The future energy system calls for flexibility

Valmet’s automation, control and process solutions help respond to the requirements of the future energy system

By increasing the flexibility of traditional production plants, Valmet’s automation, control and process solutions help respond to the requirements of the future energy system. There’s a huge potential for flexibility, especially at combined heat and power plants (CHP) as they act as links between electricity and district heating networks. When needed, it is possible to utilize district heating networks and their heat storages to optimize electricity production. Even at traditional combustion plants, the readiness for rapid load changes and ultra-low minimum loads can be improved by means of equipment, process and control technology.

These issues were studied in the recently completed FLEXe research program (Flexible Energy Systems) by Valmet’s experts, Tampere University of Technology and VTT Technical Research Centre of Finland, among others. Valmet contributed its automation, control, process and fuel know-how to the program.

“The program highlighted cooperation between the participants as well as promoted an understanding of the whole energy chain and the changes taking place in it. Valmet’s strong expertise demonstrated the significance of automation when developing the energy system,” says Maria Nurmoranta, Development Manager, Power Automation Development, Valmet.

Profitable operation requires production optimization

Valmet’s experts studied the possibilities of traditional power plants to respond to the requirements of the future energy system and increase predictability in their production. The research focused on the optimal operation of power plants as well as finding their existing flexibility potential and new advanced control solutions to increase flexibility.

Finland’s strong know-how in power and heat cogeneration brings an interesting perspective to increasing flexibility. As CHP plants act as links between electricity and district heating networks, it is possible to utilize the flexibility potential offered by these heating networks and their heat storages to optimize electricity production, too.

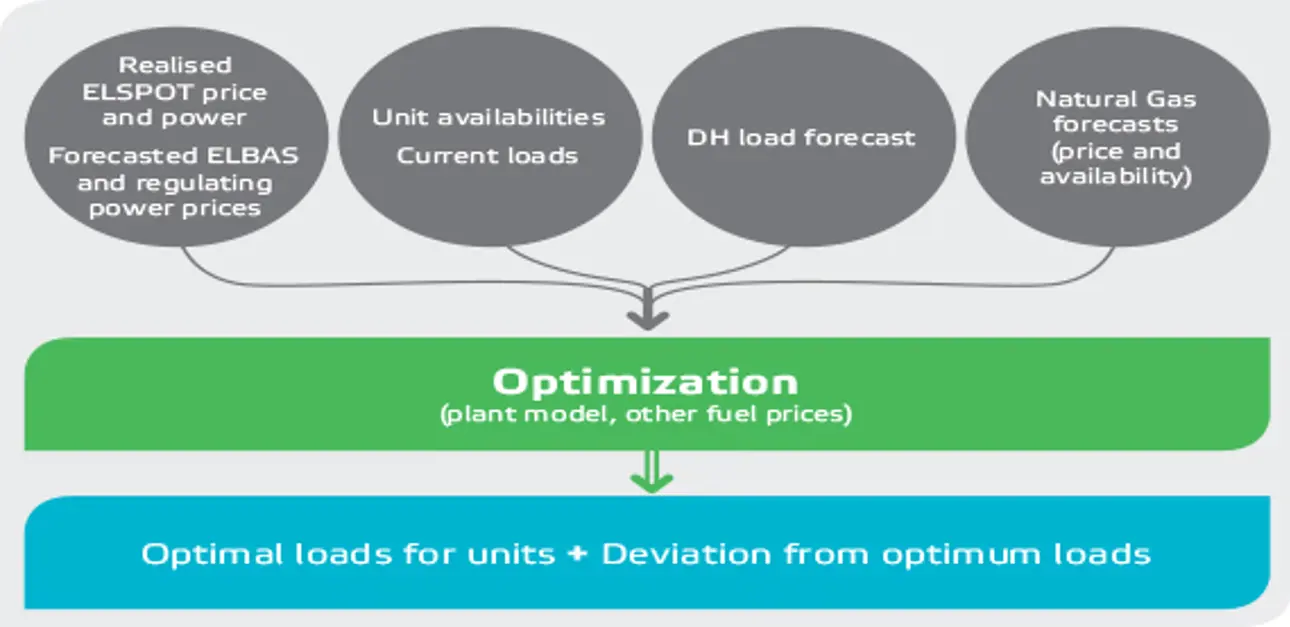

Caption: Optimization of the plant illustrated.

“In this field, Valmet studied district heating network management and optimal operation together with advanced plant-level controls in particular. With such control solutions, these plants will be able to quickly participate in the electricity grid’s frequency support,” Nurmoranta underlines.

Additionally, Valmet focused on the management of a power boiler’s mechanical performance as well as studied the process in load change situations and the ways of reaching ultra-minimum loads. The target is to develop process solutions that fulfill the future performance needs of a plant without jeopardizing its durability and efficiency.

“Changes taking place in the energy market increase the periods of both cheap and expensive energy price levels. To keep CHP plant operation profitable, it is increasingly important to optimize electricity production. The optimal usage of production plants and district heating networks requires new and more advanced control solutions, both at the plant level and in operating the district heating network. When the electricity price is high, it obviously pays off to produce more electricity. But when the price is low, it is possible to run the plants only with a minimum load that is sufficient to secure the customers’ need for heat,” Nurmoranta explains.

“The plants have to be able to run with lower loads than earlier and respond to the increasingly faster changes in the energy grid, while keeping within the emissions limits set for them. This requires rethinking the plant structure and the way it is operated,” Mäkinen adds.

Information about the FLEXe program

The aim of the FLEXe program was to enhance the transition from current energy systems to sustainable ones that combine smartness, environmental performance and economic success.

It focused on the profound transformation in the energy systems towards a sustainable energy system of the future. A global need to reduce greenhouse gas emissions has strengthened the share of renewable energy production forms, such as naturally occurring wind and solar energy, in the energy system. To support this development, new and flexible solutions are needed to guarantee sufficient energy generation during changing weather conditions, too.

Other global trends include the shift from oil to gas, an increase in energy demand, especially in developing economies, decentralization of energy production and market globalization.

Caption: Highly flexible CFB boiler for CHP plants.

The program’s participants included strong players in the related industries and the research world, all with extensive know-how of the entire value chain of energy systems. There were 17 companies and 10 universities or research institutes involved. The program started in January 2015 and was concluded in the autumn of 2016. It was coordinated by CLIC Innovation Oy, a Finnish innovation cluster, and funded by Tekes, Finnish Funding Agency for Technology and Innovations.

More information:

Maria Nurmoranta

maria.nurmoranta at valmet.com