teams had to find new ways of collaborating. The answer was remote connections and remote machine diagnostics and analyses, which were made possible due to full scope control and quality systems automation that PM9 has been equipped with.

As is the case with any major projects, unforeseen issues may occur. In Burgo Verzuolo, the new OCC line fine screening experienced some challenges, which initially surfaced with high power consumption. As international travel was restricted, expert data analysis was done by Valmet remotely. Together with the local Valmeteers’ and mill team’s support, the root cause was quickly traced to bearing design. “The solution was found fast, and at the end everyone was happy. We were happy to see that the response time from Valmet was short and newly designed bearings were delivered to the site fast. The shutdown for changing the defective parts was planned well without causing any disturbance to our production process”, says Hakola.

Equipment for cleaning and fine screening at Burgo Verzuolo

Exceeding expectations

Ultimately, the renovated board machine has operated as planned, and in some cases even better. “The board machine has been working well and productivity is growing steadily. In some ways, the machine productivity has even exceeded our expectations. The dry-solids content at the press section has been on a good level, which is one reason why the machine productivity has been so good”, says Hakola. The new OCC line has been working as expected, too: “The OCC line’s material efficiency is at a good level and the line has been working very reliably”, adds Hakola.

Soon there will be some changes taking place at the Verzuolo Mill, but its future seems bright. Smurfit Kappa recently acquired the mill and the production is continuing with its new owner. According to Hakola: “Smurfit Kappa* acquired themselves an excellent production facility.”

Text: Veera Silakoski

Images: Jani Hakola, Hanna Jokinen

*) Smurfit Kappa completed acquisition of Verzuolo mill in October, 2021

Related articles