Valmet Wet End Analyzer takes advantage of new technology and continued development

After more than 10 years the Valmet Wet End Analyzer, Valmet WEM, is still the only available online measurement system to provide tissue, board and papermakers with all the relevant wet end variables for effective wet end management. In keeping with Valmet’s continuous technical improvement policy, Valmet WEM has now been updated with new state of art technology based on extensive field experience and user feedback.

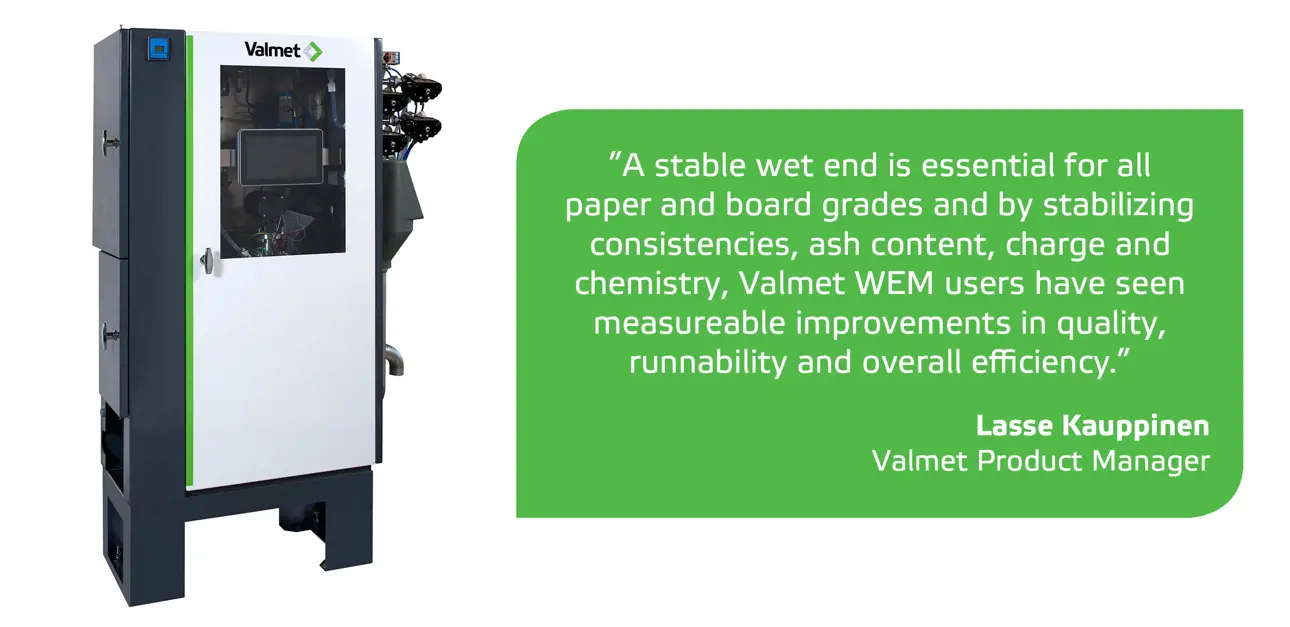

Development of the analyzer has resulted in advanced measurement capabilities for superior chemical dosage control, easier implementation to provide immediate process benefits, and enhanced reliability with remote diagnostics capability. The new analyzer can handle up to six sample points with a combination of up to four optional modules measuring charge, chemistry (pH, temperature, conductivity and redox), total/ash consistency, and turbidity. According to Lasse Kauppinen, Valmet Product Manager, “A stable wet end is essential for all paper and board grades and by stabilizing consistencies, ash content, charge and chemistry, Valmet WEM users have seen measureable improvements in quality, runnability and overall efficiency.”

Navigating the complex wet end world

As the number, complexity and interactions of chemicals used in the wet end increases, this modular, multiline analyzer is perfect for profound process monitoring as well as providing the opportunity for both enhanced manual and even automatic dosage control of retention aids, biocides, and fixatives among others. Applicable to all grades of paper, board and tissue, each analyzer is equipped with the measurement modules needed in a particular customer process. With four measurement modules (consistency, charge, chemistry and turbidity) in one cabinet, installation is simplified, safety improved and overall cost of ownership reduced. Remote diagnostics, part of the Valmet Industrial Internet solution, through the Secomea secure remote connection ensures that the extensive expertise of Valmet is never far away.

Upgrades available

Valmet takes care of users. As a part of lifecycle management, partial upgrade packages, including for example the redesigned charge module with enhanced materials, dimensions and cleaning systems, are also available for existing users.

Complete solutions

Valmet WEM is part of the comprehensive paper quality program from Valmet covering all paper machine measurement and control needs from consistency in stock preparation right up to the reel with complete Valmet IQ quality control systems.